d-bone20917 said:

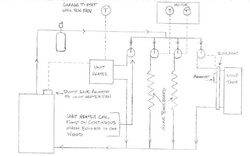

I apologize if any of these are stupid questions, but this is a first for me. I was under the impression that you needed continuous circulation for a wood boiler because it doesn’t kick on and off like a gas or oil boiler. The boiler has a fuel oil back-up also which we would use if we go out of town for some reason. In this instance I will also need the circ pump on the unit heater tied to a garage thermostat. Obviously I wouldn’t want constant circulation if I’m burning oil. I’m not concerned about the garage freezing. It is an attached garage and very well insulated. I would plan to leave the thermostat on 55 or so all the time and turn it up when I plan to work out there, which is all the time when I’m not at my real job. I currently heat the garage with a woodstove, which I plan to remove.

Would I be better off to have constant circulation through the sidearm and have the unit heater circ on a thermostat? Then if we go away and switch to oil I could just shut off that pump. No reason to have hot water if we aren’t home anyway.

Thanks for the feedback.

If you are trying to learn, there aren't stupid questions... You may or may not need constant circulation with a wood burner, but yes, you probably will need more than a fossil burner. That you have a backup oil burner won't change your plumbing all that much, although it will have an impact on your control strategy.

Now when you are burning, the fire will be producing heat, and in order to stay comfortable on "design days" (the coldest weather you plan for) and because of the cyclical nature of a wood fire, most of the time you will be capable of producing more heat than you have a demand for from your heating loads... There are essentially three or four things you can normally do to deal with the excess heating potential...

1. Constantly dump heat into a zone, regardless of whether it is calling for it or not - can lead to uncomfortable overheating, and in the case of a DHW tank, the amount of heat it can accept before overheating is fairly small. In any rate this is in effect "throwing away" those BTU's as they won't be available for use to satisfy a later demand.

2. Restrict the air flow into the boiler, and run it at less than full output - This is less efficient, and will tend to lead to more smoke and creosote as you can't get clean combustion withot enough air. Again, throwing BTU's away, except now you are spreading them around the neighborhood as excess smoke, instead of trying to dissipate them as excess heat...

3. Shut the boiler down most of the way so that it "idles" with minimal combustion, except when there is a heat call, and you come off idle to answer it. This is more efficient than option two, but you will still get a certain amount of air starved combustion smoke, plus you will have some excess smoke each time you have to switch the fire from idle to full burn - so it still wastes heat, but less so... You might still need some level of circulation to keep the idling boiler from overheating, but probably much less so.

4. Run the boiler flat out, and dump all the excess heat produced during the burn into a storage tank, where they can be saved for use at a later point, after the fire has burned out... This way the storage tank acts as a "flywheel" to even out the heat production and only give your heating system as many BTU's at any point as it "needs" - This gives you the best of both worlds, a boiler that is burning as cleanly and efficiently as it is capable of, and not wasting any BTU's that are produced in exess of the demand. As a bonus, the storage tank also gives you a much longer effective "burn time" as it lets you increase the time between boiler tending sessions....

In terms of the control strategy, it really doesn't matter whether the boiler uses an internal backup fossil burner, or if you had a seperate fossil boiler, as you would do about the same either way, namely have the system plumbed so that the fossil boiler only supplied the actual heating demand loads, and did NOT attempt to heat the storage tank...

The other issue that needs to be addressed, is the question of what do you do when "chit happens" and you have a potential overheating scenario - typically some sort of pump or plumbing failure that prevents normal circulation, often due to a power failure... This is where you will see mention of "dump zones" which are either existing heating zones set up so they can at least somewhat flow with gravity, or an extra "gravity loop" that is only used in this sort of emergency - when you have to throw BTU's away in order to prevent worse things from happening...

Hate to sound so insistent on the storage, but it really does seem to be the "magic key" to making a wood setup work efficiently, whether it is a conventional boiler or a gasifier.

Gooserider