Experimental passive solar wood kilns

- Thread starter Poindexter

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

firefighterjake

Minister of Fire

Seems like some folks go to a lot of time, effort and money to season their wood faster . . . and in some cases I wonder why they just don't give the wood time . . . but in other cases (such as this) I can understand somewhat when one lives in an area where just leaving the wood outside for a year or two might not be all that beneficial.

I got the fool thing up on my skiff trailer today - thank God for boat trailer winch systems. It settled back out to flat and square in about two hours.

I went ahead and put the rest of the rafters up just to get them off the garage floor.

So I got a few options at this point. The wife suggested we sell the five bedroom house, it's just the two of us and the cat one of the kids left behind. We are bringing all our food and all our cordwood up a flight of stairs we don't need.

Talked to the realtor, experimental solar kilns should be negotiable and portable, if they work good they won't hurt the property value, but still portable is better.

So one option is to sink 4 post holes into frozen dirt, 36" deep, 12" diameter, 4x4 posts, crushed rock fill, yada yada yada, holy cow. Four holes per module, seven modules, ain't happening.

The other option is to upgrade the floor framing to not wrack on an 8 foot span when filled to 4000# and one pier block is low.

2x8 PT floor framing is a possibility. Another option is 2 pieces of 4x6 as runners, connected with a 2x6 box down the middle.

I could build either of those, floor it, then move all the 2x4 off the existing floor as one unit, then re-use the plywood left behind on the next unit- leaving the existing PT 2x4 as scrap. This is probably the best option. @5.67 each I would be scrapping about 30 bucks to save the other $270.

Last option is get a pair of PT 4x4s, eight footers. Set those on pier blocks at the corners, do what I have to do for shimming, set the entire assembly I have on the 4x4s and then run some lag bolts in while everything is square.

Stewing, but I need to get cracking on this, it is almost Christmas and I don't have a single split put up for next winter. I am about two cords behind on splitting and stacking.

I went ahead and put the rest of the rafters up just to get them off the garage floor.

So I got a few options at this point. The wife suggested we sell the five bedroom house, it's just the two of us and the cat one of the kids left behind. We are bringing all our food and all our cordwood up a flight of stairs we don't need.

Talked to the realtor, experimental solar kilns should be negotiable and portable, if they work good they won't hurt the property value, but still portable is better.

So one option is to sink 4 post holes into frozen dirt, 36" deep, 12" diameter, 4x4 posts, crushed rock fill, yada yada yada, holy cow. Four holes per module, seven modules, ain't happening.

The other option is to upgrade the floor framing to not wrack on an 8 foot span when filled to 4000# and one pier block is low.

2x8 PT floor framing is a possibility. Another option is 2 pieces of 4x6 as runners, connected with a 2x6 box down the middle.

I could build either of those, floor it, then move all the 2x4 off the existing floor as one unit, then re-use the plywood left behind on the next unit- leaving the existing PT 2x4 as scrap. This is probably the best option. @5.67 each I would be scrapping about 30 bucks to save the other $270.

Last option is get a pair of PT 4x4s, eight footers. Set those on pier blocks at the corners, do what I have to do for shimming, set the entire assembly I have on the 4x4s and then run some lag bolts in while everything is square.

Stewing, but I need to get cracking on this, it is almost Christmas and I don't have a single split put up for next winter. I am about two cords behind on splitting and stacking.

Looked my options over pretty hard.

I know from experience I can stack a green cord, ~4000#, on two pallets up on cinder blocks. It will hold, until one of the pallets splits at the side cut out for the lifting forks.

How much is 4000#? A green cord you say, but that is like 2000 pieces at 2 pounds each. How much is it in heavy things? Upright pianos go 300 to 800 pounds each according to google, the Steinway model D, a nine foot concert sized grand piano, is 990#. Now it seems real. 4000# on a 42x96" footprint (28.5 sqft) is like piling eight upright pianos, or four 9 foot concert grands on one module.

