Hello all. I've been reading thru some posts and have decided that I need to start a thread of my own. In advance I appreciate the help.

I recently purchased a home built in 2001, 2000 square feet, 2 story, and have added a Clayton 1602m that I purchased used from my uncle (furnace is a year old). I'm not too sure about what it's BTU rating is but it has two 800 CFM blowers. Ive installed it and plumbed it into my existing ductwork in the basement. I've burned wood most of my life, but all the stoves have been radiant wood stoves in living rooms.

When I purchased the stove it had a air plenum attached to the top that has two 6inch openings for heat source and a plenum on the rear for cold air return to 8 inch openings.

Now that we have had a few nights that have been below freezing I've had problems keeping the house up to a comfortable temp (70). I'm not too sure what temp is an acceptable/safe range for burn temp. I have a thermometer on the pipe.

Is 450 to high to get the house up to temp before I damp it down? can I get it hotter?

Is my return ducting and heat ducting to and from the furnace adequate?

What temp do most people run there furnaces at?

Is 800 or 1600 CFM adequate? If not can I do anything to move more air?

I know this is kind of long, but I've got a lot of question and a wife and two kids to keep warm. Any advise is appreciated.

Also I have a Woodstock Fire view I'm selling, it was existing in the home.

I recently purchased a home built in 2001, 2000 square feet, 2 story, and have added a Clayton 1602m that I purchased used from my uncle (furnace is a year old). I'm not too sure about what it's BTU rating is but it has two 800 CFM blowers. Ive installed it and plumbed it into my existing ductwork in the basement. I've burned wood most of my life, but all the stoves have been radiant wood stoves in living rooms.

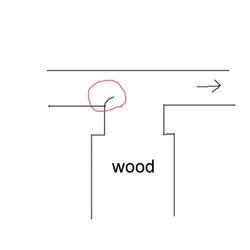

When I purchased the stove it had a air plenum attached to the top that has two 6inch openings for heat source and a plenum on the rear for cold air return to 8 inch openings.

Now that we have had a few nights that have been below freezing I've had problems keeping the house up to a comfortable temp (70). I'm not too sure what temp is an acceptable/safe range for burn temp. I have a thermometer on the pipe.

Is 450 to high to get the house up to temp before I damp it down? can I get it hotter?

Is my return ducting and heat ducting to and from the furnace adequate?

What temp do most people run there furnaces at?

Is 800 or 1600 CFM adequate? If not can I do anything to move more air?

I know this is kind of long, but I've got a lot of question and a wife and two kids to keep warm. Any advise is appreciated.

Also I have a Woodstock Fire view I'm selling, it was existing in the home.

)

)