I'm often thinking of replacing my 45 year old HS Tarm wood boiler with a more efficient boiler. Does anyone have an idea of the price of a E100 boiler from Alternative Heating Systems? I hate to take up their time if I'm not ready to buy. Also, does it qualify for rebates? Thanks.

E100 wood boiler

- Thread starter Tightwad

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have an stainless steel E100 for sale - used it for about 7 years. In excellent condition. Comes with factory vent hood, premium stainless insulated pipe to connect to chimney, a huge roll of premium square 2100*F door gasket AND custom professional moulds to make all your own refractory & replacement bricks (I used to do this for a living). Has a DHW built-in coil which I never used.

This is the most fantastic wood burner I have ever seen. I am heating a 2600 s/f house & 800 s/f separate garage through an underground line and also domestic hot water. Using pex in concrete, fan coil, and baseboards. When the temps are down to -10*C I use 4 - 5 split pieces per day, colder than that maybe up to 7 pieces maximum. We keep the house between 22*C - 24*C. It is installed in my basement, using outside air for burning. I am including a fire damper which I added to the air intake (visible in photo of back of e100). I could go on and on about this thing, but I'll stop here.

Health issues have caught up with us - we always cut and split & handled all our wood by hand from standing trees - just can't do it any more. The unit is currently still installed. I will sell reasonable - the only catch - I am in southern Ontario - near Oshawa.

Let me know if you might be interested.

This is the most fantastic wood burner I have ever seen. I am heating a 2600 s/f house & 800 s/f separate garage through an underground line and also domestic hot water. Using pex in concrete, fan coil, and baseboards. When the temps are down to -10*C I use 4 - 5 split pieces per day, colder than that maybe up to 7 pieces maximum. We keep the house between 22*C - 24*C. It is installed in my basement, using outside air for burning. I am including a fire damper which I added to the air intake (visible in photo of back of e100). I could go on and on about this thing, but I'll stop here.

Health issues have caught up with us - we always cut and split & handled all our wood by hand from standing trees - just can't do it any more. The unit is currently still installed. I will sell reasonable - the only catch - I am in southern Ontario - near Oshawa.

Let me know if you might be interested.

pblormis

Member

Would love info on the molds for refractories. 13 years of use and need to be replaced.I have an stainless steel E100 for sale - used it for about 7 years. In excellent condition. Comes with factory vent hood, premium stainless insulated pipe to connect to chimney, a huge roll of premium square 2100*F door gasket AND custom professional moulds to make all your own refractory & replacement bricks (I used to do this for a living). Has a DHW built-in coil which I never used.

This is the most fantastic wood burner I have ever seen. I am heating a 2600 s/f house & 800 s/f separate garage through an underground line and also domestic hot water. Using pex in concrete, fan coil, and baseboards. When the temps are down to -10*C I use 4 - 5 split pieces per day, colder than that maybe up to 7 pieces maximum. We keep the house between 22*C - 24*C. It is installed in my basement, using outside air for burning. I am including a fire damper which I added to the air intake (visible in photo of back of e100). I could go on and on about this thing, but I'll stop here.

Health issues have caught up with us - we always cut and split & handled all our wood by hand from standing trees - just can't do it any more. The unit is currently still installed. I will sell reasonable - the only catch - I am in southern Ontario - near Oshawa.

Let me know if you might be interested.

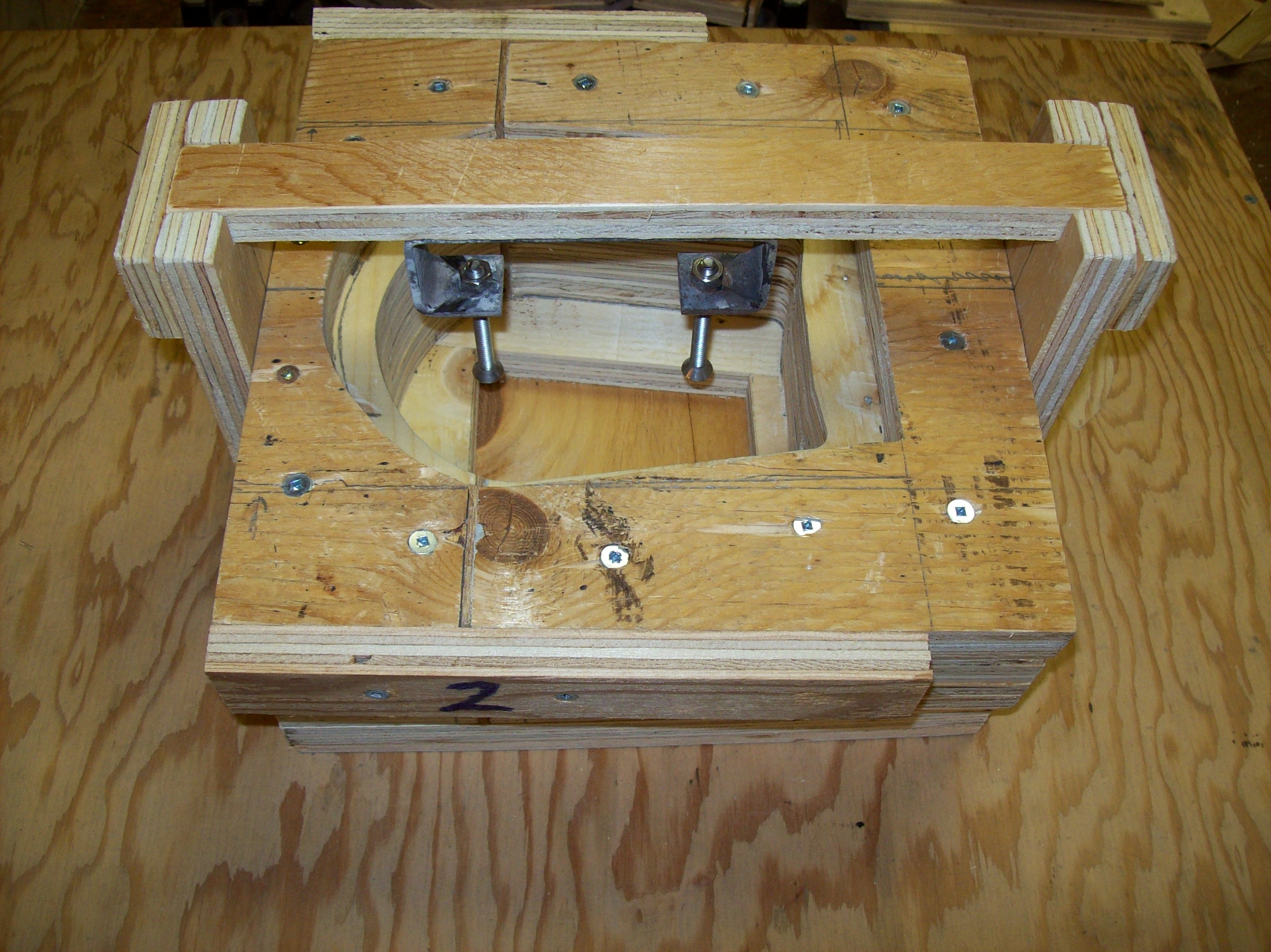

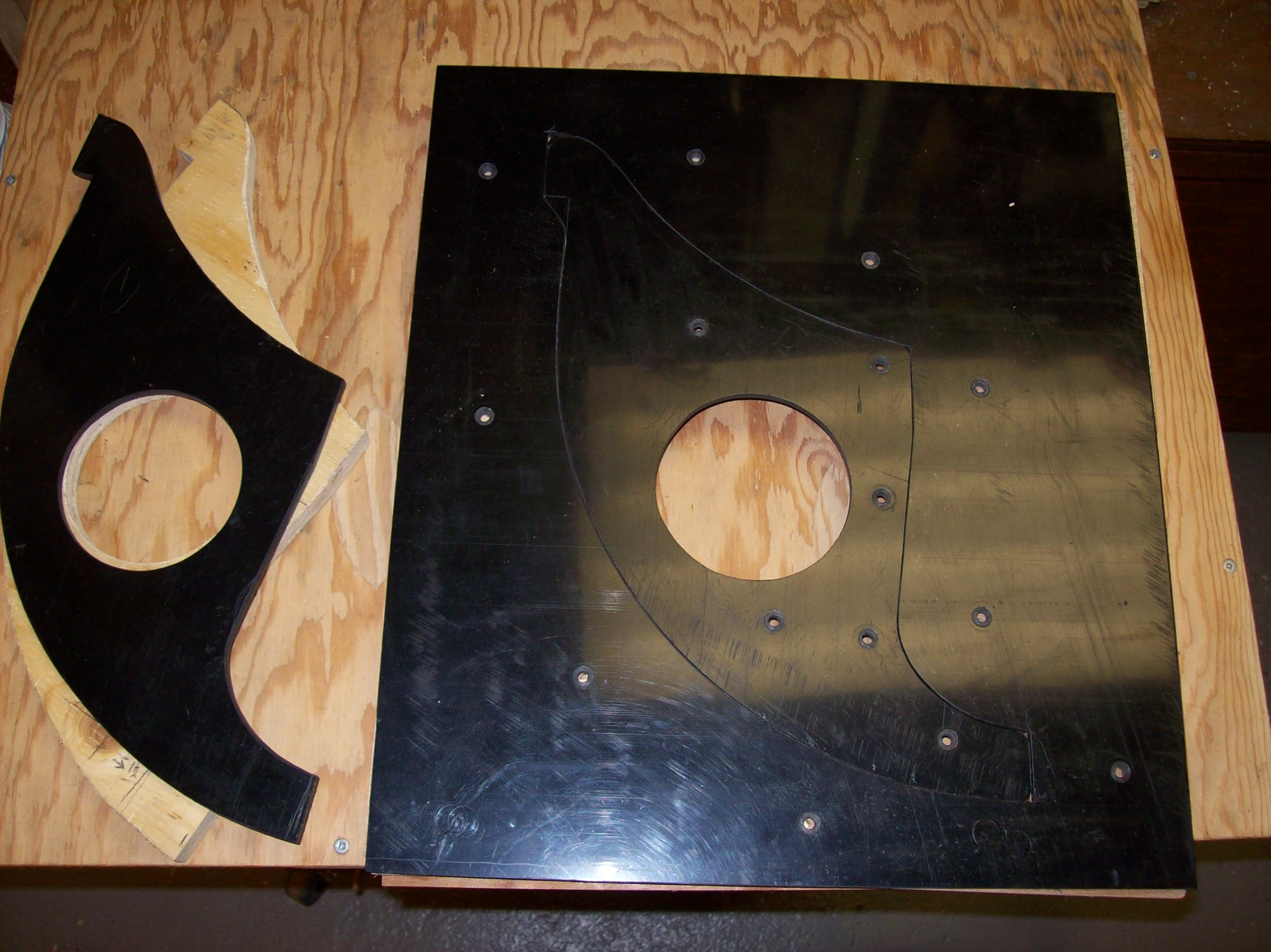

View attachment 320135 View attachment 320136

Old_Seton_Guy

New Member

Hi Scott. Did you ever sell the E100? Thanks, DougI have an stainless steel E100 for sale - used it for about 7 years. In excellent condition. Comes with factory vent hood, premium stainless insulated pipe to connect to chimney, a huge roll of premium square 2100*F door gasket AND custom professional moulds to make all your own refractory & replacement bricks (I used to do this for a living). Has a DHW built-in coil which I never used.

This is the most fantastic wood burner I have ever seen. I am heating a 2600 s/f house & 800 s/f separate garage through an underground line and also domestic hot water. Using pex in concrete, fan coil, and baseboards. When the temps are down to -10*C I use 4 - 5 split pieces per day, colder than that maybe up to 7 pieces maximum. We keep the house between 22*C - 24*C. It is installed in my basement, using outside air for burning. I am including a fire damper which I added to the air intake (visible in photo of back of e100). I could go on and on about this thing, but I'll stop here.

Health issues have caught up with us - we always cut and split & handled all our wood by hand from standing trees - just can't do it any more. The unit is currently still installed. I will sell reasonable - the only catch - I am in southern Ontario - near Oshawa.

Let me know if you might be interested.

View attachment 320135 View attachment 320136

same here. resco cement is what i use kricon 32-70 better than than what they use.i can do the center bricks.do hot have a pattern for the big ones.thanks.Would love info on the molds for refractories. 13 years of use and need to be replaced.

muncybob

Minister of Fire

I would be interested in seeing the original and the copy. Better yet would love to see this project on You Tube

Hi Doug,Hi Scott. Did you ever sell the E100? Thanks, Doug

The E100 is still for sale. I really have not actively done anything to sell it. It is still part of my system which I and using but not firing the boiler. So YES my E100 stainless is for sale along with a everything needed to hook it up and the forms to make all the refractory. Scott

It is a fair bit of work to make the molds as they need to be fairly precise and you need to be able to take them apart to get the finished pieces out, then put them together again precisely. I bought my refractory from an industrial boiler refractory company. Far better than the refractory that came with my boiler.Would love info on the molds for refractories. 13 years of use and need to be replaced.

I changed the refractory design a bit so that the parts that wear could be replaced instead of replacing the entire refractory. Also I made the plug with a double seal instead of the factory single seal. My original factory refractory was junk after 3 years ?????? This was at the time Jeff was not owner any more. Wood Gun would not do anything for me so I made my own. I used the new refractory for 3 years - the heating performance of the boiler was no different than with the factory refractory.

With these molds you can make a batch of parts in about an hour.

Hi Bob,I would be interested in seeing the original and the copy. Better yet would love to see this project on You Tube

I'm not a youtuber - all I have is photos but there are before and after. The pieces of old refractory in the photo was all that survived after 3 years of burning - the rest crumbled. I was going through wood gun factory center bricks every couple weeks. Initially I started making replacements by cutting and slotting wood stove fire bricks. Those were lasting a couple months. Before my refractory started getting too bad I started experimenting with lining the inside of the original wood gun center tube by shaping wood stove fire bricks.

That worked fairly well but the original refractory was still deteriorating where the center brick rests on the ledge. So the next logical step was to make my of molds. This is the result.

