Had the big lift over at my house, from work, today. Was there to do some tree trimming, but while I had it, figured I'd finally go up and check out my existing chimney.

EE-EEK!

EE-EEK!

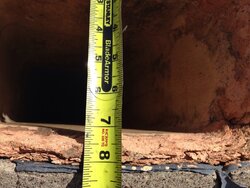

Long story short, I've got a 6 1/2" x 12"(I.D.) clay liner that's got chips, cracks, and a top edge that has literally just crumbled from freeze/thaw cycles. The question is, can I find a solid oval liner, for this, that won't break the bank, or should I just go with something like a Selkirk Supervent? I think the liner would be the easiest fix, perhaps with pour in insulation. But after the extra work to put in a metal class A chimney, I could have a straight up pipe, into the chimney, as opposed to a traditional stove pipe with the bend to get it into the existing (now lined) masonry unit. The metal chimney would entail a chase, as it would pass through two floors, etc.

The front corner on the left of the image is the corner of the existing chimney. If you look at the upper left, you can just see the old flue, now cemented in. If this is lined and used, the stove would be in the corner, with double wall pipe making its way to this, or a new (legally spaced) flue. With a metal class A, there are many options, the most likely of which is the opposite corner. This would run the chimney through an upstairs storage area, in the eaves of the 1 1/2 story house. It would also necessitate a pretty tall chimney, outside, as I have about an 8/12 pitch to the roof. It would, however, mean that all I'd have to do to clean the chimney is bring home the lift, drive up to the thing, and viola! One pipe, cleaned.

So, oh wise-ish and woodsy ones, any thoughts on this? Am I missing something obvious? I'm genuinely 50/50 on which I'd rather have, and am looking for both advice and opinions, if you're willing to give them. If more pics are needed, no problem.

EE-EEK!

EE-EEK!

Long story short, I've got a 6 1/2" x 12"(I.D.) clay liner that's got chips, cracks, and a top edge that has literally just crumbled from freeze/thaw cycles. The question is, can I find a solid oval liner, for this, that won't break the bank, or should I just go with something like a Selkirk Supervent? I think the liner would be the easiest fix, perhaps with pour in insulation. But after the extra work to put in a metal class A chimney, I could have a straight up pipe, into the chimney, as opposed to a traditional stove pipe with the bend to get it into the existing (now lined) masonry unit. The metal chimney would entail a chase, as it would pass through two floors, etc.

The front corner on the left of the image is the corner of the existing chimney. If you look at the upper left, you can just see the old flue, now cemented in. If this is lined and used, the stove would be in the corner, with double wall pipe making its way to this, or a new (legally spaced) flue. With a metal class A, there are many options, the most likely of which is the opposite corner. This would run the chimney through an upstairs storage area, in the eaves of the 1 1/2 story house. It would also necessitate a pretty tall chimney, outside, as I have about an 8/12 pitch to the roof. It would, however, mean that all I'd have to do to clean the chimney is bring home the lift, drive up to the thing, and viola! One pipe, cleaned.

So, oh wise-ish and woodsy ones, any thoughts on this? Am I missing something obvious? I'm genuinely 50/50 on which I'd rather have, and am looking for both advice and opinions, if you're willing to give them. If more pics are needed, no problem.

Last edited: