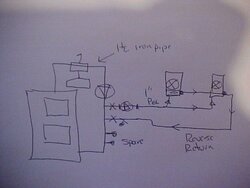

I'm just looking to only make heat in the insulated pole barn where the EKO is located. Can I get by with 1 Taco 007, 15 PSI pressure relief, air remover, danfoss (boiler return protection) and pipe a simple loop with 2 small unit heaters (water to air exchangers with fan, Modine looking type but not Modines). The EKO will idle some because the heaters will probably only pull about 25K BTU each. How far must I use black iron or copper? I may keep these heaters close to the EKO on the floor and was hoping to utilize some Pex. My interior walls (OSB) are up but I left some of them tacked loose to allow for wiring (after I can get some heat going) so I probably won't mount anything permanent until this heating season is over. New home should be done in April or May and will have to trench lines to it later after the builder is long gone but before we landscape. Just need a simple way to get some heat going right now. Next short term plans include sidearm with electric (or maybe propane) water heater for DHW in the pole barn but also to serve as freeze protection and UPS/deep cycle power loss protection. If anybody has a simple drawing that would be great or maybe just some do's and don'ts. Am I better off sticking a used woodstove in as a temp solution? I was hoping a simple loop would only take a day or two to assemble.

Example of the simplest EKO piping install

- Thread starter husker

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.