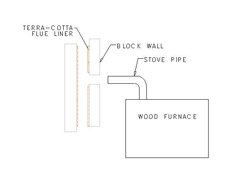

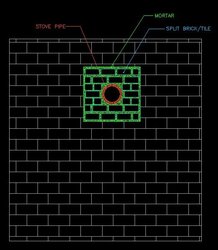

I need to tie the stovepipe from my wood furnace into an existing terracotta lined chimney. The chimney has a 10"x10" opening cut in it, and the stovepipe I am using is 6" round. The question I have is, do I need to do anything special to make the connection between the two, or just run enough stovepipe into the chimney?? Please keep in mind this is all contained in foundation block work. See the attached picture for clarification. Any and all help is appreciated!!

Chimney to Stovepipe transition

- Thread starter dmaves

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I would insert a terra cotta round liner as a thimble that is 6 inches in diameter and mortar it into the chimney. The thing you need to be careful of is that the 6 inch metal stove pipe must NOT extend into the chimney itself. It must stop short or flush. Often times this is the job of the clay liner w/ the hole in it (it would work as a stop having a hole smaller than your stove pipe going through the thimble). Instead, you could cut a piece of single wall pipe down so that the lip on the male side would rest on the outer lip of the round clay thimble and it would be impossible to push it in far enough to block the chimney / have creosote land on it and catch.

Ever think about lining this chimney w/ a SS liner? Is the diameter of the terracotta 10x10 as well? If so, it should be an easy line and would certainly help w/ the creosote that wood furnaces often make.

pen

Ever think about lining this chimney w/ a SS liner? Is the diameter of the terracotta 10x10 as well? If so, it should be an easy line and would certainly help w/ the creosote that wood furnaces often make.

pen

brianbeech

Feeling the Heat

I had a sweep install my stove - he busted the hole in the chimney and inserted, what looks to be like, a stainless piece of pipe. The then mortared around it to solidify it and hooked my stovepipe up to it. Seems to work fine, but looking back, I would have liked a clay thimble-type of adjustment. Of course, then I wouldn't have been able to screw it together like I have with the setup I have now.

pen said:I would insert a terra cotta round liner as a thimble that is 6 inches in diameter and mortar it into the chimney. The thing you need to be careful of is that the 6 inch metal stove pipe must NOT extend into the chimney itself. It must stop short or flush. Often times this is the job of the clay liner w/ the hole in it (it would work as a stop having a hole smaller than your stove pipe going through the thimble). Instead, you could cut a piece of single wall pipe down so that the lip on the male side would rest on the outer lip of the round clay thimble and it would be impossible to push it in far enough to block the chimney / have creosote land on it and catch.

Ever think about lining this chimney w/ a SS liner? Is the diameter of the terracotta 10x10 as well? If so, it should be an easy line and would certainly help w/ the creosote that wood furnaces often make.

pen

Pen,

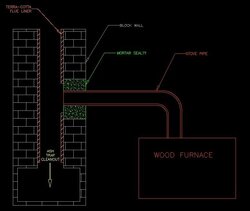

Thanks for the reply; The terracotta liner is rectangle and unsure of the dimensions at this time. So I could still use stovepipe and run this up to the outside of the terracotta liner? Then, what would I do to seal off the rest of the hole around the stovepipe in the terracotta liner? This is the problem I had a question with. The previous owner had just used mortar to halfas* seal off the chimney around the stovepipe, which was all rusted and corroded, which is why I removed it and plan to replace with new. Is this what I would need to do, fill the space around the stovepipe with mortar, sealing off the inside chimney and inside of the block-work? See picture for clarification.

Attachments

I think you misunderstood me. Buy a round, clay thimble and mortar w/ use brick pieces to put it into your 10 inch hole. Don't mortar directly to stove pipe. Then put the stove pipe inside of that. just make sure that they clay thimble and the stove pipe do not protrude into the chimney itself.

Hope that makes sense. Your pic is good, just need a horizontal piece of round clay in there sandwiched between your mortar and the stove pipe.