4000#/ 28.5 sqft is 140# per sqft. Residential homes are generally built for 40# per sqft, no pile of pianos is going to work in any house I ever lived in. Light industrial floors are generally accepted to handle 125# sqft; heavy industrial floors, 150# sqft. So I need a heavy industrial floor.

I thought about the homes I have visited built on permafrost, where they do the three foot deep holes with compacted gravel - for 40#/ sqft loading- and most of them have the twisty jacks permanently installed on all the posts so the homeowner can go relevel the floor every spring and fall.

I remember in Kentucky the frost line was at 24", mostly because all the fence post holes I dug had to be 30" deep. And in upstate NY the frost line was 42" and all the house footings had to be 48" deep. And the houses up here on 36" posts move around even at 40# per sqft.

So I accept no matter what I do, the piers my modules sit on are going to move around. I just have to allow for that. Then I googled up random stuff like "Why does my deck bounce when my guests get liquored up?"

I know from experience I can stack a green cord, ~4000#, on two pallets up on cinder blocks. It will hold, until one of the pallets splits at the side cut out for the lifting forks.

How much is 4000#? A green cord you say, but that is like 2000 pieces at 2 pounds each. How much is it in heavy things? Upright pianos go 300 to 800 pounds each according to google, the Steinway model D, a nine foot concert sized grand piano, is 990#. Now it seems real. 4000# on a 42x96" footprint (28.5 sqft) is like piling eight upright pianos, or four 9 foot concert grands on one module.

4000#/ 28.5 sqft is 140# per sqft. Residential homes are generally built for 40# per sqft, no pile of pianos is going to work in any house I ever lived in. Light industrial floors are generally accepted to handle 125# sqft; heavy industrial floors, 150# sqft. So I need a heavy industrial floor.

I thought about the homes I have visited built on permafrost, where they do the three foot deep holes with compacted gravel - for 40#/ sqft loading- and most of them have the twisty jacks permanently installed on all the posts so the homeowner can go relevel the floor every spring and fall.

I remember in Kentucky the frost line was at 24", mostly because all the fence post holes I dug had to be 30" deep. And in upstate NY the frost line was 42" and all the house footings had to be 48" deep. And the houses up here on 36" posts move around even at 40# per sqft.

So I accept no matter what I do, the piers my modules sit on are going to move around. I just have to allow for that. Then I googled up random stuff like "Why does my deck bounce when my guests get liquored up?"

The wall system I have already built more or less requires a flat floor. Doesn't have to be perfectly level, but it can't twist or my wood is coming down.

So I built a new box in 2x10 to the same dimensions as the original one in 2x4.

Then I put skids on what will be the bottom...

I am using "uber grade" screw fasteners by some company with a TLA for a name. It was the only PT fastener I could find (HD only, not Lowes) that lists a shear rating on the packaging. They are about 12 cents each when buying in bulk. I was thinking of a certain brick house, screws are rated for 1012# shear.

Then I flipped it over and put in a central line of stiffeners...

I did the plastic vapor barrier and plywood flooring as previously documented and got the existing wall system moved over just before sundown.

So I built a new box in 2x10 to the same dimensions as the original one in 2x4.

Then I put skids on what will be the bottom...

I am using "uber grade" screw fasteners by some company with a TLA for a name. It was the only PT fastener I could find (HD only, not Lowes) that lists a shear rating on the packaging. They are about 12 cents each when buying in bulk. I was thinking of a certain brick house, screws are rated for 1012# shear.

Then I flipped it over and put in a central line of stiffeners...

I did the plastic vapor barrier and plywood flooring as previously documented and got the existing wall system moved over just before sundown.

At this point I am over budget like a shameless defense contractor.

I am going to keep the original 2x4 framed floor module, the one up on the trailer above. I am going to put a different wall and roof system on it that allows for it to twist as the ground thaws and my cinder blocks move.

I am going to keep the original 2x4 framed floor module, the one up on the trailer above. I am going to put a different wall and roof system on it that allows for it to twist as the ground thaws and my cinder blocks move.

therdlesstravld

Member

Just a tip for the future. Nails have a much higher shear rating than screws for the most part. Your Home Depot should have Simpson brand strong nails which is what we use for deck fasteners and hangers.

