I have filled my system, purged all the air. I cant seem to get my water moving, I even put a beefy 011 taco temporarily in place of the 007. I have studied at my plumbing scheme for hours rechecking. It all acts like a valve is closed.

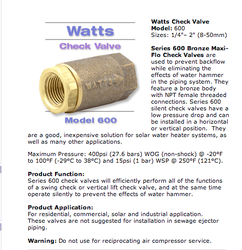

Can a check valve be to strong to let the water circulate? Before I put it in it did seem a little stiff with the push of the finger. It is the only thing I can think of that can be my problem. If it werent so tough to change out I would not even ask, but its buried in threaded pipe. Curses!

Can I use a swing check instead, and what is the difference?

Can a check valve be to strong to let the water circulate? Before I put it in it did seem a little stiff with the push of the finger. It is the only thing I can think of that can be my problem. If it werent so tough to change out I would not even ask, but its buried in threaded pipe. Curses!

Can I use a swing check instead, and what is the difference?