Chimney questions

- Thread starter warno

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

woodsmaster

Minister of Fire

I would split the wood a little smaller to get the fire going and up to temp quicker, and try to leave a little more charcoal for starting the next fire.

Fred61

Minister of Fire

My assumption is that you will not be able to burn the smoke if the oxygen is depleted from the combustion air by the time it reaches the middle or top of the load regardless of how far your inlet damper is open.

My dad has been telling me basically the samething. on his wood furnace in his basement the air damper, natural draft, pulls air directly into the coal bed from the front of the furnace. but his furnace has the smoke channel above which means his smoke leaves the front to go over top of the fire to get reburned before leaving up the flue. maybe I should redirect my air flow into my coal bed and see what happens.

Fred61

Minister of Fire

That channel needs to have enough air and enough heat to ignite the gasses. You need both. His apparently has them if it is not a "smoker".

stee6043

Minister of Fire

I must say, warno, you're probably one of the most caring suburban wood burners out there! Most folks wouldn't put half of your effort into understanding their wood burners and trying to improve.

Keep up the good work. If I were in your shoes I'd combine a couple of the suggestions above - 1.) put more chimney up, as much as you can handle, 2.) start your fires with small, super dry splits and 3.) try to leave some coals from the prior fire in the bottom if you can. Many of us gasser owners use a cheapo 110v timer to accomplish #3. It can be a big helper...

Keep up the good work. If I were in your shoes I'd combine a couple of the suggestions above - 1.) put more chimney up, as much as you can handle, 2.) start your fires with small, super dry splits and 3.) try to leave some coals from the prior fire in the bottom if you can. Many of us gasser owners use a cheapo 110v timer to accomplish #3. It can be a big helper...

Thank you. I'm trying to do my best. I know the smoke is offensive and I don't want to be the problem in the neighborhood if I can avoid it. But, having a homebuilt unit allows me to change and try new things without voiding any warranty.

All my control is based off my flue temp. it's a truly simple control system though. it only uses one relay to shut things down after flue temp gets back down to my "shut down" setting. so if I find a setting that leaves a good amount of charcoal behind I'll stick with that. I'm thinking that's around where I'm at now with 240 shut down temp. I'm going to try changing my air input soon.

All my control is based off my flue temp. it's a truly simple control system though. it only uses one relay to shut things down after flue temp gets back down to my "shut down" setting. so if I find a setting that leaves a good amount of charcoal behind I'll stick with that. I'm thinking that's around where I'm at now with 240 shut down temp. I'm going to try changing my air input soon.

brenndatomu

Minister of Fire

So your secondary air is routed into the top of the firebox? If so then yeah the water cooled steel is probably keeping things too cool to fire off the reburn. It takes somewheres 1200* to make that happen. The way most newer "EPA" style wood furnaces are setup is that the firebox is totally insulated with firebrick on the sides and a ceramic insulation board at the top that sets right on the secondary air tubes. There is not much heat to be had directly from the firebox, rather they want the temp up as high as possible to burn everything off, then rely on the heat exchanger to capture heat from the flue gasses on their way out...much like your set up I believe.

That ceramic insulation board can be had on fleabay and the like in many different sizes...not that cheap though...

That ceramic insulation board can be had on fleabay and the like in many different sizes...not that cheap though...

I kind of hate to do it because I'm already seeing flue temps up to 600 degrees but I could completely line my fire box with fire brick to insulate it completely from the water jacket. I mean the water would get some radiant through the brick but I would be relying solely on my heat exchanger to get 90%, or better, of the heat from the flue gasses. I do have a turbulator idea that I can implement. how much would this help? my firebox started life as a 120 gallon propane tank, so it's completely round inside.

brenndatomu

Minister of Fire

600* is about where my furnace runs when the intake damper is wide open. How many CFM is your combustion fan? Maybe with a taller chimney you could line the firebox, and then rely on natural draft induction. That would slow the exhaust down more and maybe give you more heat and lower chimney temps? Is the secondary air forced air too?

brenndatomu

Minister of Fire

I bet you're rightThe secondary tube was fed with a fan as well. which is probably why it wasn't firing.

brenndatomu

Minister of Fire

I would think you would want natural draft only (for both primary and secondary) so the air velocity would be low enough to pick up as much heat as possible...(remember that 1200* mark)Should the secondary tube be natural draft only or can some induced air flow be ok?

