Guys,

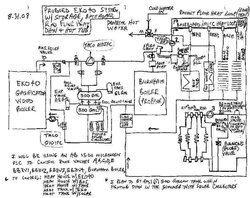

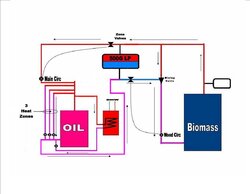

Attached is my proposed system layout for my new EKO40 I am picking up in a few weeks. Please take a look at the detailed layout and let me know what changes should be made (and why).

I have had the Burnham boiler, (2) zones of radiant floor heat (using the Heat Link brand Stat Link controller and zone valves) and (1) zone of baseboard heat in operation for approx. 6 years and it works great !

!

I plan to control the entire system with an AB (Allen Bradley) Micrologix 1500 PLC which has (4) analog inputs and (2) analog outputs (both are 0-20 mA) along with many digital I/O.

However, I am not quite sure of the best location/what type/brand to use for my 4-20mA temp sensors. Does anyone have experience with a specific brand of temp sensor that are reasonable priced and of good quality. Also, where would be the best location to put these and exactly how many would be required to best/most efficiently control the entire system (I can add additional sensors/analog cards if needed).

I look forward to getting your feedback and will share my results of the system (once it's up and running) with anyone who is interested.

Thanks,

BC

Attached is my proposed system layout for my new EKO40 I am picking up in a few weeks. Please take a look at the detailed layout and let me know what changes should be made (and why).

I have had the Burnham boiler, (2) zones of radiant floor heat (using the Heat Link brand Stat Link controller and zone valves) and (1) zone of baseboard heat in operation for approx. 6 years and it works great

!

!I plan to control the entire system with an AB (Allen Bradley) Micrologix 1500 PLC which has (4) analog inputs and (2) analog outputs (both are 0-20 mA) along with many digital I/O.

However, I am not quite sure of the best location/what type/brand to use for my 4-20mA temp sensors. Does anyone have experience with a specific brand of temp sensor that are reasonable priced and of good quality. Also, where would be the best location to put these and exactly how many would be required to best/most efficiently control the entire system (I can add additional sensors/analog cards if needed).

I look forward to getting your feedback and will share my results of the system (once it's up and running) with anyone who is interested.

Thanks,

BC