Hello All.

So my install is finally about to go somewhere. Hurrah!

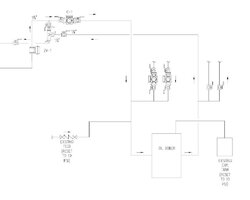

I had my installer over today to talk shop, and he was looking over my schematics, and my existing system. Turns out to pipe this up the way I have drawn, that really involves taking apart all of my existing near-boiler piping and re-doing all of it. This is not what I was hoping for, but I think I also turned a blind eye to it in the hopes that this wouldnt be the case. Just proves that ignoring something does not make it go away.

At any rate, what he was proposing was to utilize a set of tappings on the oil boiler to flow my water from storage through this boiler and then back to storage when there is a call for heat. This way the configuration of my zones and circs wont have to change, and it gets me out much cheaper as far as labor goes.

I know keeping more iron hot is going to cost me efficiency, and there will be some heat loss out the chimney this way, but does anyone have any idea what kind of losses this would create? Im trying to determine if I want to bite the bullet and have it all re-piped, or if I want to just flow through the OB and be happy. Both will work, just the engineer in me wants it to look like the perfect schematic.

Thoughts?

So my install is finally about to go somewhere. Hurrah!

I had my installer over today to talk shop, and he was looking over my schematics, and my existing system. Turns out to pipe this up the way I have drawn, that really involves taking apart all of my existing near-boiler piping and re-doing all of it. This is not what I was hoping for, but I think I also turned a blind eye to it in the hopes that this wouldnt be the case. Just proves that ignoring something does not make it go away.

At any rate, what he was proposing was to utilize a set of tappings on the oil boiler to flow my water from storage through this boiler and then back to storage when there is a call for heat. This way the configuration of my zones and circs wont have to change, and it gets me out much cheaper as far as labor goes.

I know keeping more iron hot is going to cost me efficiency, and there will be some heat loss out the chimney this way, but does anyone have any idea what kind of losses this would create? Im trying to determine if I want to bite the bullet and have it all re-piped, or if I want to just flow through the OB and be happy. Both will work, just the engineer in me wants it to look like the perfect schematic.

Thoughts?