Hey folks,

Have been playing with the pump size tool at http://www.taco-hvac.com/uploads/FileLibrary/SelectingCirculators.pdf

Everything seems straight forward until we get to head loss.

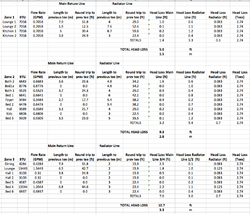

I dont know the pipe length for my 3rd zone as yet, but in my first two zones I used 500ft of AL-PEX total for all pipework, the calculator says I need a flow rate of 14 GPM.

HL = k * c * L * (f ^1.75)

0.0034 * 0.933 * 500 * ( 14 ^1.75 )

=161 ft head

This seems to be off the charts.

Am I including too much pipe?

Have been playing with the pump size tool at http://www.taco-hvac.com/uploads/FileLibrary/SelectingCirculators.pdf

Everything seems straight forward until we get to head loss.

I dont know the pipe length for my 3rd zone as yet, but in my first two zones I used 500ft of AL-PEX total for all pipework, the calculator says I need a flow rate of 14 GPM.

HL = k * c * L * (f ^1.75)

0.0034 * 0.933 * 500 * ( 14 ^1.75 )

=161 ft head

This seems to be off the charts.

Am I including too much pipe?