This install is 98% done for me. My CB 6048 is working great heating my house and workshop, but I am having trouble with my guesthouse getting air in the pipes which is causing the flow to stop at the pump.

I ran the pipes underground from the boiler, and then up the side of the house, through the attic, and to the boiler room where the Taco 011 pump is 1 foot off the floor.

I keep purging the air out of the lines by running garden hose water through both the supply and return. Air gets pushed back to the wood boiler and everything seems great.

I start the pump back up and it starts running, but still not getting the best flow. After a few hours its bringing hot water to about the pump, but not enough force to push it all back through the exchanger and return to the boiler.

I don't believe there are any leaks in the lines. I have no idea how air is getting in, I am almost cerain there are no leaks, but perhaps I just havent gotten it all out, or its coming in microbubbles and then building up and clogging the lines.

My pump is a bit overkill based on my head calculations, but the other option would have been the 014 and it would have been under so I would rather be over than under.

Should I install an automatic hy-vent and get the air out, on a tee, and put one in supply and one in return, at highest point in the attic? Should I also install another at the inlet before the pump? I do notice air bubbles in the lines being sucked toward the pump after it runs a little while.

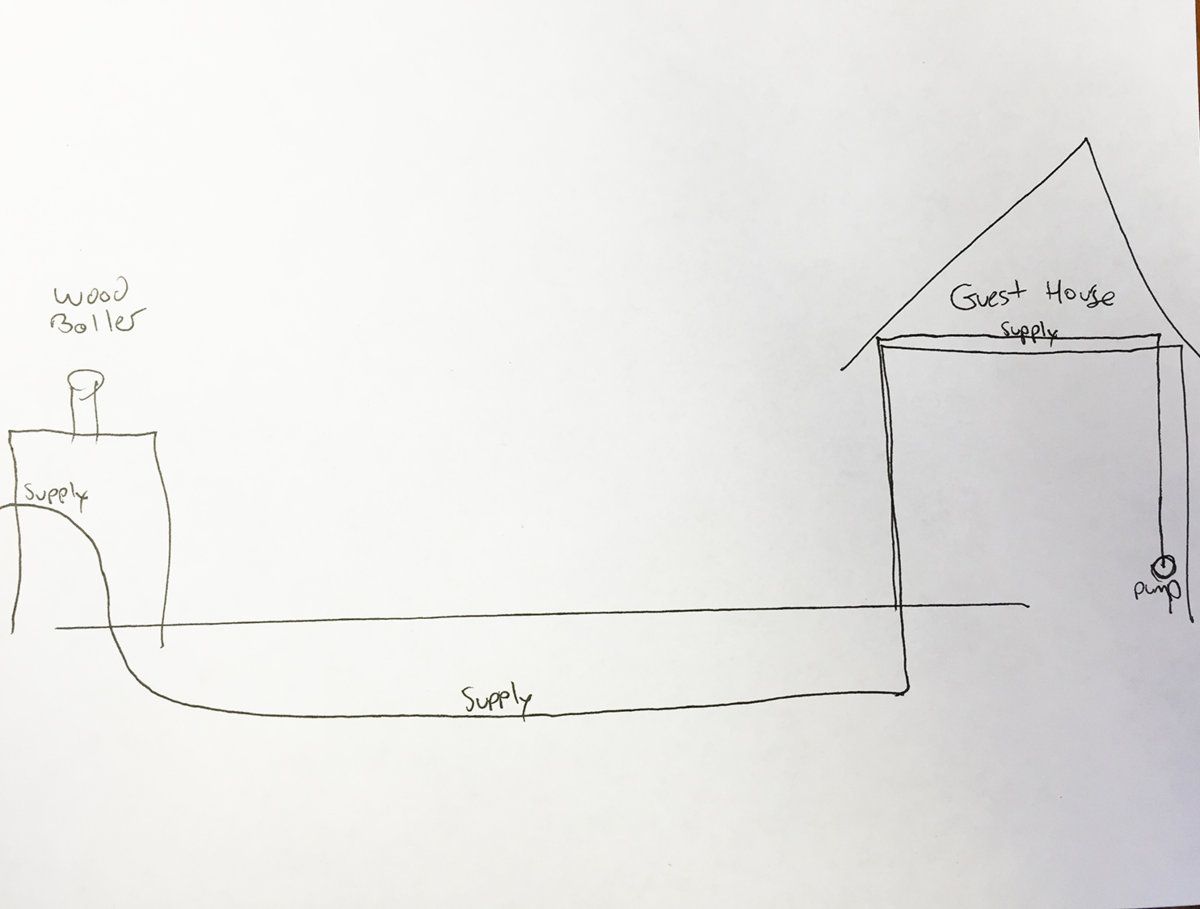

Here is a diagram of my install. I have a slab and septic in the ground so this was my only option. I do not want to pump attached to the wood boiler and I decided to install it in the boiler room line with my shop and house which are working great. Any help you all could give would be appreciated!

I ran the pipes underground from the boiler, and then up the side of the house, through the attic, and to the boiler room where the Taco 011 pump is 1 foot off the floor.

I keep purging the air out of the lines by running garden hose water through both the supply and return. Air gets pushed back to the wood boiler and everything seems great.

I start the pump back up and it starts running, but still not getting the best flow. After a few hours its bringing hot water to about the pump, but not enough force to push it all back through the exchanger and return to the boiler.

I don't believe there are any leaks in the lines. I have no idea how air is getting in, I am almost cerain there are no leaks, but perhaps I just havent gotten it all out, or its coming in microbubbles and then building up and clogging the lines.

My pump is a bit overkill based on my head calculations, but the other option would have been the 014 and it would have been under so I would rather be over than under.

Should I install an automatic hy-vent and get the air out, on a tee, and put one in supply and one in return, at highest point in the attic? Should I also install another at the inlet before the pump? I do notice air bubbles in the lines being sucked toward the pump after it runs a little while.

Here is a diagram of my install. I have a slab and septic in the ground so this was my only option. I do not want to pump attached to the wood boiler and I decided to install it in the boiler room line with my shop and house which are working great. Any help you all could give would be appreciated!

Last edited: