Nofossil

Moderator Emeritus

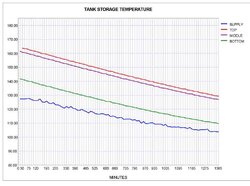

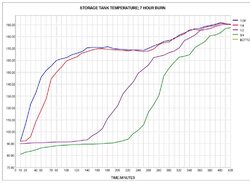

This is pretty interesting. I have an open tank with an undersized HX coil in it, so I end up not getting much stratification.

I've included a chart. but it's more interesting to click this link to get a 'live' flash chart - I finally got it working to my satisfaction.

I'd love to get the stratification values that I see in your charts. I do find it interesting that the tank bottom temp gets so low so quickly.

I've included a chart. but it's more interesting to click this link to get a 'live' flash chart - I finally got it working to my satisfaction.

I'd love to get the stratification values that I see in your charts. I do find it interesting that the tank bottom temp gets so low so quickly.