Hangers would also increase the strength of everything. You could use regular framing screws or nails for everything except the floor joists. And then hang the joists on 2x10 joist hangers directly into a doubled up rim joist. Use longer Simpson nails for the hangers so they go into the second rim joist and you've got something.

Hangers would also increase the strength of everything. You could use regular framing screws or nails for everything except the floor joists. And then hang the joists on 2x10 joist hangers directly into a doubled up rim joist. Use longer Simpson nails for the hangers so they go into the second rim joist and you've got something.

Just a tip for the future. Nails have a much higher shear rating than screws for the most part. Your Home Depot should have Simpson brand strong nails ...directly into a doubled up rim joist. Use longer Simpson nails for the hangers so they go into the second rim joist and you've got something.

Duly noted.

I have a quote floating around my workshop I wanna share. I wish I had read this a few years earlier. I am about to build a module to sit on moving ground to carry a cord of wood, with a floating roof on it.

A. Donald Newell said:Chapter one: Do not think you are limited by what you have to work with. You are limited only insofar as you allow your intelligence and reasoning to do that limiting. Accept a narrow horizon and your work will reflect that thought, but by realization of the vast possibilities open to you your scope of operations will be broadened and your work will reflect that freedom of thought and action.

How cool is that? I wish I had read it 20 years earlier.

_Guide to Gunstock Finishing and Care_, A. Donald Newell, (c. 1949)

I did add two more pieces of framing while I had the thing apart, see esp posts 41 and 43, the new pair still has the tags on it:

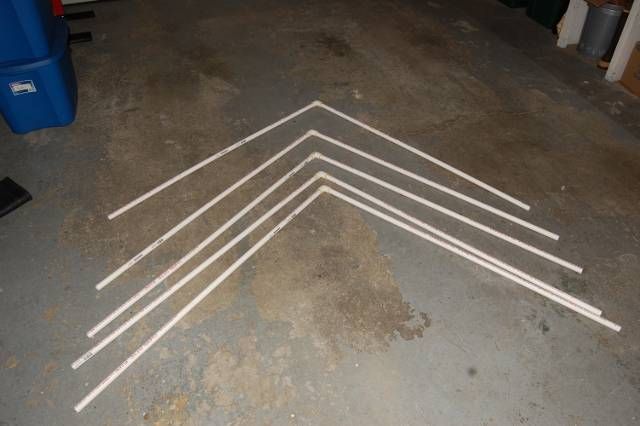

I originally bent all the middle section PVC hoops by taking one of the corner hoops off, bending to the same curve - but the middle pieces relaxed into a slightly different shape. The added piece seems to be a success at holdign the same curve over the length of the unit.

I did get the plastic up tonight, fairly long handheld exposure with a flashlight inside the kiln:

And I did get four pieces put up for winter of 16/17. I was beginning to think I wasn't gonna have any wood put up for next winter when New Year's got here. Squeaked under the wire on that one, thanks to a branch coming down in my neighbor's yard.

Only 13,996 pieces of firewood to go to be ready for next winter.

At this point I have almost everything I need to finish a second module, and likely off work on Wednesday. I just can't hardly bear to calculate how much I have spent on this one, though it should last the rest of my life except for the plastic and maybe a PVC pole or three.

I originally bent all the middle section PVC hoops by taking one of the corner hoops off, bending to the same curve - but the middle pieces relaxed into a slightly different shape. The added piece seems to be a success at holdign the same curve over the length of the unit.

I did get the plastic up tonight, fairly long handheld exposure with a flashlight inside the kiln:

And I did get four pieces put up for winter of 16/17. I was beginning to think I wasn't gonna have any wood put up for next winter when New Year's got here. Squeaked under the wire on that one, thanks to a branch coming down in my neighbor's yard.

Only 13,996 pieces of firewood to go to be ready for next winter.

At this point I have almost everything I need to finish a second module, and likely off work on Wednesday. I just can't hardly bear to calculate how much I have spent on this one, though it should last the rest of my life except for the plastic and maybe a PVC pole or three.

sportbikerider78

Minister of Fire

I have given up on nails entirely. I love the deck style screws that you install using an impact. They are absolute heaven when you can't get access to an area or you are working over your head. I'll never buy normal phillips head screws again.

kennyp2339

Minister of Fire

Those coated deck screws with the star heads have a higher sheer resistance than normal house screws, they are a life saver, I remember the old say: nail things up, screw things down.I have given up on nails entirely. I love the deck style screws that you install using an impact. They are absolute heaven when you can't get access to an area or you are working over your head. I'll never buy normal phillips head screws again.

sportbikerider78

Minister of Fire

Oh yeah. I would never use sheetrock screws for an outdoor project I cared anything about. They will rust through in a short period of time. They are SUPER cheap, but find for their designed purpose.

Ashful

Minister of Fire

Deck screws are for decking. Timberlocks are the way to go with framing. Available in all sizes, even countersunk head with serrated teeth under the head for self-sinking, and they're all rated for very high sheer.

That said, I nail a lot more framing today than I used to, ever since buying a real framing nailer. Much quicker than screws with the impact driver.

That said, I nail a lot more framing today than I used to, ever since buying a real framing nailer. Much quicker than screws with the impact driver.

Random pic I clicked on in my camera when I was downloading the day's work. Looks like June, I had one corner of one pallet crack, about two cords of wood on the ground in 5-6 seconds. This is why I HATE stacking cordwood on pallets. Do notice the cinderblocks...

Work space of the day is this cavity, four pallets long. The upright two cinder blocks on the far right have been moved, all the other cinder blocks just peeking out of the snow have been load bearing for at least one year and not likely to move very much.

I cut 24" off of each of four 2x4s and built two boxes with outside dimensions 24x75". I'll get back to that pallet laying there in a couple weeks.

For ridgepole holders, 2 8 foot 2x4s with some pretty cheap work at the top end.

Assembled the framing looks like this, the first floor I built on well settled cinderblocks, likely to sag 1/4" in the middle, boxes and ridge supports as above, two more 8 foot 2x4s accross the top, think of a bunk bed. If i can fit a layer of 16" splits up there 5.5" high then this module will hold one green cord.

This thing is barely pinned together, just strong enough to support the roof. Needs a diagonal system to keep it square, and I am going to have a tussle stacking in it.

I used rope, bowlines and Spanish Windlasses for the diagonals.

Work space of the day is this cavity, four pallets long. The upright two cinder blocks on the far right have been moved, all the other cinder blocks just peeking out of the snow have been load bearing for at least one year and not likely to move very much.

I cut 24" off of each of four 2x4s and built two boxes with outside dimensions 24x75". I'll get back to that pallet laying there in a couple weeks.

For ridgepole holders, 2 8 foot 2x4s with some pretty cheap work at the top end.

Assembled the framing looks like this, the first floor I built on well settled cinderblocks, likely to sag 1/4" in the middle, boxes and ridge supports as above, two more 8 foot 2x4s accross the top, think of a bunk bed. If i can fit a layer of 16" splits up there 5.5" high then this module will hold one green cord.

This thing is barely pinned together, just strong enough to support the roof. Needs a diagonal system to keep it square, and I am going to have a tussle stacking in it.

I used rope, bowlines and Spanish Windlasses for the diagonals.

On to the floating roof...

I want them all to come out the same since I have 20 some more hoops to go after these five...

I want them all to come out the same since I have 20 some more hoops to go after these five...

So I got room for a full cord in here, the chunk of furring strip acting as a spreader is 17.25" long and 11" above the deck of the bunk bed.

The ridgepole is a 1x3 furring strip, just laid up there between the screws I pictured earlier. I am going to tie some 550 cord around the ridge pole at each end, and then through the holes I drilled in the verticals so the roof doesn't blow away in a strong wind.

Gonna go have another beer while I stare at it some more...

