Its been ages since I posted but I joined here originally for advice on what boiler to buy. I ended up buying a Central Boiler 6048 and I really love it. I finished installing it a few weeks ago and have it plumbed up to my home and its working great.

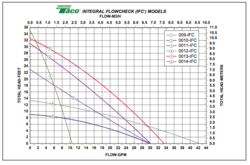

To prepare for winter I need to finish hooking it up to my workshop. I ran the underground thermopex differently to my workshop because of my set up so I have no idea what Taco pump to get. I always buy Taco.

My boiler is sitting near my workshop. My line runs from the boiler, underground to my shop, through the floor of the shop and up to the rafters, and then 40 feet to the middle where it meets the forced air boiler. The pex is 1". Total pex run round trip is no more than 200 feet. There will be 2 elbows, but possibly 4. I plan on mounting the pump near the rafters in my shop, but then the pump will be mounted higher than the boiler by just a few feet. The heat exchanger I got is 230k BTU, that is the amount I need, and the size that fits in my plenum.

I want to get the correct pump but don't know much about head calc with the elbows and everything, and was hoping for some input. I want to make sure I move the right amount of water. Any suggestions will be much appreciated.

To prepare for winter I need to finish hooking it up to my workshop. I ran the underground thermopex differently to my workshop because of my set up so I have no idea what Taco pump to get. I always buy Taco.

My boiler is sitting near my workshop. My line runs from the boiler, underground to my shop, through the floor of the shop and up to the rafters, and then 40 feet to the middle where it meets the forced air boiler. The pex is 1". Total pex run round trip is no more than 200 feet. There will be 2 elbows, but possibly 4. I plan on mounting the pump near the rafters in my shop, but then the pump will be mounted higher than the boiler by just a few feet. The heat exchanger I got is 230k BTU, that is the amount I need, and the size that fits in my plenum.

I want to get the correct pump but don't know much about head calc with the elbows and everything, and was hoping for some input. I want to make sure I move the right amount of water. Any suggestions will be much appreciated.

the Grundfos Magna is an incredible pump with unlimited adjustability, for medium and larger pumping jobs.

the Grundfos Magna is an incredible pump with unlimited adjustability, for medium and larger pumping jobs.