Durock strips in hearth

- Thread starter rsiros

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

JimWalshin845

New Member

First time I have seen anyone use Roxul as a floor insulator. I guess they make something now that will take a load. That is fantastic. Roxul is rock wool.... a by product of a mining process and one of the best insulators known to man.

Rsiros, the only concern I would have is the compression factor. Can you tell us what Roxul product you are using?

Thanks,

Jim

Rsiros, the only concern I would have is the compression factor. Can you tell us what Roxul product you are using?

Thanks,

Jim

Which Roxul product will you be using? It looks like 1" Rockboard 35 is R4.1 and would work fine in a Durock sandwich. Though I wouldn't use any Durock strips. Full sheet to sheet contact will spread the compressive load. If concerned about compression they make several higher density Rockboards. But I think from the description that the Rockboard 35 would work fine under a top layer of Durock.

This looks like a nice product for building hearths. How available is it in small quantities of one or 2 sheets? It looks like a 1.5 or 2" sheet would work.

http://www.roxul.com/graphics/RX-NA/Canada/Product Literature/Tech Data/RockBoard35-8-7-07.pdf

This looks like a nice product for building hearths. How available is it in small quantities of one or 2 sheets? It looks like a 1.5 or 2" sheet would work.

http://www.roxul.com/graphics/RX-NA/Canada/Product Literature/Tech Data/RockBoard35-8-7-07.pdf

JimWalshin845

New Member

ansehnlich1 said:I am not a professional, but this setup as I'm reading ain't good. I think your r-value needs to be 6.6 across your entire hearth. Now, how to do that is the question.

Actually this sounds interesting.. and I am not a pro either. But think about the fact that the Roxul is placed directly under the stove and Rsiros uses the Durock sleepers at the legs for support. I don't know if it would pass code but this set up is certainly something that looks good. I looked at some of their products and I think the compression factor was 10% @ 90#/sq/ft. So with a layer or two of durock it would be minimized. The Roxul product sounds like something to be looked into, especially for those that need that 6+R factor.

Are you sure about the asbestos? According to Roxul's website the product is made from basalt rock and slag. They claim that "Roxul materials are free of asbestos".

"GENERAL CHARACTERISTIC OF ROXUL® ROCKWOOL® PRODUCTS: NON-COMBUSTIBLE. WATER REPELLENT. VERMIN & ROT PROOF. ASBESTOS, CFC AND

HCFC FREE PRODUCT & PROCESS. CHEMICALLY INERT. EASY TO HANDLE & CUT. MAINTENANCE FREE."

http://www1.roxul.com/graphics/RX-MY/pdf/MPS_english_Jun07.pdf

Sounds like it would be great for insulating exterior chimney chases before the rock veneer.

"GENERAL CHARACTERISTIC OF ROXUL® ROCKWOOL® PRODUCTS: NON-COMBUSTIBLE. WATER REPELLENT. VERMIN & ROT PROOF. ASBESTOS, CFC AND

HCFC FREE PRODUCT & PROCESS. CHEMICALLY INERT. EASY TO HANDLE & CUT. MAINTENANCE FREE."

http://www1.roxul.com/graphics/RX-MY/pdf/MPS_english_Jun07.pdf

Sounds like it would be great for insulating exterior chimney chases before the rock veneer.

JimWalshin845

New Member

I think perhaps generic rockwool and Roxul products may not be the same thing. If there was asbestos in their product the legal implications, especially given their claims, would be staggering and would shut them down pretty quickly. Perhaps your friend was referring to a different product.

From Roxul:

Roxul Stone Wool products are made of basalt, a volcanic stone.

Roxul Stone Wool products are non-combustible with a melting

point of approximately 1000°C. Roxul Stone Wool products are

particularly suitable for thermal insulation, fire protection and sound

reduction/absorption.

From Roxul:

Roxul Stone Wool products are made of basalt, a volcanic stone.

Roxul Stone Wool products are non-combustible with a melting

point of approximately 1000°C. Roxul Stone Wool products are

particularly suitable for thermal insulation, fire protection and sound

reduction/absorption.

This came from a google search:

Many people compare asbestos to Rockwool® because they are both mineral fiber, but Rockwool® is not asbestos. Asbestos, when friable, floats in the air for a very long time; Rockwool® does not. Asbestos has points and barbs that stick in your lungs; Rockwool® does not. Asbestos can never be broken down by your body's immune system, once it's in your lungs, it's there forever. Rockwool® can be broken down and absorbed.

http://www.everything2.com/index.pl?node=Rockwool

and:

http://www.rockwool.co.uk/sw66371.asp

Many people compare asbestos to Rockwool® because they are both mineral fiber, but Rockwool® is not asbestos. Asbestos, when friable, floats in the air for a very long time; Rockwool® does not. Asbestos has points and barbs that stick in your lungs; Rockwool® does not. Asbestos can never be broken down by your body's immune system, once it's in your lungs, it's there forever. Rockwool® can be broken down and absorbed.

http://www.everything2.com/index.pl?node=Rockwool

and:

http://www.rockwool.co.uk/sw66371.asp

JimWalshin845

New Member

BeGreen...

A by product does not have to contain the original ingredient. I am sure that Roxul has no asbestos in it.

Addit... Asbestos in a capsulated form is not harmful, if it is broken down so it can be air-born and you are exposed to it for a period... well... you may have serious health problems.

When I was a kid I worked for a garage and did brake jobs.... guess what the major component was for break shoes?

Second Addit... I grew up in a Sears Kit House... the ceiling insulation was rock wool.

A by product does not have to contain the original ingredient. I am sure that Roxul has no asbestos in it.

Addit... Asbestos in a capsulated form is not harmful, if it is broken down so it can be air-born and you are exposed to it for a period... well... you may have serious health problems.

When I was a kid I worked for a garage and did brake jobs.... guess what the major component was for break shoes?

Second Addit... I grew up in a Sears Kit House... the ceiling insulation was rock wool.

key word - imagine. where is the data?

I guess I'm not getting the picture here. Asbestos is under intense scrutiny by OSHA and the courts.

"The fiber glass (FG) and rock/slag wool (RSW) manufacturers have developed a Health and Safety Partnership Program (HSPP) with the participation and oversight of the Occupational Safety and Health Administration (OSHA). Among its many provisions the HSPP includes the continuing study of FG and RSW workplace concentrations in manufacturing facilities operated by FG/RSW producers and among their customers and end users. This analysis estimates the probable cumulative lifetime exposure (fiber-months/cubic centimeter [f-months/cc]) to those who install FG and RSW insulation in residential, commercial, and industrial buildings in Canada and the United States. Both professional and do-it-yourself (DIY) cohorts are studied and the estimated working lifetime exposures are compared with benchmark values derived from an analysis of the epidemiological studies of FG and RSW manufacturing cohorts. The key finding of this analysis is that both of these end-user cohorts are likely to have substantially lower cumulative lifetime exposures than the manufacturing cohorts. As the most recent updates of the epidemiological studies concluded that there was no significant increase in respiratory system cancer among the manufacturing cohorts, there is likely to be even less risk for the installer cohorts. This analysis also underscores the wisdom of stewardship activities in the HSPP, particularly those directed at measuring and controlling exposure. "

http://tinyurl.com/374oat

edit: brake shoes are one of the few exceptions that are allowed to contain asbestos. But bringing up a strawman doesn't make Rockwool or Rockboard contain asbestos. Did you know there is chlorine - a deadly poison in common salt aka sodium chloride? :bug:

I guess I'm not getting the picture here. Asbestos is under intense scrutiny by OSHA and the courts.

"The fiber glass (FG) and rock/slag wool (RSW) manufacturers have developed a Health and Safety Partnership Program (HSPP) with the participation and oversight of the Occupational Safety and Health Administration (OSHA). Among its many provisions the HSPP includes the continuing study of FG and RSW workplace concentrations in manufacturing facilities operated by FG/RSW producers and among their customers and end users. This analysis estimates the probable cumulative lifetime exposure (fiber-months/cubic centimeter [f-months/cc]) to those who install FG and RSW insulation in residential, commercial, and industrial buildings in Canada and the United States. Both professional and do-it-yourself (DIY) cohorts are studied and the estimated working lifetime exposures are compared with benchmark values derived from an analysis of the epidemiological studies of FG and RSW manufacturing cohorts. The key finding of this analysis is that both of these end-user cohorts are likely to have substantially lower cumulative lifetime exposures than the manufacturing cohorts. As the most recent updates of the epidemiological studies concluded that there was no significant increase in respiratory system cancer among the manufacturing cohorts, there is likely to be even less risk for the installer cohorts. This analysis also underscores the wisdom of stewardship activities in the HSPP, particularly those directed at measuring and controlling exposure. "

http://tinyurl.com/374oat

edit: brake shoes are one of the few exceptions that are allowed to contain asbestos. But bringing up a strawman doesn't make Rockwool or Rockboard contain asbestos. Did you know there is chlorine - a deadly poison in common salt aka sodium chloride? :bug:

ansehnlich1

Retired Hearth.com Member

Jim Walsh said:ansehnlich1 said:I am not a professional, but this setup as I'm reading ain't good. I think your r-value needs to be 6.6 across your entire hearth. Now, how to do that is the question.

