Folks its nearing the end of the wood burning season for me and this being my first winter with hydronic system installed I have a few questions for over the summer adjustments. My system did very well this winter heating 5000 sq ft and dhw. My neighbor and I did the install and thanks to this board did not spend a penny on labor.

A few questions:

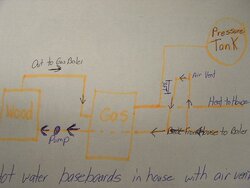

I have a conventional indoor wood boiler that is piped into a gas boiler and then on into the house. The propane boiler was there when I bought the house so I decided to pipe them together in the event I would need it when away. My wood boiler outflow to the propane boiler comes out of the top of the wood boiler travels horizontal for 3 feet then turns straight down about 3 feet to go into the propane boiler. It then leaves the propane boiler, goes to a tee (1/2 copper goes vetical to expansion tank, 1 inch copper goes horizontal into the house for heat.)

I'm getting some air trapped in the propane boiler because everyday I can lift the popoff valve on the propane and get air for about 2 seconds.

My question is this. Should my expansion tank which is a 45 gallon solid tank be teed into my wood boiler outflow before it turns down to go in the propane boiler? I'm thinking this will fix my air problem and since my wood boiler is my primary heat it should be this way anyhow.

Will this affect my propane boiler operation. I do not run them together it is either one or the other and it will be rare that I run propane.

I did not have any pressure problems the entire winter but the air should not be getting caught in the propane boiler

A few questions:

I have a conventional indoor wood boiler that is piped into a gas boiler and then on into the house. The propane boiler was there when I bought the house so I decided to pipe them together in the event I would need it when away. My wood boiler outflow to the propane boiler comes out of the top of the wood boiler travels horizontal for 3 feet then turns straight down about 3 feet to go into the propane boiler. It then leaves the propane boiler, goes to a tee (1/2 copper goes vetical to expansion tank, 1 inch copper goes horizontal into the house for heat.)

I'm getting some air trapped in the propane boiler because everyday I can lift the popoff valve on the propane and get air for about 2 seconds.

My question is this. Should my expansion tank which is a 45 gallon solid tank be teed into my wood boiler outflow before it turns down to go in the propane boiler? I'm thinking this will fix my air problem and since my wood boiler is my primary heat it should be this way anyhow.

Will this affect my propane boiler operation. I do not run them together it is either one or the other and it will be rare that I run propane.

I did not have any pressure problems the entire winter but the air should not be getting caught in the propane boiler