-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

E

elkimmeg

Guest

Definitely a PITA Thought it would take an hour but I had to make a trip onto the roof to pull the Chimney up and again to lower it

Yeah it was raining actually sleeting But I was able to get it done almost 3 hours due to a trip back home to get the saber saw.

You know not a bad stove Unbelieaveable for $288 I Im going to print the pictures and provide the flame testing report of hardibacker board and bring toem to the inspector also photo copy the NFPA reduced enclosure specs

To answer goose about one missing screw, I ran out of black 3" drywall screws and used a galvanized couple that does not show up in the photo

Irs up to the homeowner to paint it after inspection Now the stove top only neeeds 22 "" of clearance above it with this type of non combustiable enclosure clearance distance can be reduced 66%

Yeah it was raining actually sleeting But I was able to get it done almost 3 hours due to a trip back home to get the saber saw.

You know not a bad stove Unbelieaveable for $288 I Im going to print the pictures and provide the flame testing report of hardibacker board and bring toem to the inspector also photo copy the NFPA reduced enclosure specs

To answer goose about one missing screw, I ran out of black 3" drywall screws and used a galvanized couple that does not show up in the photo

Irs up to the homeowner to paint it after inspection Now the stove top only neeeds 22 "" of clearance above it with this type of non combustiable enclosure clearance distance can be reduced 66%

GVA

Minister of Fire

My hats off to you Elk for really going all the way. The family must be thrilled considering the weather you've been having. Well done!

Gooserider

Mod Emeritus

Sounds great, looks like it should solve all the questions. Glad everything has hopefully been worked out.

Gooserider

Gooserider

Harley

Minister of Fire

E

elkimmeg

Guest

what I did was use a 6' level and marked out the stove footprint on the ceiling Fron there I cut a 54" strapping piece and angled it from the stove,Marked out that foot print. At that piont I could have cut the hardibacked board from the 60 to 38" Width I could have cut it to 32" from 36" I then figured it was better to include the complete ceiling adapter and make no length and width cuts.

I also had to locate the strapping to attach the board. I offcentered it a bit to include extra protection of the single wall pipe and the actuall ceiling connection and adapter boot. I must say Hardibacker board is much easier to work with that cement board lighter and cuts better

Thermal Values (ASTM C177)

1/4" HardieBacker and 1/4" HardieBacker EZ Grid® cement board Thermal Conductivity: k-value 7.80 Btu/ft2 x h x °F

1/2" HardieBacker cement board Thermal Conductivity: k-value 20.07 Btu/hr-ft2 - °F

1/4" HardieBacker and 1/4" HardieBacker EZ Grid® cement board Thermal Resistance: R-value 0.13 ft2 x h x °F/Btu

1/2" HardieBacker cement board Thermal Resistance: R-value 0.05 hr-ft2 - °F/Btu

Non-Combustibility

When tested in accordance with ASTM Method E-136, HardieBacker cement board is recognized as a non-combustible building material in NER-405.

Surface Burning Characteristics

When tested in accordance with ASTM method E-84: Flame Spread – 0, Fuel Contributed – 0, Smoke Developed – 5.

Fire Rated Assemblies

Hardibacker cement board may be used as a component in one-hour fire-resistive wall construction; consult NER-405 and Intertek-ETLSemko website listings for recognized assemblies, or contact James Hardie’s Technical Services at 1-800-9HARDIE (1-800-942-7343).

I also had to locate the strapping to attach the board. I offcentered it a bit to include extra protection of the single wall pipe and the actuall ceiling connection and adapter boot. I must say Hardibacker board is much easier to work with that cement board lighter and cuts better

Thermal Values (ASTM C177)

1/4" HardieBacker and 1/4" HardieBacker EZ Grid® cement board Thermal Conductivity: k-value 7.80 Btu/ft2 x h x °F

1/2" HardieBacker cement board Thermal Conductivity: k-value 20.07 Btu/hr-ft2 - °F

1/4" HardieBacker and 1/4" HardieBacker EZ Grid® cement board Thermal Resistance: R-value 0.13 ft2 x h x °F/Btu

1/2" HardieBacker cement board Thermal Resistance: R-value 0.05 hr-ft2 - °F/Btu

Non-Combustibility

When tested in accordance with ASTM Method E-136, HardieBacker cement board is recognized as a non-combustible building material in NER-405.

Surface Burning Characteristics

When tested in accordance with ASTM method E-84: Flame Spread – 0, Fuel Contributed – 0, Smoke Developed – 5.

Fire Rated Assemblies

Hardibacker cement board may be used as a component in one-hour fire-resistive wall construction; consult NER-405 and Intertek-ETLSemko website listings for recognized assemblies, or contact James Hardie’s Technical Services at 1-800-9HARDIE (1-800-942-7343).

