[Edit:

First consider the 'Garth B' solution. Wiring 120VAC over to a hot flue and back might be a little dodgey but it's nice and simple.

https://www.hearth.com/econtent/index.php/forums/viewthread/80894/P15/#973718

[quote author="Garth B" date="1319066537"]I installed an adjustable snapdisc (18$) on the flue and wired it in paralel with a timer which are both in series with a lightswitch and the fan on my econoburn. Have been set up like this for 2 years and has been working great. I start a fire, turn the timer to 15-20min which gives the flue gas time to heat up and close the snapdisc, then when the flue gas drops below 150 it shuts the fan down. The lightswitch shuts the fan down while I load wood so I dont have to shut the boiler and circ pump off with the main switch. I will be posting pics soon[/quote]

]

The topic comes up from time to time and is currently being discussed elsewhere.

My boiler control includes end of burn draft fan shutdown, but my control also has to control everything else as well since my RK2001U went tango uniform. This is confusing, and so it's not the best example if all a guy wants is just the draft fan shutdown feature.

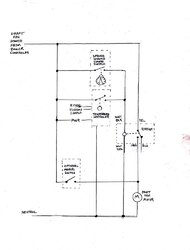

What you do is take the hot wire that goes to the fan and insert the components in line to shut the fan off according to temperature.

So here's what you need to add just the fan shutdown feature:

-Spring wound timer switch, like for a bathroom fan or whatever. $20

-Functional Devices RIB RIB1UC SPDT relay. $20

-TET7100, JLD7100, D1S-2R-200 'PID Temperature Controller'. Be sure to find one that includes a K-Type thermocouple, or order one separately. $50

If you want to be able to ride out a power failure, then the timer needs to have a long enough range that you can set it to run until plenty of the wood is gone. If the power fails after the timer runs out, and the flue cools off, then the fire stays out until you restart it, oh well.

Normally the thermocouple should go in the flue neck. If the flue cools off because the boiler idles then burn will be complete at that time, tanks are hot, call it a day. I drilled a hole along the top of a horizontal section and screwed the thermocouple into it, with a little piece of rock wool around the lead to improve accuracy. Shutoff at 285 degF is working for me, temperature setting doesn't seem to be critical as long as it's substantially less than cruising temperature.

It's nice to prevent blowing cold air through your boiler and up the flue after the fire has burnt out, but what's really nice is that you can shut the burn down while there's plenty of charcoal left to start the next burn. This works great, just rake the charcoal over the nozzle, start it glowing with literally a few seconds of propane flame, place a couple of splits flat on top of the charcoal and walk away.

[Yes, I know I misspelled 'controler'.]

Cheers --ewd

First consider the 'Garth B' solution. Wiring 120VAC over to a hot flue and back might be a little dodgey but it's nice and simple.

https://www.hearth.com/econtent/index.php/forums/viewthread/80894/P15/#973718

[quote author="Garth B" date="1319066537"]I installed an adjustable snapdisc (18$) on the flue and wired it in paralel with a timer which are both in series with a lightswitch and the fan on my econoburn. Have been set up like this for 2 years and has been working great. I start a fire, turn the timer to 15-20min which gives the flue gas time to heat up and close the snapdisc, then when the flue gas drops below 150 it shuts the fan down. The lightswitch shuts the fan down while I load wood so I dont have to shut the boiler and circ pump off with the main switch. I will be posting pics soon[/quote]

]

The topic comes up from time to time and is currently being discussed elsewhere.

My boiler control includes end of burn draft fan shutdown, but my control also has to control everything else as well since my RK2001U went tango uniform. This is confusing, and so it's not the best example if all a guy wants is just the draft fan shutdown feature.

What you do is take the hot wire that goes to the fan and insert the components in line to shut the fan off according to temperature.

So here's what you need to add just the fan shutdown feature:

-Spring wound timer switch, like for a bathroom fan or whatever. $20

-Functional Devices RIB RIB1UC SPDT relay. $20

-TET7100, JLD7100, D1S-2R-200 'PID Temperature Controller'. Be sure to find one that includes a K-Type thermocouple, or order one separately. $50

If you want to be able to ride out a power failure, then the timer needs to have a long enough range that you can set it to run until plenty of the wood is gone. If the power fails after the timer runs out, and the flue cools off, then the fire stays out until you restart it, oh well.

Normally the thermocouple should go in the flue neck. If the flue cools off because the boiler idles then burn will be complete at that time, tanks are hot, call it a day. I drilled a hole along the top of a horizontal section and screwed the thermocouple into it, with a little piece of rock wool around the lead to improve accuracy. Shutoff at 285 degF is working for me, temperature setting doesn't seem to be critical as long as it's substantially less than cruising temperature.

It's nice to prevent blowing cold air through your boiler and up the flue after the fire has burnt out, but what's really nice is that you can shut the burn down while there's plenty of charcoal left to start the next burn. This works great, just rake the charcoal over the nozzle, start it glowing with literally a few seconds of propane flame, place a couple of splits flat on top of the charcoal and walk away.

[Yes, I know I misspelled 'controler'.]

Cheers --ewd