Digital LED temp readout and alarm installed

- Thread starter woodmiser

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

WES999

Minister of Fire

Just checked the manual on mine, says SYL-1512A1, no alarm mute button.

Looks like I have the old one and you have the new one.

Looks like I have the old one and you have the new one.

mattjmcl

Member

Treacherous said:Even mine on outy=2 (default) appears to work as well. I am going to change over to 3 since woodmiser had good luck with that setting. Auber is sending out a replacement buzzer. The 12volt version was accidentally sent to me instead of the 120V version. On mine the J1 output will activate at alarm, mute with > and then reactivate J1 again once temp has gone below AL1 and then back above AH1

That's funny, they did the same to me. I thought for sure I messed up on my order. But when I looked, it was their wrong pick.

Treacherous

Minister of Fire

So far Auber customer service has been good. I emailed them about the error last night and they emailed me this morning that they are shipping one out.

raybonz

Minister of Fire

Have you considered using an on-delay timer instead of a relay? This would allow the temp to trigger the temp control output act as a debounce feature for instance if you used a time delay of 1 minute it would not trigger the alarm until the output from the temp control went high for 1 solid minute and this would reduce nuisance alarms.. If you really want to take it to the next level buy a $135.00 PLC such as this one http://tinyurl.com/cp4j5c3 .. The programming software is free as long as your program is small and allows flexibility to change things easily once the I/O is wired.. Overall I am impressed with what you've guys have done so far..

Ray

Ray

mattjmcl

Member

I sent an email to them the other night. Glad to hear they've gotten back to you and are sending out a replacement.

Treacherous

Minister of Fire

I probably won't mess with the direct fan control option until my Lopi electrical component warranty expires next year.

Do you think it will be fairly easy to override the rheostat for full speed fan control that activates during an over-fire scenario? I still want to be able to use the variable fan control as well.

Do you think it will be fairly easy to override the rheostat for full speed fan control that activates during an over-fire scenario? I still want to be able to use the variable fan control as well.

Treacherous said:ajreid said:I've been thinking about doing this for a while. Tonight i finally purchased the equipment to do it. Possibly next weekend Ill have it operational. I'm going to try to have my blower on the stove turn on as well as the alarm on overheat.

Even thought about a fire alarm horn strobe. Lot of ideas nothing definite.

Good idea on turning on with an overheat.

I ordered up items the other day as well.

Treacherous said:I probably won't mess with the direct fan control option until my Lopi electrical component warranty expires next year.

Do you think it will be fairly easy to override the rheostat for full speed fan control that activates during an over-fire scenario? I still want to be able to use the variable fan control as well.

Treacherous said:ajreid said:I've been thinking about doing this for a while. Tonight i finally purchased the equipment to do it. Possibly next weekend Ill have it operational. I'm going to try to have my blower on the stove turn on as well as the alarm on overheat.

Even thought about a fire alarm horn strobe. Lot of ideas nothing definite.

Good idea on turning on with an overheat.

I ordered up items the other day as well.

I haven't taken the fan off to look at it yet but that would be a good way to have it set up.

WES999

Minister of Fire

Have you considered using an on-delay timer instead of a relay? This would allow the temp to trigger the temp control output act as a debounce feature for instance if you used a time delay of 1 minute it would not trigger the alarm until the output from the temp control went high for 1 solid minute and this would reduce nuisance alarms.. If you really want to take it to the next level buy a $135.00 PLC such as this one http://tinyurl.com/cp4j5c3 .. The programming software is free as long as your program is small and allows flexibility to change things easily once the I/O is wired.. Overall I am impressed with what you’ve guys have done so far..

I don't think a time delay would be the best approach. On a cold start with dry kindling you might be surprised how fast flue temp can rise, when the alarm goes off you really need to turn down the air right away. Waiting for a minute, the flue temp may increase by several hundred degrees. Nuance alarms really are not a problem. You just need to acknowledge the alarm and turn it off while you close the air and let the temp go down.

Your right the Automation Direct PLC are nice, I have worked with them in the past. I sold one on Ebay some years ago, I am wishing I would have kept it. It would have been just the the ticket for automating the air control.

Do you think it will be fairly easy to override the rheostat for full speed fan control that activates during an over-fire scenario? I still want to be able to use the variable fan control as well.

I don't think it would be too difficult. On my stove I have only have a switch for hi and low speed.

I wired my stove top controller to turn the fan on hi at 675 °F . Otherwise generally don't use the fan.

On my stove it was pretty simple to wire.

Treacherous

Minister of Fire

I got the correct 120V buzzer earlier in the week.

