The bottom line is that if an indoor drying method like this 'works' for you, then you are free to do it. Period.

As a group, we have in the past been unable to agree on an outside seasoning time suggestion, b/c of all the variables of climate, split size etc.

The gen'l guideline 'one year, except dense species which get two' is great (conservative) advice for folks who have the ability to put up a year or two of wood--a

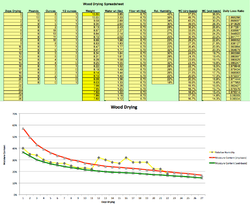

lot of us don't. In reality, with outdoor drying, YMMV. The nature of wood drying has this diminishing returns (decelerating) characteristic, after a fraction

of the time it is most of the way there. So, it is def _possible_ for folks to get a clean/safe burn using wood that has been outside for a good bit less than

a year. To tell folks that it is impossible, or that they shouldn't try stuff and judge for themselves does them a disservice.

Alternatively, the indoor drying process does work (wood in a a dry environment dries, what else would it do?). There have been posters in the past that

have said something akin to 'I bring my just split wood into the house, stack it 5' from the stove, and it is fully seasoned (i.e. it burns great) two days later'.

No one on this thread is suggesting that, in fact it is countering it. In those old threads the methodology was pretty shoddy--folks didn't weigh anything,

own a moisture meter, or have a thermometer on their stove--just said 'yup, goes up really fast after two days in the house, not so much otherwise'.

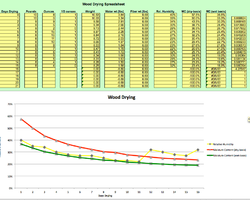

The service BK is providing is to detail his successful, practical alternative to a year of outside drying. Beyond just telling us 'it works', which we should

believe based on his sage advice over the years, he is providing numerical data that supports his claims (a weight curve), and a timescale--a week or two,

not a day or two.

Whether you decide to try something similar is really up to you once you know the timescale involved. Do you have enough heated, ventilated

space in your house to store 2+ weeks of wood, your wood is reasonably free of bugs/mold to the point you wouldn't lose sleep over visions of beetles

crawling everywhere (thanks pen), and you're already paying an energy/$$ cost to humidify your otherwise too dry house? If the answer is yes, then indoor drying

is an option for you.

It really comes down to volume: for a 24/7 burner, the amounts can be so large, we are talking about a large commitment that eats a lot of indoor space.

If you are burning less than a cord of wood a year, then it is probably not that big a deal.

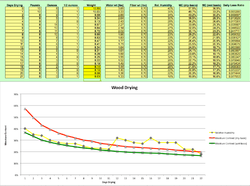

I also think BK is being conservative--I suggested that a split might be dry through and through after several weeks indoors. Clearly, neither he nor I would

claim that w/o data. But if half of the wood volume is at 15% MC and half is at 25%, it will burn just as well as a uniform 20%MC split. This is the nice thing

about the weight method--it tells you about the average MC, which is the most important thing. Having the outside dryer than the inside helps with take-off,

as BK has demonstrated. This is what has fooled less careful burners into thinking their wood was dry--after one day inside it took off fast (and then died

later). BK is getting enough water mass out that over the whole burn cycle, the splits are functionally equivalent to those dried outside after a reasonably short

(but not conveniently short) length of time.

thanks again BK for the experiment!

As a group, we have in the past been unable to agree on an outside seasoning time suggestion, b/c of all the variables of climate, split size etc.

The gen'l guideline 'one year, except dense species which get two' is great (conservative) advice for folks who have the ability to put up a year or two of wood--a

lot of us don't. In reality, with outdoor drying, YMMV. The nature of wood drying has this diminishing returns (decelerating) characteristic, after a fraction

of the time it is most of the way there. So, it is def _possible_ for folks to get a clean/safe burn using wood that has been outside for a good bit less than

a year. To tell folks that it is impossible, or that they shouldn't try stuff and judge for themselves does them a disservice.

Alternatively, the indoor drying process does work (wood in a a dry environment dries, what else would it do?). There have been posters in the past that

have said something akin to 'I bring my just split wood into the house, stack it 5' from the stove, and it is fully seasoned (i.e. it burns great) two days later'.

No one on this thread is suggesting that, in fact it is countering it. In those old threads the methodology was pretty shoddy--folks didn't weigh anything,

own a moisture meter, or have a thermometer on their stove--just said 'yup, goes up really fast after two days in the house, not so much otherwise'.

The service BK is providing is to detail his successful, practical alternative to a year of outside drying. Beyond just telling us 'it works', which we should

believe based on his sage advice over the years, he is providing numerical data that supports his claims (a weight curve), and a timescale--a week or two,

not a day or two.

Whether you decide to try something similar is really up to you once you know the timescale involved. Do you have enough heated, ventilated

space in your house to store 2+ weeks of wood, your wood is reasonably free of bugs/mold to the point you wouldn't lose sleep over visions of beetles

crawling everywhere (thanks pen), and you're already paying an energy/$$ cost to humidify your otherwise too dry house? If the answer is yes, then indoor drying

is an option for you.

It really comes down to volume: for a 24/7 burner, the amounts can be so large, we are talking about a large commitment that eats a lot of indoor space.

If you are burning less than a cord of wood a year, then it is probably not that big a deal.

I also think BK is being conservative--I suggested that a split might be dry through and through after several weeks indoors. Clearly, neither he nor I would

claim that w/o data. But if half of the wood volume is at 15% MC and half is at 25%, it will burn just as well as a uniform 20%MC split. This is the nice thing

about the weight method--it tells you about the average MC, which is the most important thing. Having the outside dryer than the inside helps with take-off,

as BK has demonstrated. This is what has fooled less careful burners into thinking their wood was dry--after one day inside it took off fast (and then died

later). BK is getting enough water mass out that over the whole burn cycle, the splits are functionally equivalent to those dried outside after a reasonably short

(but not conveniently short) length of time.

thanks again BK for the experiment!