I’ve been planning a wood boiler system, and following many discussions on and off for the past few years now. I have finally gathered together enough of the components to put some serious thought into bringing this plan to fruition. From observation I feel as if I’m entering into a battle of ideas that I’m poorly equipped to engage, but nonetheless need some direction.

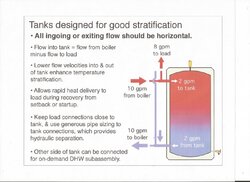

Having very little money to devote to this dream, I have collected what I have for next to nothing, and I simply want to figure out the best way to put it all together. To date I have a very well built single stage indoor wood boiler, a 500 gallon pressurized vertical water storage tank, a 40 gallon Amtrol indirect water heater, a 65kbtu air handler, and a well insulated garage with Pex tubing in the slab ready to go.

Primarily I need to know what to start looking for next, all items that I will need to be purchased, and none of them inexpensive, example: Loading unit versus separate pump and mixing valve, pumps versus zone vales, all of which could be answered by being directed to the correct piping diagram

Before I go any further and start dumping drawings and asking questions, is this the best place to do so? This site seems to be as comprehensive as anything out there, I’m not certain if I should tag along on an ongoing discussion or should I start fresh? Not only am I new to this site, but I’m new to this method exchanging ideas. Help!

Having very little money to devote to this dream, I have collected what I have for next to nothing, and I simply want to figure out the best way to put it all together. To date I have a very well built single stage indoor wood boiler, a 500 gallon pressurized vertical water storage tank, a 40 gallon Amtrol indirect water heater, a 65kbtu air handler, and a well insulated garage with Pex tubing in the slab ready to go.

Primarily I need to know what to start looking for next, all items that I will need to be purchased, and none of them inexpensive, example: Loading unit versus separate pump and mixing valve, pumps versus zone vales, all of which could be answered by being directed to the correct piping diagram

Before I go any further and start dumping drawings and asking questions, is this the best place to do so? This site seems to be as comprehensive as anything out there, I’m not certain if I should tag along on an ongoing discussion or should I start fresh? Not only am I new to this site, but I’m new to this method exchanging ideas. Help!