I have attached some photos of the molds. Also I have the patterns I made to make the molds. The refractory fits pretty much perfect - the tubes line up perfect, no shimming. Changing out any worn part is very easy as I made everything so it would come apart without using a hammer.

Just a thought................ If you are making center bricks, using a copy is fine. If you are considering making the main refractory, you would probably be better off tracing the shape of your boiler (with the refractory removed). That way you can make a pattern of the entire seat (where the refractory sits) cut it vertically and compare to make sure both sides are exactly the same. Just my 5 cents (but speaking from experience - I have done this). Scott.

Hi Krinkov,for the molds i think i will buy 1 and copy it.the shipping is the killer.

Just a thought................ If you are making center bricks, using a copy is fine. If you are considering making the main refractory, you would probably be better off tracing the shape of your boiler (with the refractory removed). That way you can make a pattern of the entire seat (where the refractory sits) cut it vertically and compare to make sure both sides are exactly the same. Just my 5 cents (but speaking from experience - I have done this). Scott.

sloeffle

Minister of Fire

Thank you Sloeffle . Don't own a cnc - all done old school - by hand.@Scott7 those molds and refractory are impressive. Did you make the molds with a CNC machine ?

That is a great idea - thank you for that. When I made my parts I was coating the moulds with a thin layer of lard - this is how they did it at the place I bought the refractory cement. Your method sounds like it would be better as you would only need to do it once.thank for the info.i clear coated my forms with automotive clear.releases the brick better.i use kricon 32-70 by resco products.

brenndatomu

Minister of Fire

X2!@Scott7 those molds and refractory are impressive.

muncybob

Minister of Fire

WOW! I am impressed, wish I had the talent you have.

How on earth were you going through center bricks like that!? I'm on season 3 with mine and that's with burning a lot of oak. I dread removing them this summer as I think the lips they rest on may be about worn out.

Thank you for the compliments, you are very kind.

I don't know any more about refractory than the next guy, but I suspect there was a flaw in the refractory that was being produced at the factory at the time I bought (when Jeff had sold and was no longer running the business). I have always burned Hickory which is a much denser wood than maple/oak so it does burn hotter and longer - maybe that was the problem???? The refractory bricks I made are lasting for many seasons. You can see my original main refractory block - it is also disintegrating - I only got 2 seasons from that. I cannot explain it, but in order to use the boiler I had to do something about it. I am in Canada so shipping (of the entire new refractory) would have been very costly with no guarantee it would be any better. At the time health issues were not an issue, so I set about making these moulds thinking it was a good investment. These moulds are made to last. I am hoping I will find someone who will be able to get good use from them.

I don't know any more about refractory than the next guy, but I suspect there was a flaw in the refractory that was being produced at the factory at the time I bought (when Jeff had sold and was no longer running the business). I have always burned Hickory which is a much denser wood than maple/oak so it does burn hotter and longer - maybe that was the problem???? The refractory bricks I made are lasting for many seasons. You can see my original main refractory block - it is also disintegrating - I only got 2 seasons from that. I cannot explain it, but in order to use the boiler I had to do something about it. I am in Canada so shipping (of the entire new refractory) would have been very costly with no guarantee it would be any better. At the time health issues were not an issue, so I set about making these moulds thinking it was a good investment. These moulds are made to last. I am hoping I will find someone who will be able to get good use from them.

Hello Krinkov - So far, the only place I have offered my boiler and moulds for sale is here on the Hearth forum. I am hoping that someone will see the value of purchasing the boiler and moulds together. I am casually looking around to find a heating contractor who might be willing to trade a heat pump and/or natural gas boiler for my boiler. So, for the moment, my thinking is to keep the boiler, the moulds, and all the accessory boiler stuff together as one package.how much for the brick molds if you could make a set?

As far as making and selling bricks, my moulds are for the design I created. My center bricks are much thicker than the ones you would buy from the factory. No offense to you, but I would rather not get into making/shipping bricks.

If you want to save some money on center bricks - it is not very difficult to make them from wood stove fire bricks. Last time I bought them they were less than $5 each. You can cut them to width/length with a $5 diamond blade using any angle grinder. You can use a Dremel (or any rotary tool) with a diamond cutter (you can buy sets of these on Amazon for $10 - $15) to cut the slots. I was doing it before I made my moulds - you can see one I made in my photos above - the one with the old refractory. If you have an angle grinder and rotary tool, the diamond blades/bits don't cost much and you can make many sets of center bricks. The wood stove fire bricks are about the same thickness as the factory center bricks and are pretty durable. If you are patient and a little handy, they really are not difficult to make.

Similar threads

- Replies

- 0

- Views

- 224

- Replies

- 0

- Views

- 301

- Replies

- 6

- Views

- 1K

- Replies

- 19

- Views

- 799