tarm solo 40 states the chimney draft must be 0.04 - 0.05 in. wc please explain. what is the recommended flue size? I recently built 20X20 brick chimney with a 12X12 flue inside; height is approx 30' a jotul 118cb is hooked to the 8 in. thimble now; condensing water on the floor after a burn; no rain that day. i can see it dripping in the cleanout. when I switch over to the tarm will it dry out? Is the flue to big? recommendations please! sweetheat

chimney draft and flue size for tarm 40

- Thread starter sweetheat

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Reggie Dunlap

Feeling the Heat

Your flue is too big, and most stoves work better with a round flue. Tarm says you can use 6" or 8" for the 40. The collar on the boiler is 6", so that is what I used.

You should consider installing a 6" stainless liner and not venting directly into the 12 x 12. Is your chimney interior?

You should consider installing a 6" stainless liner and not venting directly into the 12 x 12. Is your chimney interior?

jebatty

Minister of Fire

Sounds like the Tarm will be a new venture for you. I installed mine last fall and after finishing one season, very impressed and pleased.

The Tarm 40 manual says 6" or 8" ID lined masonry or manufactured HT flue. I installed the 6" ID double wall, insulated, stainless chimney flue, total height, including 5" of black stove pipe to ceiling, is about 22', and installed proper horizontal distance from roof and in excess of minimum over the roof peak. In my installation, and burning pine mostly, I was getting too much draft, and I had to close the draft fan damper quite a bit to keep the temperature down in the Tarm. I also installed turbulators (the chain type -- do a search on this forum for a description). My flue temps now are in the 400-450 range with peaks at near 600. Have not needed to clean the chimney the entire season, but will clean it when the heating season finally ends. Once a year should do it, which I attribute in part to the very clean burning of the Tarm and in part to maintaining flue temps high enough to insure no condensation.

As I don't have a masonry chimney, my comments are a little speculative. You say a 12 x 12 flue. This is in excess of what the manual states; should be 6 or 8 ID. It may produce excess draft. Also, condensation may be coming from fresh masonry with moisture that hasn't yet been evaporated out; may be a result of a large cold masonry taking a long time to heat up and evaporate moisture in the masonry and condensation from flue gases.

Personally, I would recommend a 6" or 8" (I'm partial to 6" stainless because that's what I have and it works well) stainless liner or flue. That should heat quickly and keep the flue gases away from the large cold masonry mass. You will want to experiment a bit with flue temp to see what you need to prevent condensation. Comments on this forum suggest no less than 300; personally I would go for a steady 400 to minimize condensation issues and possible creosote issues. With a 30' flue you also may experience excess draft and will need to limit the draft fan to prevent excess flue temp.

You also will want to experiment to find your best way to get a hot fire going quickly, no slow starts. I have found that within 5-10 minutes I will have a very good fire blasting into the refractory. I start with a small quantity of smaller kindling, then add more after the fire takes strongly, then fill the firebox. I fill and walk away. Smaller splits/rounds work much better than larger. Manual says 4-5" works best; probably true.

With my setup there has been no dripping condensation or other ooze ever, even when firing the Tarm with outside temps well below zero. In my install the entire chimney above the ceiling is in an unheated attic space, so the flue does get very cold.

Good luck.

The Tarm 40 manual says 6" or 8" ID lined masonry or manufactured HT flue. I installed the 6" ID double wall, insulated, stainless chimney flue, total height, including 5" of black stove pipe to ceiling, is about 22', and installed proper horizontal distance from roof and in excess of minimum over the roof peak. In my installation, and burning pine mostly, I was getting too much draft, and I had to close the draft fan damper quite a bit to keep the temperature down in the Tarm. I also installed turbulators (the chain type -- do a search on this forum for a description). My flue temps now are in the 400-450 range with peaks at near 600. Have not needed to clean the chimney the entire season, but will clean it when the heating season finally ends. Once a year should do it, which I attribute in part to the very clean burning of the Tarm and in part to maintaining flue temps high enough to insure no condensation.

As I don't have a masonry chimney, my comments are a little speculative. You say a 12 x 12 flue. This is in excess of what the manual states; should be 6 or 8 ID. It may produce excess draft. Also, condensation may be coming from fresh masonry with moisture that hasn't yet been evaporated out; may be a result of a large cold masonry taking a long time to heat up and evaporate moisture in the masonry and condensation from flue gases.

Personally, I would recommend a 6" or 8" (I'm partial to 6" stainless because that's what I have and it works well) stainless liner or flue. That should heat quickly and keep the flue gases away from the large cold masonry mass. You will want to experiment a bit with flue temp to see what you need to prevent condensation. Comments on this forum suggest no less than 300; personally I would go for a steady 400 to minimize condensation issues and possible creosote issues. With a 30' flue you also may experience excess draft and will need to limit the draft fan to prevent excess flue temp.

You also will want to experiment to find your best way to get a hot fire going quickly, no slow starts. I have found that within 5-10 minutes I will have a very good fire blasting into the refractory. I start with a small quantity of smaller kindling, then add more after the fire takes strongly, then fill the firebox. I fill and walk away. Smaller splits/rounds work much better than larger. Manual says 4-5" works best; probably true.

With my setup there has been no dripping condensation or other ooze ever, even when firing the Tarm with outside temps well below zero. In my install the entire chimney above the ceiling is in an unheated attic space, so the flue does get very cold.