And like I said, slowing things down will help your HE better work too. You may be surprised how much a taller chimney would improve natural draft....you could just scab up some cheap single wall stove pipe to extend the chimney temporarily for testing purposes

Last edited:

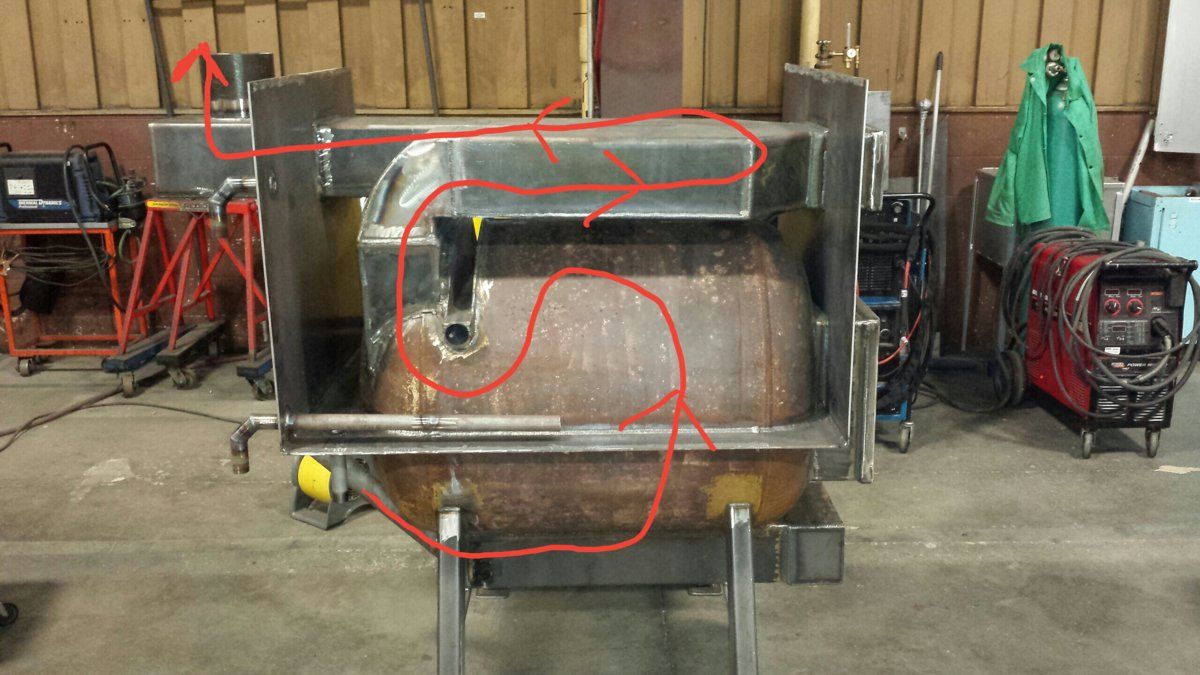

I tried to dig up the best picture I have "side view" of when I was building my boiler to show where my air flow is entering.

So here it is. you can see where my water jacket falls on the fire box, my heat exchanger box, and my air flow pipe. the blue arrow is showing current air flow coming in under the fire grate (red line).

And this is what I'm thinking about doing to get my air flow up into the back of the coal bed. I have 2 weld elbows that I'm going to add in to get the air up above the fire grate.

I know it's rough drawings but will this possibly help with getting the air where I need it?

So here it is. you can see where my water jacket falls on the fire box, my heat exchanger box, and my air flow pipe. the blue arrow is showing current air flow coming in under the fire grate (red line).

And this is what I'm thinking about doing to get my air flow up into the back of the coal bed. I have 2 weld elbows that I'm going to add in to get the air up above the fire grate.

I know it's rough drawings but will this possibly help with getting the air where I need it?

maple1

Minister of Fire

This is partly some wild speculation, but I'm thinking you might have something there that might be able to be turned into something with some gasification to it. Via creative use of firebricking, & airflow routing.

brenndatomu

Minister of Fire

So the secondary air pipe will run through the coals before turning up to the top? That would make for some hot coals once you get to that point in the combustion cycle (probably coals there all the time once full time burning is commenced)I tried to dig up the best picture I have "side view" of when I was building my boiler to show where my air flow is entering.

So here it is. you can see where my water jacket falls on the fire box, my heat exchanger box, and my air flow pipe. the blue arrow is showing current air flow coming in under the fire grate (red line).

View attachment 188108

And this is what I'm thinking about doing to get my air flow up into the back of the coal bed. I have 2 weld elbows that I'm going to add in to get the air up above the fire grate.

View attachment 188109

I know it's rough drawings but will this possibly help with getting the air where I need it?

