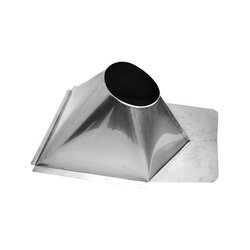

Excel is the only rigid metal roof flashing that I’m aware of.I don't know of another cone style specifically made for metal roofs, but there may be another. @webby3650 has more experience than I with various installs using this product. There are several past posts on the Excel flashing that show installation, etc. with chimney other than Excel.

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.