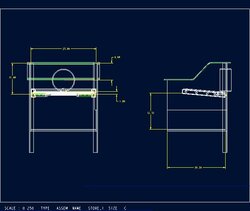

Happy New Year Hearth Members. Here's the official debut of my stove modifications. I got my Englander 12 two years ago and with some time and knowledge from this site I learned to burn it better, mostly over coming the air control sloppiness issues with this "35 t0 1" non EPA model, basically operating it with the efficiency of a smoke dragon. That was all well and good but I yearned for more from it, and being a true caveman, I wanted the ultimate light show that only secondary combustion provides. So, inspired by the Youtube Elm stove guy I got to work hot rodding the ol' 12. Since I didn't know how well it would respond to modification I didn't want to do a lot of permanent damage to the stove, so looking back there are a few things I could have done easier and cheaper but I can't ague with the results. I got most supplies from McMaster/Carr (www.mcmaster.com). Due to the inside architecture of the 12, I was limited to where I could put the burn tubes and baffle. There's a steel plate 3 inches wide just inside the door so I drilled the holes for the tubes so the baffle, when mounted on top, would be level with that plate. I used a baffle from a 13NC cut and trummed to fit the contours of the 12, leaving about and inch between the baffle and steel plate for the smoke to escape. For burn tubes I used 1/4" stainless pipes (actually measures 1/2 OD) held together in the middle with couplers as they didn't have a single pipe that was just the right length. A 10" section mated to an 11"' section. I also put couplers on the ends.(see pics) I drilled 3/16 holes in the tubes and angled the tubes as described in the 13nc manual. I used 1/8 to 1/4" reducers ( again, not actual size but rather just the strange "pipe lingo") to secure the pipes through the sides of the stove. I tried running it this way with the pipes just drawing room temp air through the sides of the stove and got some secondary action but they weren't sustainable. So, due to limited space inside the 12, I had to fab up some external manifolds. (see pics) I wanted to make it look as unobtrusive as possible so I fabbed them to mimic the air control unit on the front. I used 2 peices of 1" square tubing per side. Drilled a hole near both ends of on one side of each suare tube and then stacked the tubes so the holes lined up. I then capped the ends with steel bar stock and welded the tubes together.I then drilled holes to line up with the holes in the stove for the stainless pipe and access holes on the opposite side to get my ratchet in there (see pics). I used the reducer to secure the manifolds and pipes (see pics) There's a hole drilled in the bottom center of each manifold where air is drawn in, runs to the ends of the lower section and then travels to the uppersection, through the reducers and into the pipes inside the stove. The results are pretty wild. Max stove top temps before the mods, with the stove packed to the cieling with seasoned wood and running wide open was 550*. Max now with not quite fully seasoned wood loaded just above fire bricks is 660* with air control 3/4 closed. I even achieved a max temp of 550* with air closed as far as it could go with only a half load of VERY VERY dry wood. I'd say the experiment was a success. It's taken quite a bit of trial and error to achieve results and as you all know there's a different prcedure to be used with different variables: outside temps, wood type, size and loading arrangement. Just out of curiosity, I'm considering provisions for "Zipper air" and perhaps one more burn tube mounted below the steel plate in front and facing rearward. It's been a blast playing with this thing and I've lingered by the stove many a night past my bedtime watching "Caveman TV" in all it's secondary burning splendor. Speaking of secondary splendor, check out the pictures. I'll include as many as I can in this post and then post some more.

Attachments

-

stove mods 3.jpg44.3 KB · Views: 1,713

stove mods 3.jpg44.3 KB · Views: 1,713 -

stove mods 1.jpg54.4 KB · Views: 1,730

stove mods 1.jpg54.4 KB · Views: 1,730 -

stove mods 2.jpg24.4 KB · Views: 1,733

stove mods 2.jpg24.4 KB · Views: 1,733 -

stove mods 4.jpg29.1 KB · Views: 1,734

stove mods 4.jpg29.1 KB · Views: 1,734 -

sec burn 4.jpg29.5 KB · Views: 1,670

sec burn 4.jpg29.5 KB · Views: 1,670 -

northern lights.jpg30 KB · Views: 1,680

northern lights.jpg30 KB · Views: 1,680 -

sec burn 5.jpg15.6 KB · Views: 1,681

sec burn 5.jpg15.6 KB · Views: 1,681 -

sec burn 7.jpg30.7 KB · Views: 1,555

sec burn 7.jpg30.7 KB · Views: 1,555

She doesn't know what "cat" is short for. But, yeah, I thought about the possibilty of going with a cat the other day. The inside architecture would actually lend itself well to that idea as theres a 6" x 9"ish opening in the upper structure. It was a pasing thought though. I'm happy with the burn tube technology and like I said, I REALLY dig the light show.

She doesn't know what "cat" is short for. But, yeah, I thought about the possibilty of going with a cat the other day. The inside architecture would actually lend itself well to that idea as theres a 6" x 9"ish opening in the upper structure. It was a pasing thought though. I'm happy with the burn tube technology and like I said, I REALLY dig the light show.