A couple tips, yes you can remote mount the expansion tank. If you use multiple tanks, tee them in at the same location. The best location is the suction side of the system pump. If you have multiple pumps selecting the best location is trickier.

Always mount the tank with the connection nipple pointing up to prevent any O2 from corroding the thin steel tank. Most tanks are bladder tanks and contain the fluid in the steel vessel. there are some bag type that contain the liquid inside the bladder membrane. With the fluid in the steel part of the tank it can cool better, this is more critical on solar piping where the tank can see a shot of temperatures in excess of 300F after a stagnation condition.

Remote mounting the tank can add the benefit of cooling the liquid the tank sees during heating, to prevent reducing the capacity due to the warmed fluid.

If you mount the tank below the connection point a fair distance remember the static pressure increases and the tanks expansion volume will be slightly decreased. Many installers build a unistrut rack system above the boiler to mount multiple small tanks. A base mounted tank is another option, it's connection point is usually at the bottom of the tank. Installers often use pex tube to pipe to remote tanks.

Check the air charge in the tank BEFORE you fill and pressurize the system. It should be pressurized to within a few pounds of what you intend to pressurize the system to, generally 12- 15 psi for a one or two story home. You want a few pounds static pressure at the highest point in the piping system.

If you do install an isolation valve on the tank(s) I'd remove the handle so it does not get turned off by mistake. There are some special expansion tank valves on the market. Some are dual checks, some have a lockable shut off handle.

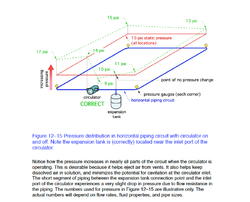

Here is a drawing from Modern Hydronic Heating 3rd edition. A great book to own if you want to learn the fine points of hydronic design and piping

www.hydronicpros.com The drawing clearly shows how pumping away from the expansion tank connection point behaves in the piping and pressure.

hr