The ridgepole is a 1x3 furring strip, just laid up there between the screws I pictured earlier. I am going to tie some 550 cord around the ridge pole at each end, and then through the holes I drilled in the verticals so the roof doesn't blow away in a strong wind.

Gonna go have another beer while I stare at it some more...

Yup, I think it will work. Instead of q8 of PT 2x10s I am going for q4 of 1x3 furring strips tomorrow.

It has occurred to me I could register a homebuilt 16' x 42" johnboat with the state, use a veiner bit on my router to engrave the registration number on the two expensive ones (only one is built right now), and have a leg to stand on if they are ever found.

It has occurred to me I could register a homebuilt 16' x 42" johnboat with the state, use a veiner bit on my router to engrave the registration number on the two expensive ones (only one is built right now), and have a leg to stand on if they are ever found.

kennyp2339

Minister of Fire

Ashful

Minister of Fire

Why would you put cinder blocks under your pallets? Of course they're going to fail, if you do that! The reason we use pallets is that they give a 3.5" air space below the cord wood, even when placed directly on the ground. No need for cinder blocks.Random pic I clicked on in my camera when I was downloading the day's work. Looks like June, I had one corner of one pallet crack, about two cords of wood on the ground in 5-6 seconds. This is why I HATE stacking cordwood on pallets. Do notice the cinderblocks...

View attachment 170436

If your ground isn't level, then just shim the low spots with pavers, brick, or scrap wood. Try to get one under the middle, and at least three down the elevated edge, or they'll fail, as you found. Pallets are designed to carry substantial weight, when placed on continuous level ground.

Why would you put cinder blocks under your pallets?

Well, how long have you got? The short version is, like solarguy2003, I am in a running battle with ground water at my address.

I started out with pallets directly on the ground.

My wood got "dry", but nothing spectacular, and then that same wood picked up a bunch of water every time ambients got above freezing.

Three of the last five years we get 5-7 days around Thanksgiving with daytime highs at like +40dF and then back below freezing overnights. With pallets on the ground, I would have melting snow running downhill into my dry wood, and early in the burning season too. The hard packed snow I have been walking on to get to my woodpile is a layer thicker than the cinder blocks are tall. Off the packed trails, the snow in my yard is midthigh deep, about 30" accumulated.

We hit +40dF yesterday, 12-30-15. Nice to be out there working in shirtsleeves, but as above, wood on pallets... Never seen that in December before.

December anomaly aside, the other annual event is the melt. Long about mid March I'll be seeing consistent day time highs above freezing on into summer. I need to have all the wood up by then; because the packed snow on the driveway either gets my attention, or my wife gets my attention about the puddle of icy cold water under the laundry machines.

I'll be running the stove into early May for sure. What I can do in say early April is kneel next to my wood pile, take a glove off my hand, stick my hand in the gap between the snow and the pallet, and my hand will be literally dripping wet with condensation in a matter of seconds on the south side of the stack. Same day, other hand, north side of the stack, I can see little tiny beads of condensation on the skin of my hand in moments.

When my wood pile is 12%MC and there is that much vapor in the air, the vapor is going to end up in my cordwood. I can lift the wood above the worst of the vapor layer, and this year am adding plastic to the underside of my seasoning stacks.

All of the above ignores direct pumping of water out of the ground into the stacks. A dry, hot stack of wood, at my house, will pump water straight out of the ground into itself. I have about a cord put up, completely wrapped in plastic on all 6 sides for the spring 2016 melt. Hopefully it works,

First, i gotta renumber. I was gonna go back and edit all the previous posts, ain't happening.

Working right to left:

The hole in the hardpack with the junk piled in it, far right, is the home of future module one. Second from right, already plastic covered is module two. It is the second floor I built and the first vertical framing, but it is module two now and will remain so until the house sells. The pallet and hole will be future module three, I am going to use two pallets for the floor and I'll get to it when i get to it. Today, fat left, I was working on module four, the first floor I built and second vertical framing design. Five, six and seven will appear later out past the bezel on your monitor to the further left.

