- Oct 3, 2007

- 1,539

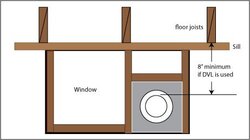

I am planning on installing an Englander 28-3500 add on furnace and I'm lucky enough to have what I think is an ideal layout in my basement. On the west wall of my house there is a basement window which is not far (about 8 feet) from my oil burner. The window is a standard basement window size (about 32" x 19" give or take) and would provide plenty of room to bring the chimney pipe through. The construction of the opening is such that the foundation wall (cinder block) makes up the bottom and sides of the window, but the top edge is actually the sill plate of the house. So basically the top is combustible and the bottom and sides are not. Given that, what's the best way to bring the chimney through the wall? I'm not all that familiar with how thimbles are properly used, etc...but basically it looks to me like the chimney pipe passes through the thimble, which simply acts as a spacer to provide an air gap-is that correct? If so, would it be ok to simply mount the thimble (the correct size for 6" Class A double wall pipe) in the opening with the thimble resting on the bottom (non-combustible) edge of the window opening, and closing in the rest of the opening with bricks and mortar? This way the layers of protection for the combustible wood sill plate above the pipe would be as follows:

-Insulation layer inside chimney pipe

-Air gap inside thimble

-Approximately 10" of non-combustible materials (bricks/mortar)

And now a follow up question-once the thimble is installed in the wall and the chimney pipe is passed through, then what? Is a tee simply attached to the outside (with a proper support brace on the bottom), redirecting the chimney upward at that point? Now to the inside-do I simply connect black stove pipe to the Class A sticking out of the thimble with an elbow and connect that to the stove itself? Sorry for all of the convoluted questions, but I'm trying to get an idea of what I need to buy. I have a source for my chimney pipe and related pieces (bottom support, wall bands, cap, etc...), so if all I need is a thimble, some bricks, and a bag of mortar mix, I don't need the $350 Duravent kit from Home Depot right?

*EDIT*

I just realized that I posted this in the boiler room when it should probably have gone in the hearth room-mods, please move it if it should be moved.

-Insulation layer inside chimney pipe

-Air gap inside thimble

-Approximately 10" of non-combustible materials (bricks/mortar)

And now a follow up question-once the thimble is installed in the wall and the chimney pipe is passed through, then what? Is a tee simply attached to the outside (with a proper support brace on the bottom), redirecting the chimney upward at that point? Now to the inside-do I simply connect black stove pipe to the Class A sticking out of the thimble with an elbow and connect that to the stove itself? Sorry for all of the convoluted questions, but I'm trying to get an idea of what I need to buy. I have a source for my chimney pipe and related pieces (bottom support, wall bands, cap, etc...), so if all I need is a thimble, some bricks, and a bag of mortar mix, I don't need the $350 Duravent kit from Home Depot right?

*EDIT*

I just realized that I posted this in the boiler room when it should probably have gone in the hearth room-mods, please move it if it should be moved.