sgschwend said:

So, because the bottom did not drop that far compared to the other probes you think it is mixing? If the bottom had dropped quite a bit more then you would say the tank needs more insulation?

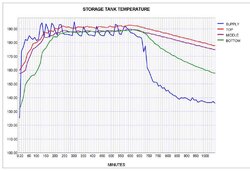

I think that my 500 gallon tank: the top drops about 10 degrees in that amount of time while the bottom drops 40-50.

Well, lets split that in half...

1. NoFo, and some of our other people have said that a well insulated tank will drop 1-2°F / day w/ no thermal draw on it. This doesn't seem unreasonable to me as a goal, as per the descriptions I've seen it doesn't take huge amounts of insulation to get to that point, but going for more than that gets expensive in terms of the amount of thermal efficiency gained... Even assuming that the cost per inch of added insulation is a constant, if each additional inch cuts the thermal loss by 50%, the first few inches cut a lot of loss, but at the 1-2°F / day level, the gains are pretty small...

OTOH, if the tank was not well insulated, then you'd see a drop across the entire tank, though the hot sections would cool faster than the bottom since radiation is a function of ΔT. Still should be a fairly steady drop...

It is possible that lack of insulation is part of the explanation for Jim's temp drop - I seem to recall him saying he leaves part of his tank bare so that it can act as a shop radiator...

2. If one had the hypothetical "perfect" tank with complete stratification, then the tank temperature would be low (minimum usable temp or close to it) at the bottom, and at some point you would have a narrow thermocline separating the hot and cold layers, with hot on top, with very little change in temp within the hot and cold layers. As the heat was used, the thermocline would slowly move up the tank till it reached the top... If you had a series of sensors (say 10, instead of just three) you would see a "stair step" effect as each sensor would be reading at the hot temp until the thermocline reached the sensor, at which point it would drop steeply to the lower temp. W/ only three sensors, I'd expect to see the same thing, just not as dramatically. The narrower the thermocline, the more abruptly the temperature would drop.

OTOH, if there is a lot of mixing, I'd expect to see less difference between the sensors.

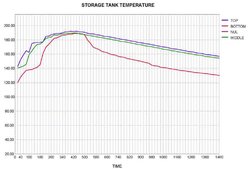

Looking at Jim's chart, I see a high peak with all three sensors within a degree or so of each other at around 420-450. All three sensors start to drop at the same rate till around 500. Shortly after that the top and bottom sensors continue to drop in unison, while the bottom sensor drops till it has about a 20°F ΔT by around 660, with most of the drop happening from 500-580. After that point, all three sensors drop at the same rate until we hit the end of the chart.

I see two possible explanations - either there is enough mixing in the upper portions of the tank to drop both sensors at the same rate, or we have good stratification, w/o pulling enough heat out of the tank to make the middle sensor see the thermocline and start dropping, but the entire tank is going down because it isn't insulated well... (If we had more sensors in between the 3 that are already there it might be easier to tell which it is...)

Gooserider