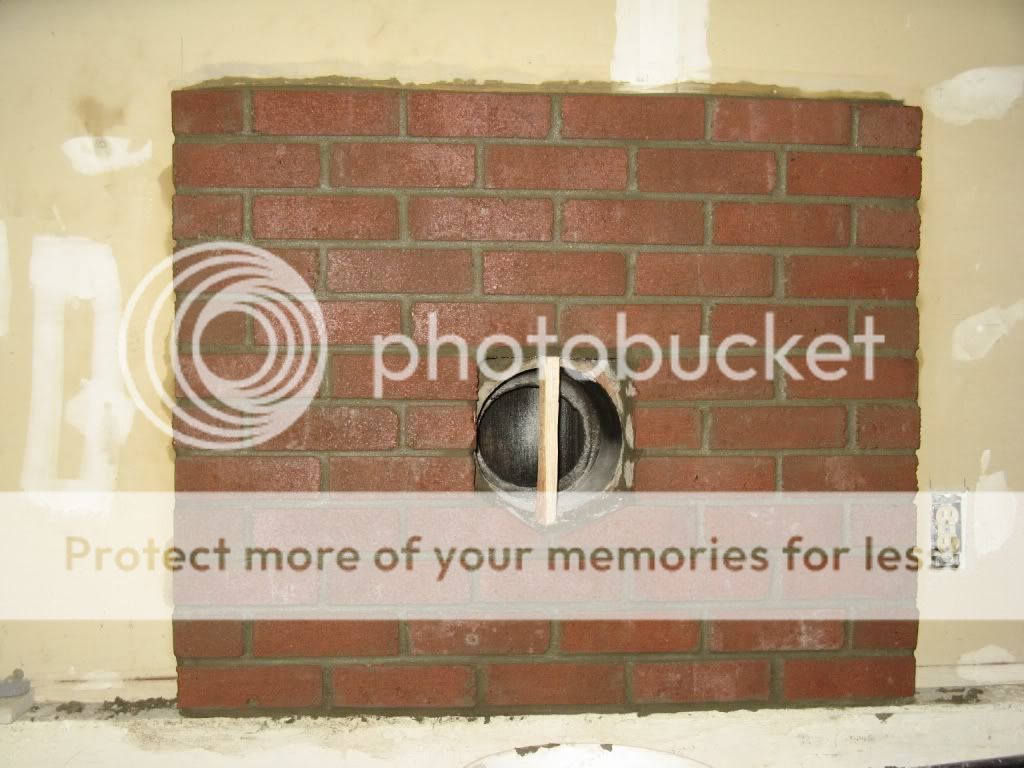

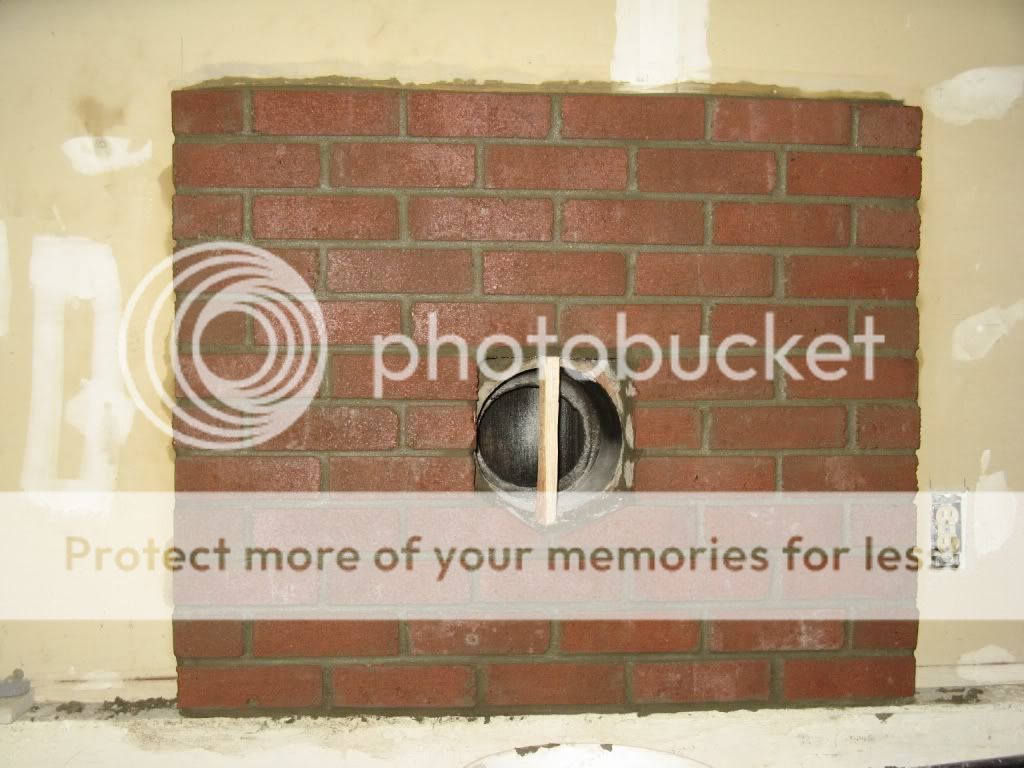

Here's a look at my thimble. You can see the round clay "crock" inside behind the stick holding up the brick. Insert one of these in your huge opening and mortar around it using pieces of brick as you go so that your mortar isn't more than about 1/2 in thick in any given spot.

pen

Hope that makes sense. Your pic is good, just need a horizontal piece of round clay in there sandwiched between your mortar and the stove pipe.

