Life is good...Solo 40 that didn't sell is set less controls, two 500 gal tanks from "Leaddog" on trailer front of garage

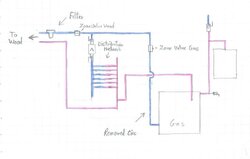

System prints posted for comments - "Boiler Room" and several of you are reading this posting

System in 12' x 24' boiler room, ground level behind garage, attached to two stories above - 2700 sq ft

After reviewing Simplest Pressurized Storage Sys and Cozy Heat design (thanks - nofossil & Dave) plus reading and learning off posting - I'm ready to get my design stamped "Ready For Construction"

1 - Tarm print calls for Aquestate Honeywell L4006B and looks like it is in/on flow line, is this sweated into system?

2 - H2O source = 1/2" copper, shut off valve, pressure temp gage, Extrol 60# expansion tank, Discal 551 air seperator

3 - Over heat loop = 1" copper, power fail zone valve, 40' 3/4" copper fin over heat loop in garage behind boiler room, shut off ball valve on return line. Power fail zone valve set up on elc on/off switch for heating options in garage, Molly likes her car warm in the am

4 - By pass loop = standard Tarm set up 1 1/4" flow and return stove taps to black pipe unions to sweated shut off ball valves, balance valve (not shown), TV-1 (stamped 72 deg?), Groundfos 3-speed pump.

5 - In floor heat = 1 1/14" copper, Groundfos 3-speed pump, Caleffi 6637F5A brass manifold 6 outlet. System to run 24-7 Oct-Apr "Comment Prints" show 1" but Caleffi is 1 1/4". Plan to only plumb for future system up to two shut off valves just above wood boiler 1 1/4" flow line. Parts bought so far = two rolls of 1/2" Pex. Anyone with thoughts please? Should system be moved to Gas boiler area? Thoughts are that it run compleatly seperate. Caleffi has 1 1/4" manifolds x 3/4" outlets - I'v got 1/2" Pex? Install temper valve?

6 - Filter/separator = if installed best location? Looking at Caleffi 5462

7 - Storage = two 500 gal propane tanks stacked working with 83" floor-ceiling, bottom tank to sit on 1" hard wood and welded in bracing (steel legs removed), two 12" pipe pups connecting tanks, additional welded in support, charging and withdrawing through 1 1/4" internal tank stand off pipes to 90 deg elbows to T's then 1 1/4" copper. Off top tank is relief valve, Extrol SX-60V = 32 gal volume (correct sixe ? using 3%=30 gal) considered top floor and set home made 30 gal tank vented - ??

Tanks under master bedroom - are there any noise issues during charging/discharging?

8 - Gas boiler = Burnham 7-22, series 2, 125,000 BTU/Hr Input-180,000 & Output 144,000 BTU's/Hr 35 years old. "Comment Prints" show 2" lines on boiler but they are 1 1/2" - copper with six 3/4" zones, no zone valves tho. Thermostat calls for heat, burner ignites and pump comes on. All 6 zones are balanced manually with each 3/4" ball valves. Any one know how long this boiler will last? I'm thinking 2-3 years max - then tankless with new 3/4" zone valves - empty nest.

9 - Wood to Gas hook up = Options to tie in Wood 1 1/4" into 1 1/2" Gas - on top of zones or below? On top is easy, just sweat in 1 1/4" reducer on top of each 1 1/2" stack, hot to hot, return to return and switch directions of pump (is switching pump directions possible?) If I have to get below 3/4" zones on 1 1/2" stacks it will require removing both 2" black pipe flow and return 90 deg elbows from boiler and install T's - concerned with removing 90 Deg elbows 35yr old boiler?? Is the single speed Groundfos pump on Gas boiler enough? - 23' of 1 1/4" run length distance from storage tank pick up to gas boiler

10 - Design of elc control system is beyond me - anything need sweated in? please enough help that a plumber friend and I can follow