Xena

Minister of Fire

You're a good egg Elk. I'm sure the family

is very appreciative of all the hard work

you've done for them. They are lucky as heck!

is very appreciative of all the hard work

you've done for them. They are lucky as heck!

webbie

Seasoned Moderator

My guess is that this cement board would have done the job without being spaced - in other words, just the K or R value. But it's tough to prove it unless you get in touch with the manufacturers or provide solid numbers and formulas.

Maybe one of the engineers here can work out the potential reduction for that specific K value when it is NOT spaced. My completely guesswork idea would be about a 20% reduction. Brick is 33% (I think) according to NFPA even when tight against the wall.

One concern with wall protection is always how far on the sides of the "shadow" of the stove it should go. NFPA specifies this for generic (I think it is 18" past all sides of the shadow)......but in a case like this (Elks), common sense would dictate that you only have to protect far enough until you hit the 52" on a diagonal.

Is that what you used, Elk, as the sizing for the ceiling shield?

Maybe one of the engineers here can work out the potential reduction for that specific K value when it is NOT spaced. My completely guesswork idea would be about a 20% reduction. Brick is 33% (I think) according to NFPA even when tight against the wall.

One concern with wall protection is always how far on the sides of the "shadow" of the stove it should go. NFPA specifies this for generic (I think it is 18" past all sides of the shadow)......but in a case like this (Elks), common sense would dictate that you only have to protect far enough until you hit the 52" on a diagonal.

Is that what you used, Elk, as the sizing for the ceiling shield?

scotty

Member

I just went over this same thing with the local inspectors. They do not accept Hardibacker board or any other thermal barrier as automatically decreasing a stove's required "distance to combustibles". The only way a decrease is accepted is if the stove manufacturer's installation manual specifically describes the method of constructing the thermal barrier and also states the resulting decrease in distance. Just meeting National Fire Codes is nice, but not sufficient.

Mountain Stove Guy

Mountain Stove Guy

Xena

Minister of Fire

Scotty I think Elk did end up using it and it did pass,

look at this thread -- https://www.hearth.com/econtent/index.php/forums/viewthread/7564/

https://www.hearth.com/econtent/index.php/forums/viewthread/7564/

See Elk, I pay attention too. :cheese: ;-)

look at this thread --

https://www.hearth.com/econtent/index.php/forums/viewthread/7564/

https://www.hearth.com/econtent/index.php/forums/viewthread/7564/See Elk, I pay attention too. :cheese: ;-)

E

elkimmeg

Guest

Zeta fine riding and fishing weather.

What can I say, then garages can not be attached to homes because manufactures did not sppecify One hour fire code sheet rock

Evidently this guy has not read the codes because the practice of reduced clearances in not just in the NFPA but in the international Mechanical Codes, the International Gas Codes

Also found is the oil burner codes. No MANSORY fireplaces may be built because the manufacturer did not specify construction /installation

I think your inspector does not know the code, therefore does not understand it so rather than make any effort to be educated, he is limited to what is in a booklet from manufactures

Most manufactures have testing labs with movable walls and NFPA reduced enclosures to test stoves clearances

What can I say, then garages can not be attached to homes because manufactures did not sppecify One hour fire code sheet rock

Evidently this guy has not read the codes because the practice of reduced clearances in not just in the NFPA but in the international Mechanical Codes, the International Gas Codes

Also found is the oil burner codes. No MANSORY fireplaces may be built because the manufacturer did not specify construction /installation

I think your inspector does not know the code, therefore does not understand it so rather than make any effort to be educated, he is limited to what is in a booklet from manufactures

Most manufactures have testing labs with movable walls and NFPA reduced enclosures to test stoves clearances

webbie

Seasoned Moderator

scotty said:I just went over this same thing with the local inspectors. They do not accept Hardibacker board or any other thermal barrier as automatically decreasing a stove's required "distance to combustibles". The only way a decrease is accepted is if the stove manufacturer's installation manual specifically describes the method of constructing the thermal barrier and also states the resulting decrease in distance. Just meeting National Fire Codes is nice, but not sufficient.

Mountain Stove Guy

I hear ya.....

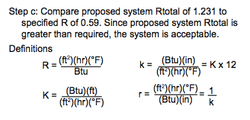

Some manuals, such as VC (example) have the entire complicated formula enclosed, but you have to be a rocket scientist to figure the dang thing out. That would be cool, though, to bring in the calcs to the local inspector and have him try to decipher it.

See enclosed.....

This is where it becomes important for inspectors to be able to make judgments in the field. Elk will probably tell you that there is no house standing today where every detail meets the strict code - nail length, nail angle, distance between nails, exact condition of the framing wood, etc. etc. - But he knows when there is leeway and when there is not.

When I have some spare time I'll try to come up with the exact reduction that one layer of cement board provides.....expressed as a percentage. Maybe someday I'll try to put together an online calculator to work with some of this stuff.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 23

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 11

- Views

- 1K

- Replies

- 10

- Views

- 1K