Working right to left:

The hole in the hardpack with the junk piled in it, far right, is the home of future module one. Second from right, already plastic covered is module two. It is the second floor I built and the first vertical framing, but it is module two now and will remain so until the house sells. The pallet and hole will be future module three, I am going to use two pallets for the floor and I'll get to it when i get to it. Today, fat left, I was working on module four, the first floor I built and second vertical framing design. Five, six and seven will appear later out past the bezel on your monitor to the further left.

Put the roof framing together in the garage. Weighs maybe 15 pounds, 40' of 1/2 PVC, 48' of 1x3 furring strip, 5 fathoms of 550 cord, 10 2.5" drywall screws and 70 inches of 1" PVC. And 20 of 1 5/8 DWS too, sorry.

It went up no problem.

Two Spanish windlasses at the tips, one at each end:

Had it looking good enough,

for legs.

I used the off cuts from the 1/2" PVC to make some more ventilators. 3 scraps, 2 wire ties, done. I didn't put the pipe clamps on over the one inch pipe sections until it was up. So far very pleased with the T beam style sill plates, I was anticipating having to run at least one, maybe two connectors through the woodpile and then have to stack around them.

Texted with my wood guy yesterday, he said he would call today but didn't. I do want to get the two i have built loaded up to see what I learn from that before i get too carried away building more.

It went up no problem.

Two Spanish windlasses at the tips, one at each end:

Had it looking good enough,

for legs.

I used the off cuts from the 1/2" PVC to make some more ventilators. 3 scraps, 2 wire ties, done. I didn't put the pipe clamps on over the one inch pipe sections until it was up. So far very pleased with the T beam style sill plates, I was anticipating having to run at least one, maybe two connectors through the woodpile and then have to stack around them.

Texted with my wood guy yesterday, he said he would call today but didn't. I do want to get the two i have built loaded up to see what I learn from that before i get too carried away building more.

So my wood guy is maybe coming Wednesday night. I started loading module four, just moving already seasoned wood in the way of building module five, have a few thoughts.

The bunk bed shelf above is brilliant, if I do say so myself. Short ugly twisty pieces that won't stack well, just throw them up top.

I was rocking until I was trying to fit two layers of wood between the Tbeams, which happen to be at exactly eye level darn it.

View from above, I can't do this efficiently with a head lamp, I'll have to finish tomorrow with sunlight.

Pretty crowded in there. I cram every stick I can in there tomorrow and get it covered, at least this wood won't be getting any wetter if we have another mid-winter thaw. Did you guys see the weather map for Christmas day that had the North Pole at +31dF? Whole darn state of Alaska was above freezing except for Southeast and the Aleutians. Easy on the oil bill, but hard on uncovered woodpiles.

For the next one I am going to lengthen the upper cross piece as shown in this primitive use of MSPaint...

I figure if i can make that 2x4 longer at each end I can attach a 2x4 end to end just hanging out there, attach the PVC hoops to it and not keep banging my head on the Tbeams. And i got to modify the plan for module one, it needs an upper shelf capacious enough for a double dose of uglies and twisties.

The bunk bed shelf above is brilliant, if I do say so myself. Short ugly twisty pieces that won't stack well, just throw them up top.

I was rocking until I was trying to fit two layers of wood between the Tbeams, which happen to be at exactly eye level darn it.

View from above, I can't do this efficiently with a head lamp, I'll have to finish tomorrow with sunlight.

Pretty crowded in there. I cram every stick I can in there tomorrow and get it covered, at least this wood won't be getting any wetter if we have another mid-winter thaw. Did you guys see the weather map for Christmas day that had the North Pole at +31dF? Whole darn state of Alaska was above freezing except for Southeast and the Aleutians. Easy on the oil bill, but hard on uncovered woodpiles.

For the next one I am going to lengthen the upper cross piece as shown in this primitive use of MSPaint...