Actually this sounds interesting.. and I am not a pro either. But think about the fact that the Roxul is placed directly under the stove and Rsiros uses the Durock sleepers at the legs for support. I don't know if it would pass code but this set up is certainly something that looks good. I looked at some of their products and I think the compression factor was 10% @ 90#/sq/ft. So with a layer or two of durock it would be minimized. The Roxul product sounds like something to be looked into, especially for those that need that 6+R factor.

Am I wrong in assuming a 5 x 5 foot hearth with 2 inch strips of durock for support, say every foot, would equal about 5 sq ft. of durock total? And assuming that durock is not r-6.6, which it would not be unless it was 13 inches thick, would mean that 5 sq. feet of that hearth would not be up to mfr. spec. on this stove? And if it's onlyy 3, or 4 sq. feet total, should I be comfortable that amount is not r-6.6?

I'm not debating the Roxul is a fine product to use, the question I have is heat transfer through those strips of durock? ....., or steel for that matter? This stove obviously gets pipin' hot underneath to require a 6.6 r hearth setup no?

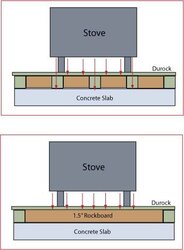

The Roxul product that I bought is the rht60. This stuff is widely used in Europe and Canada. It is comparable in price to fiberglass, but seemingly superior in quality. I'm not sure why it's not widely avaiable here- probably some red tape or monopoly thing. I wanted the "board" product, but it was not available. When I tore up my hearth, I found that the slate was on a nice concrete pad (probably about 3"). My stove will be mounted on the pad and a small portion will extend back into the fireplace (heart mount stove). So I have the concrete slab, Durock strips, Roxul to fill between strips, Durock over that, and tile over that. My concern is what ansehnlich wrote... about the r-value extending all the way through the hearth, but I'm sure that the floor joists will be well protected.

mikeathens

Minister of Fire

I'd say definitely do some more research on this. I just don't want you to end up with an R value that's a bit shy of the requirment - and figure it out AFTER you build it (that's what I did). And I wouldn't necessarily rely on the "professionals" (i.e. local stove shop) for advice. I have found that the knowledege floating around this web page and through memebers is WAY more reliable - at least compared to the loacl VC/Morso delaer.

I've researched this to death, and quickly learned that the local shops are pretty much clueless about my stove and many products. This forum has been guiding me every step of the way. I found that most of the advice that you get here leans toward extreme caution... which is a good thing. As a home owner, one needs to take all facts and opinions gained into consideration, and make an informed decision about which way to go. Any word on using the Durock strips? I think any extreme heat that permeates into my hearth will probably not do so in "hot spots", but more as an even, radiating heat which would be absorbed in the Roxul. One never knows... but even if there are hot spots, there is 3" of concrete below the insulation. I'll also have some sheet metal under the Roxul, and I also have a home-made heat shield to lay under the stove.

One other thing... local building inspector is a friend. He'll check my manual and ask if I have my r-6.6 and go about his day. I tend to think that the scrutiny that you get here for your project is greater and more fact-based than anything that one man/woman (anyone know of a female building inspector?) can offer.

I think the point is that by using thick strips of durock with insulation in between the thermal barrier created by the insulation, there is a conductive path for heat that has lower resistance than the insulation. With a continuous insulation barrier this is not an issue. But given there is a concrete slab underneath that, you are likely well covered. If there was wood underneath I would not use the durock strips or loose insulation.

It looks like Rockboard RHT60 has good compressive strength, the stove weight would be spread over a large area. This could be enhanced by a layer of sheetmetal under the durock. Thus I would probably minimize the support struts. If the stove weighs 500# and is sitting on 2x2" feet (4 sq in.) or about 31# / sq in., the top load should be well within the compression rating for the durock/metal/rockboard sandwich. In this case, many supporting strips are overkill. But at least consider putting a top layer of sheet metal over the insulation as a radiant barrier.