Here's a look at my thimble. You can see the round clay "crock" inside behind the stick holding up the brick. Insert one of these in your huge opening and mortar around it using pieces of brick as you go so that your mortar isn't more than about 1/2 in thick in any given spot.

pen

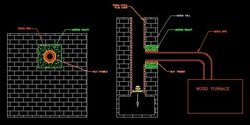

Pen,

How does this look? Any idea as to where I might be able to pick up a clay thimble? How much larger than the stovepipe should I go on the thimble? Have a look at the my updated picture below and let me know if I have the right idea. The only issue I see is sealing around the thimble, as I think the hole in the flue liner will still be larger than the thimble; so I will have to somehow hold the thimble in place while I mortar it into place. Does the stove pipe just rest inside the clay thimble and is not attached in any way?

How does this look? Any idea as to where I might be able to pick up a clay thimble? How much larger than the stovepipe should I go on the thimble? Have a look at the my updated picture below and let me know if I have the right idea. The only issue I see is sealing around the thimble, as I think the hole in the flue liner will still be larger than the thimble; so I will have to somehow hold the thimble in place while I mortar it into place. Does the stove pipe just rest inside the clay thimble and is not attached in any way?

Attachments

You'll want the stove pipe to fit snugly inside the clay thimble.

Just call around the supply houses in your area to find one. The entire piece you show is called the thimble. That clay piece that the pipe will sit in is often called a crock.

A 6 in crock is often going to be 8 inches in outside diameter. You could use split pieces of brick, tile, etc, layered in w/ the mortar as you build up to and around the crock to get your finished thimble. Start at the bottom, once it's high enough to insert the crock do so and build around it w/ the split brick / mortar.

Make sure your crock is positioned so that it tips uphill into the chimney about a 1/4 of an inch per foot of crock that you use.

When hooking your stove pipe up have the male ends pointing down. If you have the room using 2, 45 degree bends going from the stove to the thimble w/ the stove pipe will provide better draft than 1, 90 if draft is a concern.

Just to double check, all the tiles in this chimney are in good order and the chimney is sound for many years of service? I hate to see you do all this on a chimney that may need to be lined w/ SS in short order.

pen

Just call around the supply houses in your area to find one. The entire piece you show is called the thimble. That clay piece that the pipe will sit in is often called a crock.

A 6 in crock is often going to be 8 inches in outside diameter. You could use split pieces of brick, tile, etc, layered in w/ the mortar as you build up to and around the crock to get your finished thimble. Start at the bottom, once it's high enough to insert the crock do so and build around it w/ the split brick / mortar.

Make sure your crock is positioned so that it tips uphill into the chimney about a 1/4 of an inch per foot of crock that you use.

When hooking your stove pipe up have the male ends pointing down. If you have the room using 2, 45 degree bends going from the stove to the thimble w/ the stove pipe will provide better draft than 1, 90 if draft is a concern.

Just to double check, all the tiles in this chimney are in good order and the chimney is sound for many years of service? I hate to see you do all this on a chimney that may need to be lined w/ SS in short order.

pen

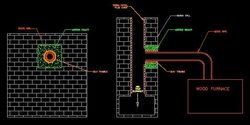

Ok, so where I show the mortar seal (green), you are saying to use split pieces of brick or tile to fill the gap around the clay crock? (See picture representation) The only issue I still see is sealing against the flue liner, as the hole cut into it is so large??

It is hard to say the condition of the chimney until I am able to get it cleaned. I plan to hold off on starting until I get it cleaned out. from what I could get clean through the wall, the liner looked to be in good shape; however, I will know the complete condition after I get it cleaned.

It is hard to say the condition of the chimney until I am able to get it cleaned. I plan to hold off on starting until I get it cleaned out. from what I could get clean through the wall, the liner looked to be in good shape; however, I will know the complete condition after I get it cleaned.

Attachments

yep, you can fill that green area in w/ a combination of brick pieces, and mortar, tile and mortar, etc. The brick or tile will just give the mortar some strength so that it is not a couple inch thick mortar.

Sounds like the plan is coming together.

As far as the back, your mortar / brick combo will be the end of it. No way to patch a piece of tile in there now that I know of that could also be cleaned.

pen

Sounds like the plan is coming together.

As far as the back, your mortar / brick combo will be the end of it. No way to patch a piece of tile in there now that I know of that could also be cleaned.

pen

Ok, thanks Pen; if this is the route I go, I will just try to get the brick/mortar combo as close to the outside of the flue liner as possible, I may have to do some clean-up to the pass-thru hole in the block wall to make it an easier patch. Any suggestions on a mortar to use? Will a standard mortar or mason mix work fine?

Type N will work just fine for you. Type S would also work (little strong, slightly harder to work with but not much).

Type N is commonly used for chimmneys. Type is is for retaining walls more and type M is for high compression.

At the end of the day any of them would work though.

pen

Type N is commonly used for chimmneys. Type is is for retaining walls more and type M is for high compression.

At the end of the day any of them would work though.

pen

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 363

- Replies

- 10

- Views

- 1K

- Replies

- 14

- Views

- 1K

- Replies

- 5

- Views

- 520