I figure if i can make that 2x4 longer at each end I can attach a 2x4 end to end just hanging out there, attach the PVC hoops to it and not keep banging my head on the Tbeams. And i got to modify the plan for module one, it needs an upper shelf capacious enough for a double dose of uglies and twisties.

At a decision gate, wouldn't mind some input.

From east to west, here is my existing woodpile in the foreground, future home of modules six and seven. That snow piled up on the north side? Wind blown, that whole side of the stack is filled with snow in every gap between every split, I got accumulation in the gap between the parallel stacks. Further back working to the right I have #5 framed up...

Looking from the other end, I have old splits that were holding down plastic top covering in the future home of 1. 2 is standing empty. In the future home of 3 I have some seasoned cord wood off the stack with the worst of the snow brushed off it. 4 is loaded with seasoned wood, well brushed to get the snow off it, but plenty of mold and mildew from a damp summer. And you can just barely see #5 at the far left.

Looking for +30dF tomorrow. I have a solid cord completely wrapped in plastic under my deck, I am hoping it is well enough wrapped that it doesn't pick up any moisture to speak of during the melt. I have another light cord of seasoned moldy wood sealed up in #4. 4 is open at the west end but sealed shut at the east end, the five side is sealed, the three side is open.

Once the melt is going strong, I am going to have to do something to unit four to kill the mold spores in it. I can replace the plastic cheap, I figure a couple or five good sunny days with no rain should kill everything off.

My wood guy isn't coming Wednesday with two cords, he is coming Saturday with one cord. I figure I'll put the new delivery in 2.

Do I keep brushing snow off my moldy splits and contaminating new construction to keep them from getting any wetter, or do I start infilling with new green splits for next winter?

I am inclined to let it ride and fill the new construction with new wood...

Came up with a curtain idea so I can load and unload without a ladder, I'll get materials on my next trip to the store.

An alternative would be to brush off and restack 6 and 7 into 1 and 3, then top and side cover. Did I mention I HATE restacking wood?

From east to west, here is my existing woodpile in the foreground, future home of modules six and seven. That snow piled up on the north side? Wind blown, that whole side of the stack is filled with snow in every gap between every split, I got accumulation in the gap between the parallel stacks. Further back working to the right I have #5 framed up...

Looking from the other end, I have old splits that were holding down plastic top covering in the future home of 1. 2 is standing empty. In the future home of 3 I have some seasoned cord wood off the stack with the worst of the snow brushed off it. 4 is loaded with seasoned wood, well brushed to get the snow off it, but plenty of mold and mildew from a damp summer. And you can just barely see #5 at the far left.

Looking for +30dF tomorrow. I have a solid cord completely wrapped in plastic under my deck, I am hoping it is well enough wrapped that it doesn't pick up any moisture to speak of during the melt. I have another light cord of seasoned moldy wood sealed up in #4. 4 is open at the west end but sealed shut at the east end, the five side is sealed, the three side is open.

Once the melt is going strong, I am going to have to do something to unit four to kill the mold spores in it. I can replace the plastic cheap, I figure a couple or five good sunny days with no rain should kill everything off.

My wood guy isn't coming Wednesday with two cords, he is coming Saturday with one cord. I figure I'll put the new delivery in 2.

Do I keep brushing snow off my moldy splits and contaminating new construction to keep them from getting any wetter, or do I start infilling with new green splits for next winter?

I am inclined to let it ride and fill the new construction with new wood...

Came up with a curtain idea so I can load and unload without a ladder, I'll get materials on my next trip to the store.

An alternative would be to brush off and restack 6 and 7 into 1 and 3, then top and side cover. Did I mention I HATE restacking wood?

Babaganoosh

Minister of Fire

I had a shrink wrap solar kiln that was hitting 140 degrees daily and as high as 165. Guess what. Still grew mold. I'm not sure you are going to be able to get rid of it.

- Status

- Not open for further replies.

Similar threads

- Replies

- 35

- Views

- 7K

- Replies

- 0

- Views

- 2K

- Replies

- 0

- Views

- 2K

- Replies

- 14

- Views

- 2K

- Replies

- 12

- Views

- 2K