Hello

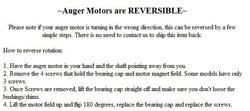

The 1st problem was the top auger quit after a couple hours.

Well after getting the knit line ground down on the top auger it turns freely now and runs longer.

See > Englander 25-PDV - Drop Chute Jam

https://www.hearth.com/talk/threads/englander-25-pdv-drop-chute-jam.85348/

Now the top Auger runs about a day and then stops. The bottom auger is starved of pellets and then the fire goes out.

I wiggled the top auger, it did not feel stuck this time. After touch it and moving it the auger started up again. The same thing happened when testing with the line cord. So now it is an electrical connection.

Then I was refered to the thread on Merkle Korff and Gleason - Avery brand comparison.

https://www.hearth.com/talk/threads/englander-auger-motor-failure-and-replacement.30454/

It also pointed out that the older MK motors were crimped and not soldered.

See my pics which show the wire (See yellow arrow) from the transform being pinched under the tab to hold it in place.

I know from working with Hewlitt-Packard once in their Medical Products division that in order to make a good quality device, there must be a good phsical connection and a good electrical connection!

Electrical Connections are points where many failures occur. An auger wire connection being exposed to vibration and expansion and contraction from heat is a very vulnerable connection!

So since the motor itself seems good, I will clean and solder these connections and try running the stove again!

The 1st problem was the top auger quit after a couple hours.

Well after getting the knit line ground down on the top auger it turns freely now and runs longer.

See > Englander 25-PDV - Drop Chute Jam

https://www.hearth.com/talk/threads/englander-25-pdv-drop-chute-jam.85348/

Now the top Auger runs about a day and then stops. The bottom auger is starved of pellets and then the fire goes out.

I wiggled the top auger, it did not feel stuck this time. After touch it and moving it the auger started up again. The same thing happened when testing with the line cord. So now it is an electrical connection.

Then I was refered to the thread on Merkle Korff and Gleason - Avery brand comparison.

https://www.hearth.com/talk/threads/englander-auger-motor-failure-and-replacement.30454/

It also pointed out that the older MK motors were crimped and not soldered.

See my pics which show the wire (See yellow arrow) from the transform being pinched under the tab to hold it in place.

I know from working with Hewlitt-Packard once in their Medical Products division that in order to make a good quality device, there must be a good phsical connection and a good electrical connection!

Electrical Connections are points where many failures occur. An auger wire connection being exposed to vibration and expansion and contraction from heat is a very vulnerable connection!

So since the motor itself seems good, I will clean and solder these connections and try running the stove again!