I don't have a problem with design changes, that is normal. But, do not sell parts that are known have changed without stating so. New Horizon parts page simply states Eko Model 25. It gives no hint that it may not fit or that the design has changed. The alteration required was difficult and time consuming. If you buy an oil filter for your car, you expect it to fit. You should not have to spend time and effort modifying it to make it work.Could we be giving the manufacturer too much credit? Would anyone be disappointed to find that the shape was designed to facilitate removal from the mold?

Eko Orlan Model 25 Nozzle

- Thread starter JTWALL

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Fred61

Minister of Fire

I agree on that. I was referring to the taper on the inside.I don't have a problem with design changes, that is normal. But, do not sell parts that are known have changed without stating so. New Horizon parts page simply states Eko Model 25. It gives no hint that it may not fit or that the design has changed. The alteration required was difficult and time consuming. If you buy an oil filter for your car, you expect it to fit. You should not have to spend time and effort modifying it to make it work.

avc8130

Minister of Fire

Could we be giving the manufacturer too much credit? Would anyone be disappointed to find that the shape was designed to facilitate removal from the mold?

Yup. Clearly a draft angle for mold release. Common in just about any cast design regardless of material or application.

ac

mr.fixit

Feeling the Heat

Maybe we should modify that nozzle design by angling it in one direction to get a swirling-vortex flame going

Nofossil

Moderator Emeritus

I'm pretty sure that this is a glimpse into the super-secret world of gasifier design. This is not information granted to ordinary mortals. It couldn't possibly be something so prosaic as mold release - it has to be something to do with adiabatic flame propagation, the secret fourth law of thermodynamics, and quantum mechanics.

Fred61

Minister of Fire

Wow! It could be that or it could be that Zennon has his wife making them at her Wednesday night ceramics class and they look nothing like the originals.I'm pretty sure that this is a glimpse into the super-secret world of gasifier design. This is not information granted to ordinary mortals. It couldn't possibly be something so prosaic as mold release - it has to be something to do with adiabatic flame propagation, the secret fourth law of thermodynamics, and quantum mechanics.

barnartist

Minister of Fire

I must say, after absorbing as much of JTWALL's posts regarding the new nozzle and its poor fit, I can't convince myself that the tapered design means anything. I hope I am wrong and it is some big improvement. Having said that I would buy a new one if I knew it would fit out of the box.

Nofossil, I like your idea of patching up the nozzle. How is it working out for you? Do you use a layer of firebricks like some people are using?

Lastly, I desperately need to replace my original lower chamber blocks. I see the new ones are a complete different design. I would LOVE to hear any comments about how these are working.

Nofossil, I like your idea of patching up the nozzle. How is it working out for you? Do you use a layer of firebricks like some people are using?

Lastly, I desperately need to replace my original lower chamber blocks. I see the new ones are a complete different design. I would LOVE to hear any comments about how these are working.

I understand they work well, but you might want to verify the new design will fit your boiler. I have read where the new design is too high in some instances.I must say, after absorbing as much of JTWALL's posts regarding the new nozzle and its poor fit, I can't convince myself that the tapered design means anything. I hope I am wrong and it is some big improvement. Having said that I would buy a new one if I knew it would fit out of the box.

Nofossil, I like your idea of patching up the nozzle. How is it working out for you? Do you use a layer of firebricks like some people are using?

Lastly, I desperately need to replace my original lower chamber blocks. I see the new ones are a complete different design. I would LOVE to hear any comments about how these are working.

mr.fixit

Feeling the Heat

I have the new style lower blocks going on 2 seasons,and one just broke apart this week.When they all fail I am just going to use regular firebrick.You can buy alot of regular firebrick at menards for what they want for those precast ones.I must say, after absorbing as much of JTWALL's posts regarding the new nozzle and its poor fit, I can't convince myself that the tapered design means anything. I hope I am wrong and it is some big improvement. Having said that I would buy a new one if I knew it would fit out of the box.

Nofossil, I like your idea of patching up the nozzle. How is it working out for you? Do you use a layer of firebricks like some people are using?

Lastly, I desperately need to replace my original lower chamber blocks. I see the new ones are a complete different design. I would LOVE to hear any comments about how these are working.

One thing that makes a difference on life of these and the nozzle is the amount of wood that is consumed by the boiler.I go thru 10-11 full cord a season,maybe twice as much as some others with less heat load.

Although the overlay works good for me,if your nozzle is worn down to the air passages,you may have to build that up first and then put the overlay in.

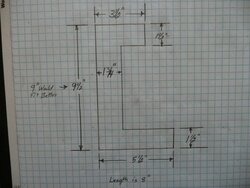

Could you upload a photo of the new style lower blocks and include some dimensions? Thanks!I have the new style lower blocks going on 2 seasons,and one just broke apart this week.When they all fail I am just going to use regular firebrick.You can buy alot of regular firebrick at menards for what they want for those precast ones.

One thing that makes a difference on life of these and the nozzle is the amount of wood that is consumed by the boiler.I go thru 10-11 full cord a season,maybe twice as much as some others with less heat load.

Although the overlay works good for me,if your nozzle is worn down to the air passages,you may have to build that up first and then put the overlay in.

barnartist

Minister of Fire

You can see what they look like on the New Horizon site, but your right JT there are no measurements on anything there. I like that shape but I can see those things cracking about halfway down the curve and then thats a real failure.

Thanks. I looked at them on the New Horizon site awhile ago. I was hoping for a front view without any obstructions (standard firebrick removed). Most likely' I would try to fabricate my own.You can see what they look like on the New Horizon site, but your right JT there are no measurements on anything there. I like that shape but I can see those things cracking about halfway down the curve and then thats a real failure.

mr.fixit

Feeling the Heat

barnartist

Minister of Fire

Thanks Fixit. The old ones you pictured, were they the DIY variety? Thats how I pictured they would break. I wonder about beefing up that side if it would help much, or can some steel be added to the mix for strength like when pouring concrete?

Fred61

Minister of Fire

Thinking about what the blocks accomplish. They limit the amount of flow that would go directly up the more central fire tubes and cause the hot gasses to swirl around and more evenly distribute the flow up the tubes so I would say that any design that accomplishes that would work. One important feature would be to design them for easy ash removal.

barnartist

Minister of Fire

You got me thinking Fred... "to evenly distribute the flow up the tubes" My setup has always included the big arched firebrick in the rear of the chamber (behind the catch blocks). Maybe I should not even have that piece in there? Ive had my eko since '05 and have always had the same lower chamber blocks. I remember in the past this lower chamber directing of gasses being called a labrinth or something I think. was the idea to catch the gasses, direct them forward toward the doors, then back around the sides to the rear. Is that still the goal most people are after?

mr.fixit

Feeling the Heat

Th

If you cast your own get some small stainless steel finishing nails and add to the mix.

They were from the importer and had stainless steel needles cast in them.Thanks Fixit. The old ones you pictured, were they the DIY variety? Thats how I pictured they would break. I wonder about beefing up that side if it would help much, or can some steel be added to the mix for strength like when pouring concrete?

If you cast your own get some small stainless steel finishing nails and add to the mix.

So, the old one failed on the side?Thanks. I looked at them on the New Horizon site awhile ago. I was hoping for a front view without any obstructions (standard firebrick removed). Most likely' I would try to fabricate my own.

Fred61

Minister of Fire

My U-blocks slide up to the case that contains the fire tubes and if I remember correctly, if I squint down through the center of the U-blocks there is a small gap that allows some gasses up the center tubes directly from the center of the blocks. The remaining gasses spill over the top and move forward exiting the front of the blocks and around both sides toward the fire tubes.You got me thinking Fred... "to evenly distribute the flow up the tubes" My setup has always included the big arched firebrick in the rear of the chamber (behind the catch blocks). Maybe I should not even have that piece in there? Ive had my eko since '05 and have always had the same lower chamber blocks. I remember in the past this lower chamber directing of gasses being called a labrinth or something I think. was the idea to catch the gasses, direct them forward toward the doors, then back around the sides to the rear. Is that still the goal most people are after?

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 962

- Replies

- 0

- Views

- 941

- Replies

- 18

- Views

- 3K

- Replies

- 10

- Views

- 661