Good luck.

thanks for the input RD and Jim. Yes the chimney is interior and was built to accommodate the new tarm and the jotul 118 going on the 2nd floor. oh well hind sight is 20/20. Now my question is should I direct vent the new set-up (roof's on) or line the inside of the new 12X12 masonry chimney with stainless round? How would you ever clean it inside the 12X12 masonry? HT is high temp I assume? Is their an explanation of plumbing terms and abbreviation's here for the newbie? Will nfpa code allow 2 stainless 6" flues in a 12X12 masonry chimney? OD of 6" stainless is 8" I beleive. thanks sweetheat

jebatty

Minister of Fire

OD of HT 6" is 8". You may be able to go with just a stainless liner at 6", but I don't know anything about that. Also have no code knowledge. Cleaning would be about the same as cleaning the masonry. Just need an access point, or clean down from the roof and then clean out at the entry to the house.

Hindsight is great - rarely fails.

Hindsight is great - rarely fails.

Thanks, my hind sight is kickin in. so a stainless liner all the up. Any recommendations where to look for the plumbing lingo abbreviations plumber sign language? sweetheat

Gooserider

Mod Emeritus

Lots of discusion of chimney liners and such in the hearth room - essentially it sounds to me like you can put in a liner to vent one appliance in your existing chimney, but not two.

Gooserider

Gooserider

Thanks for the input gooserider. Inside of the 12X12 is approx 11 inches. If I install a 6 inch liner to the tarm would it be possible to install another 4 inch to the jotul? Is this against NFPA code/reg's? Any thoughts about duravent by simpson? What else is available?

Gooserider

Mod Emeritus

As I understand it, the rules say that in order to put multiple flue pipes in the same chimney structure, each must be insulated from the other, so you would have to put a 1/2" insulation jacket around EACH of the two liners, which isn't going to fit... (Not to mention that you have to have 6" for the Jotul as well...) It sounds like you may need to put one appliance up your existing chimney with a 6" liner, and then put in a prefab chimney for the other. (It is absolutely NOT OK to have two appliances sharing the same flue...)

The Simpson Duravent is reasonably good stuff, never heard anything bad about it. Essentially all the UL listed HT venting products are pretty good, and are fairly comparable in quality, so I don't see a huge reason to prefer one over another.

Gooserider

The Simpson Duravent is reasonably good stuff, never heard anything bad about it. Essentially all the UL listed HT venting products are pretty good, and are fairly comparable in quality, so I don't see a huge reason to prefer one over another.

Gooserider

free75degrees

New Member

Putting in a prefab chimney may sound like a big job, but I don't this is too hard. Selkirk Metalbestos has a nice web site that explains all the parts that you will need to buy and you can then buy all the parts from various online stores (I got mine from Unifire, which was the cheapest I could find). They only need 2 inches from combustibles and the chimney top has to be 3 feet higher than where it exits the roof and 2 feet higher than any point within 10 feet.

jebatty

Minister of Fire

The prefab chimneys almost are a no-brainer. I put my first one in 18 years ago, and still going strong. That was for the wood stove, still in use, same stove. Last fall in my shop installed a gasification boiler and put in the second one. Even easier this time, just get it plumb. They are safe, secure, and perform well.

webbie

Seasoned Moderator

I don't see a problem with putting a 6 inch liner down to the Tarm and then a 5" liner (would this fit?) down to the Jotul. I think it might fit on a diagonal.

There are probably ways to slightly separate the two even then (I'll have to sketch this up to see the fit), although again - given their installation in an existing safe chimney, I don't see the problem. If anyone can point me to a potential problem with this, I am all ears.

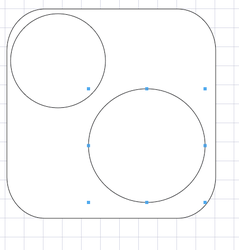

Enclosed shows one 6 and one 5 in 11 sq. chimney.

Should be fine - use rigid pipe - like Heat-fab.

Goose, Jotul 118 had 4.7" flue......

There are probably ways to slightly separate the two even then (I'll have to sketch this up to see the fit), although again - given their installation in an existing safe chimney, I don't see the problem. If anyone can point me to a potential problem with this, I am all ears.

Enclosed shows one 6 and one 5 in 11 sq. chimney.

Should be fine - use rigid pipe - like Heat-fab.

Goose, Jotul 118 had 4.7" flue......

Attachments

Thanks to all for your input. I'll send photos when it's all together. I guess I'll remove my chimney cap and start up there with 4' sections of 6" stainless pipe/with insulation. The jotul will be on the 2nd floor so I'll start at the top and drop sections down to the 2nd floor thimble and work my way up. The hind sight is telling me to tie it all off good as I connect sections and drop them down. I'll secure it all at the top with a collar designed to hold 2 sections of pipe. Any other thoughts are most welcome. What about flexable stainless pipe. Same stuff, but already connected together. Would you have thoughts on that? thanks sweetheat

webbie

Seasoned Moderator

Flex has a larger OD (outside diameter) than Rigid......so you have do the scale drawing or map it out to make certain of fit.

Flex is also a different product, and does not draft as well - because the inside is not smooth (there are some exceptions).

Flex is also much thinner.

That all said, it is fine if it works out.

You can use a rope run through the center of the pipe to lower it. Sections of rigid are screwed or riveted together as you drop them. Rivets probably do a better job. The rope can either be tethered or held by a second person as you lower the pipe.

Flex is also a different product, and does not draft as well - because the inside is not smooth (there are some exceptions).

Flex is also much thinner.

That all said, it is fine if it works out.

You can use a rope run through the center of the pipe to lower it. Sections of rigid are screwed or riveted together as you drop them. Rivets probably do a better job. The rope can either be tethered or held by a second person as you lower the pipe.

- Status

- Not open for further replies.

Similar threads

- Replies

- 11

- Views

- 448

- Replies

- 16

- Views

- 2K

- Replies

- 1

- Views

- 790

- Replies

- 0

- Views

- 736