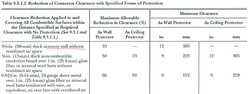

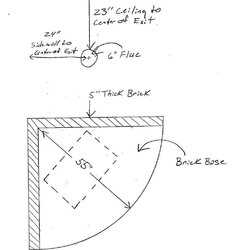

I asked a few questions in this forum on stove installation a couple of weeks ago, all of the responses that I got were great, but unfortunately I still don't have everything straight in my mind. This is primarily due to the fact that the more folks I talk to about stoves the more confused I get What I have is a corner hearth that was existing when we moved in last year. I would like to use this space as is without having to start all over. As you can see from the photo, the hearth is lined with brick, but the brick doesn't have an open air space behind it. Let me rephrase, I believe that it does have an air space as the brick is not tight to the wall, but the space is sealed at the top and bottom with mortar as would be required to reduce clearances. I was at a stove dealer last week and was explaining my set up and the guy there tells me that my clearances will have to be from the front of the brick since the brick will conduct the heat to the wall behind. The first guy told me that I could include the width of the brick as part of my clearance measurement. Who is right??? How is the set up that I have any different then the premade hearth pads that they sell and you throw down over a combustible floor? Any inspectors or professional installers out that can help? When I call the city they tell me whatever the installation instructions for the stove are is what they go by. The city inspector implied over the phone that the width of the brick could be included in the clearance to combustible distance. While this would greatly increase my stove options, I don't want to include it if it is not a safe thing to do. My families safety is my 1st priortiy. Any and all help would be greatly appreciated. Thanks again.

What I have is a corner hearth that was existing when we moved in last year. I would like to use this space as is without having to start all over. As you can see from the photo, the hearth is lined with brick, but the brick doesn't have an open air space behind it. Let me rephrase, I believe that it does have an air space as the brick is not tight to the wall, but the space is sealed at the top and bottom with mortar as would be required to reduce clearances. I was at a stove dealer last week and was explaining my set up and the guy there tells me that my clearances will have to be from the front of the brick since the brick will conduct the heat to the wall behind. The first guy told me that I could include the width of the brick as part of my clearance measurement. Who is right??? How is the set up that I have any different then the premade hearth pads that they sell and you throw down over a combustible floor? Any inspectors or professional installers out that can help? When I call the city they tell me whatever the installation instructions for the stove are is what they go by. The city inspector implied over the phone that the width of the brick could be included in the clearance to combustible distance. While this would greatly increase my stove options, I don't want to include it if it is not a safe thing to do. My families safety is my 1st priortiy. Any and all help would be greatly appreciated. Thanks again.

What I have is a corner hearth that was existing when we moved in last year. I would like to use this space as is without having to start all over. As you can see from the photo, the hearth is lined with brick, but the brick doesn't have an open air space behind it. Let me rephrase, I believe that it does have an air space as the brick is not tight to the wall, but the space is sealed at the top and bottom with mortar as would be required to reduce clearances. I was at a stove dealer last week and was explaining my set up and the guy there tells me that my clearances will have to be from the front of the brick since the brick will conduct the heat to the wall behind. The first guy told me that I could include the width of the brick as part of my clearance measurement. Who is right??? How is the set up that I have any different then the premade hearth pads that they sell and you throw down over a combustible floor? Any inspectors or professional installers out that can help? When I call the city they tell me whatever the installation instructions for the stove are is what they go by. The city inspector implied over the phone that the width of the brick could be included in the clearance to combustible distance. While this would greatly increase my stove options, I don't want to include it if it is not a safe thing to do. My families safety is my 1st priortiy. Any and all help would be greatly appreciated. Thanks again.

What I have is a corner hearth that was existing when we moved in last year. I would like to use this space as is without having to start all over. As you can see from the photo, the hearth is lined with brick, but the brick doesn't have an open air space behind it. Let me rephrase, I believe that it does have an air space as the brick is not tight to the wall, but the space is sealed at the top and bottom with mortar as would be required to reduce clearances. I was at a stove dealer last week and was explaining my set up and the guy there tells me that my clearances will have to be from the front of the brick since the brick will conduct the heat to the wall behind. The first guy told me that I could include the width of the brick as part of my clearance measurement. Who is right??? How is the set up that I have any different then the premade hearth pads that they sell and you throw down over a combustible floor? Any inspectors or professional installers out that can help? When I call the city they tell me whatever the installation instructions for the stove are is what they go by. The city inspector implied over the phone that the width of the brick could be included in the clearance to combustible distance. While this would greatly increase my stove options, I don't want to include it if it is not a safe thing to do. My families safety is my 1st priortiy. Any and all help would be greatly appreciated. Thanks again.

![DSCN1898[1].JPG](/talk/data/attachments/5/5066-c8648f64a3ecbd77f3a0509fc9898093.jpg)