Over the summer I bought a cheap combustion gas analyizer. With the wood boiler now in full swing, I started trying to figure it out.

I got it connected, and running. I figured out the companion PC software and got the usb-serial link working.

I scanned a tag from the printer output on the device.

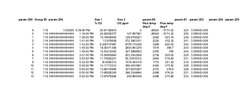

The spreadsheet was an import from a MDB table into excel.

If I look at the data with their tool, GAS1 is really %O2, GAS2 is CO. The other columns were harder to figure out. Parameter 60 was the flue gas temp, in deg c. , I added another column to compute *f.

Other data that their tool gives, take sample #13 for example CO2=7.1, eff net=68.1, eff=78.7, eff cond=68.1, loss net%=21.9, loss gross%=24.3, PI C/GIC=0.06, PI/GIG=0.3, CO ref ppm=518

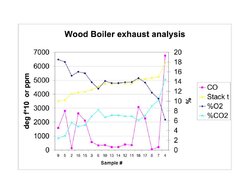

for the data set, the last 5 readings (8-13) were taken while the boiler was in the middle of a long burn. Sample 3 was taken with the door open(high air, high temp). sample 4 was taken with all air shut, high CO.

Can anybody help interpret these numbers ?

Is my wood boiler burning efficiently?

Thanks

I got it connected, and running. I figured out the companion PC software and got the usb-serial link working.

I scanned a tag from the printer output on the device.

The spreadsheet was an import from a MDB table into excel.

If I look at the data with their tool, GAS1 is really %O2, GAS2 is CO. The other columns were harder to figure out. Parameter 60 was the flue gas temp, in deg c. , I added another column to compute *f.

Other data that their tool gives, take sample #13 for example CO2=7.1, eff net=68.1, eff=78.7, eff cond=68.1, loss net%=21.9, loss gross%=24.3, PI C/GIC=0.06, PI/GIG=0.3, CO ref ppm=518

for the data set, the last 5 readings (8-13) were taken while the boiler was in the middle of a long burn. Sample 3 was taken with the door open(high air, high temp). sample 4 was taken with all air shut, high CO.

Can anybody help interpret these numbers ?

Is my wood boiler burning efficiently?

Thanks