11 - Don't understand how/if the single 1 1/4" flow line is enough to supply in floor and charge tanks/heat home. Solo 40 has two flow and return taps - should I be using second tap for anything - say separate lines to charge storage tank?

thanks - jim

System prints posted for comments - "Boiler Room" and several of you are reading this posting

System in 12' x 24' boiler room, ground level behind garage, attached to two stories above - 2700 sq ft

After reviewing Simplest Pressurized Storage Sys and Cozy Heat design (thanks - nofossil & Dave) plus reading and learning off posting - I'm ready to get my design stamped "Ready For Construction"

1 - Tarm print calls for Aquestate Honeywell L4006B and looks like it is in/on flow line, is this sweated into system?

2 - H2O source = 1/2" copper, shut off valve, pressure temp gage, Extrol 60# expansion tank, Discal 551 air seperator

3 - Over heat loop = 1" copper, power fail zone valve, 40' 3/4" copper fin over heat loop in garage behind boiler room, shut off ball valve on return line. Power fail zone valve set up on elc on/off switch for heating options in garage, Molly likes her car warm in the am

4 - By pass loop = standard Tarm set up 1 1/4" flow and return stove taps to black pipe unions to sweated shut off ball valves, balance valve (not shown), TV-1 (stamped 72 deg?), Groundfos 3-speed pump.

5 - In floor heat = 1 1/14" copper, Groundfos 3-speed pump, Caleffi 6637F5A brass manifold 6 outlet. System to run 24-7 Oct-Apr "Comment Prints" show 1" but Caleffi is 1 1/4". Plan to only plumb for future system up to two shut off valves just above wood boiler 1 1/4" flow line. Parts bought so far = two rolls of 1/2" Pex. Anyone with thoughts please? Should system be moved to Gas boiler area? Thoughts are that it run compleatly seperate. Caleffi has 1 1/4" manifolds x 3/4" outlets - I'v got 1/2" Pex? Install temper valve?

6 - Filter/separator = if installed best location? Looking at Caleffi 5462

7 - Storage = two 500 gal propane tanks stacked working with 83" floor-ceiling, bottom tank to sit on 1" hard wood and welded in bracing (steel legs removed), two 12" pipe pups connecting tanks, additional welded in support, charging and withdrawing through 1 1/4" internal tank stand off pipes to 90 deg elbows to T's then 1 1/4" copper. Off top tank is relief valve, Extrol SX-60V = 32 gal volume (correct sixe ? using 3%=30 gal) considered top floor and set home made 30 gal tank vented - ??

Tanks under master bedroom - are there any noise issues during charging/discharging?

8 - Gas boiler = Burnham 7-22, series 2, 125,000 BTU/Hr Input-180,000 & Output 144,000 BTU's/Hr 35 years old. "Comment Prints" show 2" lines on boiler but they are 1 1/2" - copper with six 3/4" zones, no zone valves tho. Thermostat calls for heat, burner ignites and pump comes on. All 6 zones are balanced manually with each 3/4" ball valves. Any one know how long this boiler will last? I'm thinking 2-3 years max - then tankless with new 3/4" zone valves - empty nest.

9 - Wood to Gas hook up = Options to tie in Wood 1 1/4" into 1 1/2" Gas - on top of zones or below? On top is easy, just sweat in 1 1/4" reducer on top of each 1 1/2" stack, hot to hot, return to return and switch directions of pump (is switching pump directions possible?) If I have to get below 3/4" zones on 1 1/2" stacks it will require removing both 2" black pipe flow and return 90 deg elbows from boiler and install T's - concerned with removing 90 Deg elbows 35yr old boiler?? Is the single speed Groundfos pump on Gas boiler enough? - 23' of 1 1/4" run length distance from storage tank pick up to gas boiler

10 - Design of elc control system is beyond me - anything need sweated in? please enough help that a plumber friend and I can follow

11 - Don't understand how/if the single 1 1/4" flow line is enough to supply in floor and charge tanks/heat home. Solo 40 has two flow and return taps - should I be using second tap for anything - say separate lines to charge storage tank?

thanks - jim