FWIW, I'm surprised that Hearthstone doesn't make bottom heat shields. That would make this a moot point.

It looks like Rockboard RHT60 has good compressive strength, the stove weight would be spread over a large area. This could be enhanced by a layer of sheetmetal under the durock. Thus I would probably minimize the support struts. If the stove weighs 500# and is sitting on 2x2" feet (4 sq in.) or about 31# / sq in., the top load should be well within the compression rating for the durock/metal/rockboard sandwich. In this case, many supporting strips are overkill. But at least consider putting a top layer of sheet metal over the insulation as a radiant barrier.

FWIW, I'm surprised that Hearthstone doesn't make bottom heat shields. That would make this a moot point.

Attachments

JimWalshin845

New Member

This all sounds wonderful but I am now very circumspect about the usage here on the floor. All the diagrams I perused on the Roxul site were for wall and ceiling applications.

From what I understand you are going to finish the hearth in porcelain tile, I think over time the floor will compress around the stove and your tiles will crack and grout joints disintegrate.

Rsiros, did you contact Roxul and ask them is this OK on floor applications?

From what I understand you are going to finish the hearth in porcelain tile, I think over time the floor will compress around the stove and your tiles will crack and grout joints disintegrate.

Rsiros, did you contact Roxul and ask them is this OK on floor applications?

Hey thanks web! The Roxul compressive ratings for RHT60 are: ASTM C 165 at 10% 104 psf

at 25% 230 psf

I'm not sure what these #s mean...when compressed 10%, it can carry a 104 psf load? I don't have the rockboard product;mine is semi-rigid. But with some sheet metal on top of it, I'll be able to reduce the amount of spacing between the strips. What do you guys think the best spacing technique would be when taking the feet into consideration?

at 25% 230 psf

I'm not sure what these #s mean...when compressed 10%, it can carry a 104 psf load? I don't have the rockboard product;mine is semi-rigid. But with some sheet metal on top of it, I'll be able to reduce the amount of spacing between the strips. What do you guys think the best spacing technique would be when taking the feet into consideration?

Jim, I talked to the guy that sold me the Roxul and he said floor use is ok, but sandwiching is not recommended. I agree with your thoughts of the material not being rigid enough to sandwich, with compression and movement being likely. I want to keep the supports as slim as possible though.

I think this is a non-issue, especially with a sheet of metal below the durock. But using metal studs will give you peace of mind.

mikeathens

Minister of Fire

Yup...go with metal studs. I assume you only want to do this once? I would. This isn't necessarily fun work, and I'm sure you have better things to do with your time than build a hearth and tear it out again two weeks later. Spend the extra cash. It couldn't possibly be that much more, and it will probably be cheaper in the long run.

mikeathens

Minister of Fire

You be adding better support, taking out a layer of (possibly questionable) R value material, and probably won't have to watch your tile crack and mortar crumple.

Metal studs are thinner, allowing more room for insulation. And you can pop rivet the top sheetmetal skin right to them. That makes the durock base act as one unit for extra rigidity. For even more peace of mind double up the top layer of durock.

ansehnlich1

Retired Hearth.com Member

This site shows concrete to be .08 r per inch....that ain't much. http://www.sizes.com/units/rvalue.htm

And I know steel conducts heat. That's all I'm going to say on this matter.

I would call the factory, get a knowledgeable rep on the phone, and ask him/her what to use for a hearth/hearthpad that meets the requirement of r = 6.6 AND I would come back here and post his/her response...... I'm dying to know.

I designed the hearth for my Jotul Oslo and I know its 4 layers solid durock (2 inches) layed in, then half inch of mortar on top that, then brick..... r = 1.54

I would not consider burning a stove in my home if I was not absolutely certain the hearth was built to spec.

And I know steel conducts heat. That's all I'm going to say on this matter.

I would call the factory, get a knowledgeable rep on the phone, and ask him/her what to use for a hearth/hearthpad that meets the requirement of r = 6.6 AND I would come back here and post his/her response...... I'm dying to know.

I designed the hearth for my Jotul Oslo and I know its 4 layers solid durock (2 inches) layed in, then half inch of mortar on top that, then brick..... r = 1.54

I would not consider burning a stove in my home if I was not absolutely certain the hearth was built to spec.

- Status

- Not open for further replies.

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 13

- Views

- 733

- Replies

- 23

- Views

- 935

- Replies

- 1

- Views

- 971