How are most mounting that? I was thinking of making some kind of bracket but short term might just just a zip tie or use some good old black electrical tape.

How are most mounting that? I was thinking of making some kind of bracket but short term might just just a zip tie or use some good old black electrical tape.

Treacherous

Minister of Fire

outy=2 seems to work fine. I might just leave it there. Maybe I will need to change if I add an additional relay to drive the high speed fan setting on the rheostat?

Treacherous said:Even mine on outy=2 (default) appears to work as well. I am going to change over to 3 since woodmiser had good luck with that setting. Auber is sending out a replacement buzzer. The 12volt version was accidentally sent to me instead of the 120V version. On mine the J1 output will activate at alarm, mute with > and then reactivate J1 again once temp has gone below AL1 and then back above AH1

mattjmcl

Member

Treacherous said:I got the correct 120V buzzer earlier in the week.

How are most mounting that? I was thinking of making some kind of bracket but short term might just just a zip tie or use some good old black electrical tape.

I just got my right buzzer today! Hooked it up and tried it... Light flashes, but no sound?!? Any ideas?!?

Treacherous

Minister of Fire

Sounds like it is defective. It either works or not. I'd email this address---> [email protected]

They were quick to respond after I let them them know that I received an incorrect buzzer.

They were quick to respond after I let them them know that I received an incorrect buzzer.

mattjmcl

Member

Thanks! I was going to send them something. But thought I'd see if I did something wrong through here first. ;-)

Treacherous

Minister of Fire

My buzzer is wired up as follows:

• 2 wired to 4

• 5 wired to buzzer

• other wire from buzzer wired to 1

• 2 wired to 4

• 5 wired to buzzer

• other wire from buzzer wired to 1

mattjmcl

Member

Treacherous

Minister of Fire

Looks like my thermocouple is actually reading low by about 75 degrees. Anyone tweaked theirs yet?

Treacherous said:You might be able to tweak the accuracy with section 4.2 in the instructions. So far mine seems accurate on the gas fireplace. Unfortunately my IR is back at cabin so won't know for sure until I get back over there. I've never played with these PIDs before so a little curve for me. They do seem to offer a lot of options in a small package though.

WES999

Minister of Fire

Why do you think it is low? Are you checking it with an IR thermometer?

It may be that the magnetic thermocouple just needs to catch up with the stove top.

I have checked mine with a hand held surface probe and another temp monitor and it is always pretty close.

It may be that the magnetic thermocouple just needs to catch up with the stove top.

I have checked mine with a hand held surface probe and another temp monitor and it is always pretty close.

