Hello all,

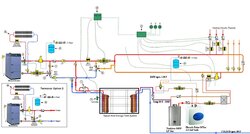

I am by no means a hydronic expert. I have come up with a design for a hydronic/DHW with a wood boiler, thermal storage, and propane backup heat using a tankless DHW heater. Oh also I have added a small point of use electric hot water heater and a circulatory to provide instant DHW. I got some of the design from a Tarm Solo diagram I found on the internet and I got the other part by looking at the Navien System. I'm interested in getting feedback on the diagram. Please point out any parts of the system that would not work or any improvements. As you can see I also need some help with controls. Oh and please keep the lafter to a minimum

I am by no means a hydronic expert. I have come up with a design for a hydronic/DHW with a wood boiler, thermal storage, and propane backup heat using a tankless DHW heater. Oh also I have added a small point of use electric hot water heater and a circulatory to provide instant DHW. I got some of the design from a Tarm Solo diagram I found on the internet and I got the other part by looking at the Navien System. I'm interested in getting feedback on the diagram. Please point out any parts of the system that would not work or any improvements. As you can see I also need some help with controls. Oh and please keep the lafter to a minimum