TCaldwell

Minister of Fire

As stated the placement of the primary should be directed at the wood, not under it. Preheating the secondary is also optimum, can you mark up a photo of the secondary air flow and flue entrance. Secondary air requires time to mix with the wood gas and combust in a insulated or refractory area. Because of your boilers relatively low overall output this area wouldn't have to very large, can you allocate 25pct of the overall firebox to this? Also the primary and secondary air need to be controlled or allocated in a adjustable way like dampers for tuning pirposes

Ok so as of right now here how air flows through my boiler, into the exchanger and out the flue. the fan blows air in the ash pan which comes up through the front of the fire grate, it then rises to the top of the fire box and had to go under the water filled baffle then into the heat exchanger. it then travels forward where it turns and travels back, then exits out the flue.

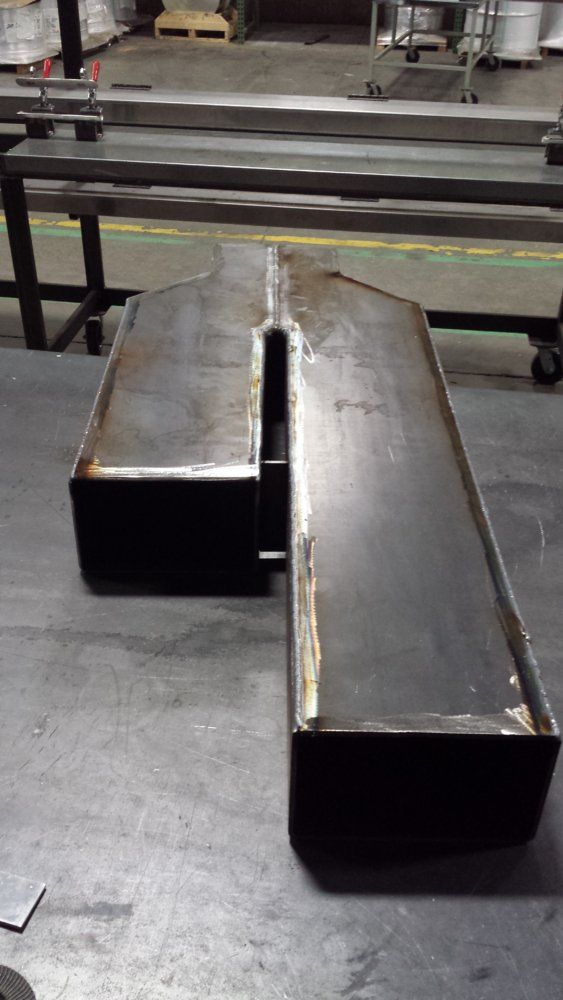

This is what my heat exchanger looks like

And here is how my secondary air is coming in.

It enters the boiler right next to the primary air but is driven into the fire grate via this drop down piece

Then it travels forward in the 3 left tubes of the grate and turns at the front to go back the 3 right tubes and up into the branch.

And here's the branch with the holes marked in circles.

The branch is mounted right below my water cooled baffle which maybe causing too much cooling preventing any secondary firing. would it be wise to move my secondary branch out over top of the fire? just to see if that helps before completely rebuilding everything else.

This is what my heat exchanger looks like

And here is how my secondary air is coming in.

It enters the boiler right next to the primary air but is driven into the fire grate via this drop down piece

Then it travels forward in the 3 left tubes of the grate and turns at the front to go back the 3 right tubes and up into the branch.

And here's the branch with the holes marked in circles.

The branch is mounted right below my water cooled baffle which maybe causing too much cooling preventing any secondary firing. would it be wise to move my secondary branch out over top of the fire? just to see if that helps before completely rebuilding everything else.

Fred61

Minister of Fire

Correct me if I'm wrong but what I see in the non smoking (gassers) boilers is that the secondary combustion has already occurred by the time the gasses reach the point where the steel vessel is exposed to the fire. It may not be possible to get secondary burn if the water jacket is cooling the gasses. On my EKO the smoke is already burned by the time it goes through the heat exchanger.

Unless this experiment is easy and cheap to accomplish it may not be worth the time and money.

Also, the fire needs to burn with a minimal amount of air. I have the combustion fan dialed down so slow it barely starts but the flame in the lower chamber would be described as "violent" when viewed at full burn.

Unless this experiment is easy and cheap to accomplish it may not be worth the time and money.

Also, the fire needs to burn with a minimal amount of air. I have the combustion fan dialed down so slow it barely starts but the flame in the lower chamber would be described as "violent" when viewed at full burn.

- Status

- Not open for further replies.

Similar threads

- Replies

- 20

- Views

- 867

- Replies

- 0

- Views

- 726

- Replies

- 4

- Views

- 754

- Replies

- 2

- Views

- 382