Hi everyone. I just purchased a Harman SF-160 wood/coal boiler to supplement the oil boiler (http://www.harmanstoves.com/products/details.asp?cat=central-heating&prd=boilers&f=BLRSF160). The Wood Boiler will be placed into my attached garage, about 25 feet away from my oil boiler located in the basement. I'm having trouble figuring out the best method for connecting the two boilers because my goal is to keep my oil boiler 'hot' since my oil boiler has the domestic hot water coil. Otherwise, I would just bypass the oil boiler altogether like many of the diagrams show on this forum.

The directions (posted below) instruct me to run a pipe from the oil boiler return to the wood boiler return and then run another pipe from the wood boiler supply to the oil boiler supply. This should create a constant loop between the two boilers keeping the oil boiler hot for the three heating zones plus the domestic hot water.

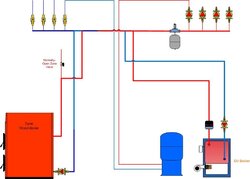

This is option #2 that I've posted a picture of below.

However, will it be better to run a pipe from the wood boiler supply to the oil boiler return and then run another pipe from the wood boiler return to the oil boiler supply? With this option, the full amount of hot water from the wood boiler will always run through the entire boiler. With option #2, SOME of the heated water from the wood boiler will bypass the oil boiler. I'm concerned that this will prevent the domestic coil in the oil boiler from staying heated during a long shower on a cold day (when all zone circulates are on).

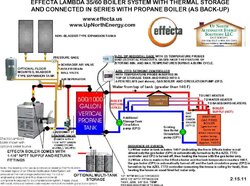

Here are some diagrams:

From Boiler Manual:

Option #1:

Option #2:

The directions (posted below) instruct me to run a pipe from the oil boiler return to the wood boiler return and then run another pipe from the wood boiler supply to the oil boiler supply. This should create a constant loop between the two boilers keeping the oil boiler hot for the three heating zones plus the domestic hot water.

This is option #2 that I've posted a picture of below.

However, will it be better to run a pipe from the wood boiler supply to the oil boiler return and then run another pipe from the wood boiler return to the oil boiler supply? With this option, the full amount of hot water from the wood boiler will always run through the entire boiler. With option #2, SOME of the heated water from the wood boiler will bypass the oil boiler. I'm concerned that this will prevent the domestic coil in the oil boiler from staying heated during a long shower on a cold day (when all zone circulates are on).

Here are some diagrams:

From Boiler Manual:

Option #1:

Option #2:

.

.