I don't recall seeing much if anything on draft fan speed control, but if a good thread exists, please let me know. I have a manual motor speed control connected to my draft fan. I use it to slow the fan down only when flue temps get much higher than I want, usually when the temp starts to get close to 500F. My boiler works really well with flue temps around 450-475F.

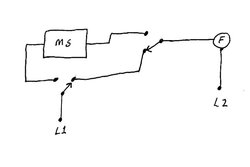

I located a K-type temperature controller for $25, and maybe someone knows one that is even less expensive. What I thought is to connect the motor speed control on a "slow" setting so that when flue temp reaches the desired maximum temp, the fan slows down, and then speeds up again as the flue temp drops. A DPST relay would do this nicely. The coil could be 24vac or line voltage, whatever is desired, and would be controlled by the temperature controller.

Are there better ways to provide automatic draft fan speed control?

EDIT: Relay should be DPDT.

I located a K-type temperature controller for $25, and maybe someone knows one that is even less expensive. What I thought is to connect the motor speed control on a "slow" setting so that when flue temp reaches the desired maximum temp, the fan slows down, and then speeds up again as the flue temp drops. A DPST relay would do this nicely. The coil could be 24vac or line voltage, whatever is desired, and would be controlled by the temperature controller.

Are there better ways to provide automatic draft fan speed control?

EDIT: Relay should be DPDT.