Treacherous

Minister of Fire

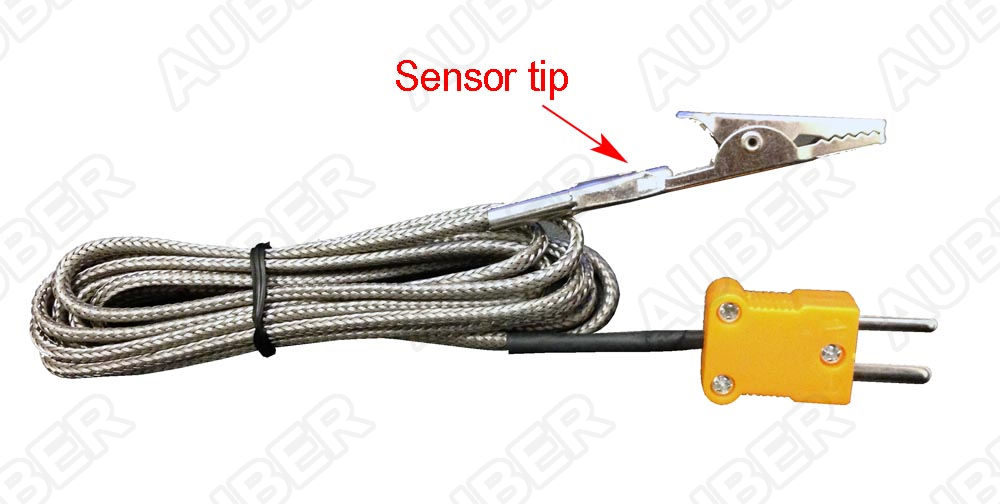

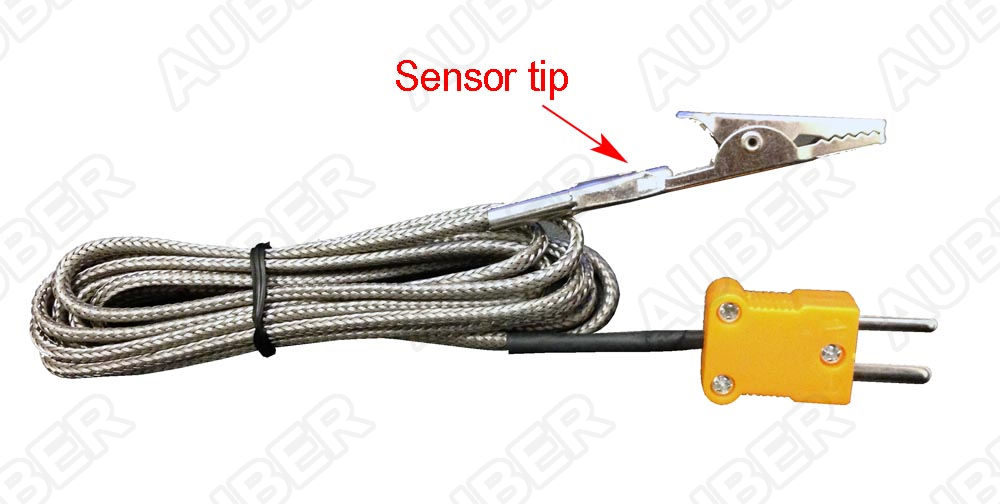

Yeah... I am checking with my IR thermometer. This has been the first chance I have gotten to test on the wood stove. The other test was on my home's gas fireplace but I didn't have the IR gun there to test with. I've been burning since about 9AM today. It's been pretty consistent and is touching stove as well as it can. It is directly contacting it on the head of the probe.

Treacherous

Minister of Fire

Which thermocouple are you using? Yours looks different and seems like it would make a better contact with a flat surface. I think you posted a parts list. I'll look for that as well.

WES999 said:Why do you think it is low? Are you checking it with an IR thermometer?

It may be that the magnetic thermocouple just needs to catch up with the stove top.

I have checked mine with a hand held surface probe and another temp monitor and it is always pretty close.

Treacherous

Minister of Fire

The thermocouple I am using comes in from the top of the magnet so I can protect the wiring since someone said there was a 500 degree limit. Is the wiring on yours protected above 500 degrees? My current reading is fairly accurate I just need to tweak the display somehow (if possible) to read the true temperature of 75 degrees higher.

WES999

Minister of Fire

I am using this one #WTCK-160 from here: http://www.ppe.com/11cat/0657.pdf

My wire touches the very edge of the stove, does not seem to be a problem.

If you are worried about the heat the same company has hi temp fiberglass sleeving, they say is is good to 1000 °F look at # ST-2. http://www.ppe.com/11cat/0744.pdf

If you are sure you controller is reading low you can program an input offset.

It is PSb on the config menu.

My wire touches the very edge of the stove, does not seem to be a problem.

If you are worried about the heat the same company has hi temp fiberglass sleeving, they say is is good to 1000 °F look at # ST-2. http://www.ppe.com/11cat/0744.pdf

If you are sure you controller is reading low you can program an input offset.

It is PSb on the config menu.

Treacherous said:The thermocouple I am using comes in from the top of the magnet so I can protect the wiring since someone said there was a 500 degree limit. Is the wiring on yours protected above 500 degrees? My current reading is fairly accurate I just need to tweak the display somehow (if possible) to read the true temperature of 75 degrees higher.

Keep in mind that as soon as you get away from the stove, even a inch, temp drops dramatically so say your stove top metal is 600°... the air an inch above is much cooler. Your thermocouple wire should be fine. Not only that, my wire is in the path of the blower air.

Treacherous

Minister of Fire

WES999 said:If you are sure you controller is reading low you can program an input offset.

It is PSb on the config menu.

Thanks!

The PSb tweak did the trick. Now it is accurate.

Treacherous

Minister of Fire

I got paranoid and added a little extra stack.

woodmiser said:Treacherous said:The thermocouple I am using comes in from the top of the magnet so I can protect the wiring since someone said there was a 500 degree limit. Is the wiring on yours protected above 500 degrees? My current reading is fairly accurate I just need to tweak the display somehow (if possible) to read the true temperature of 75 degrees higher.

Keep in mind that as soon as you get away from the stove, even a inch, temp drops dramatically so say your stove top metal is 600°... the air an inch above is much cooler. Your thermocouple wire should be fine. Not only that, my wire is in the path of the blower air.

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 724

- Replies

- 1

- Views

- 986

- Replies

- 4

- Views

- 607

- Replies

- 4

- Views

- 740