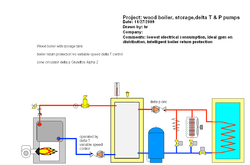

I have been running my system with a delta T function on the boiler pump this season. The control has a data logger built in and I will post some graphs when it runs for a week or so. Nice warm weather has the solar handling the load lately.

With a system piped like this I think you get near ideal operation. The delta T pump on the boiler is ever changing it's speed, and flow rate, based on what the boiler is producing at any given time. So the pump matches the boilers output. It also protect the boiler against cool return temperatures by reving down the rpms (flow rate) as the fire dies, or the load exceeds the boilers output. I notice mine tends to run at 40- 50% speed most of the time. if I let the system and buffer go cold, it will run 100% to catch up. Again based on the return to the boiler.

The tank acts as a buffer and hydraulic separation point. So if for some reason the pump on the system size was larger, or a high head circ, the two pumps will always get along, hydrauliclly speaking.

The distribution circ is a delta P or delta pressure pump. It has power all the time, no need for a relay. When all zones are off it "sleeps" at a 7 watt current draw to keep the electronics and display lite up. If one zone calls, the pump detects the need for additional flow, wakes up and runs about 20W or whatever the zone requires. As additional zones call, the pump speeds up to match this load. This is all calculated inside the electronics built into the pump. It learns, and memorizes you plumbing hydraulics!

The delta P pump, in this case an Alpha 2 by Grundfos is also and ECM (electronically commutated motor). It uses a rare earth magnet design and consumes 40- 60% less energy than a standard circulator doing the same job. So it is possible for you to move a 100K or larger load with 40W of consumption per pump at design conditions. On mild days or light loads the system may be running 20W or less per pump.

So now you have a system with low fuel costs for the energy conversion (wood) and an extremely low electrical consumption with auto adapt pump functions. And return protection without a parastitic device like a 3 way valve, additional piping, etc.

One small downside of this EZ piping is the tank must be maintained at the temperature required to handle all the loads at any given time probably 170- 180 °F for most applications. A 3 way zone valve could be added to bypass storage and feed directly to the loads.

hr

With a system piped like this I think you get near ideal operation. The delta T pump on the boiler is ever changing it's speed, and flow rate, based on what the boiler is producing at any given time. So the pump matches the boilers output. It also protect the boiler against cool return temperatures by reving down the rpms (flow rate) as the fire dies, or the load exceeds the boilers output. I notice mine tends to run at 40- 50% speed most of the time. if I let the system and buffer go cold, it will run 100% to catch up. Again based on the return to the boiler.

The tank acts as a buffer and hydraulic separation point. So if for some reason the pump on the system size was larger, or a high head circ, the two pumps will always get along, hydrauliclly speaking.

The distribution circ is a delta P or delta pressure pump. It has power all the time, no need for a relay. When all zones are off it "sleeps" at a 7 watt current draw to keep the electronics and display lite up. If one zone calls, the pump detects the need for additional flow, wakes up and runs about 20W or whatever the zone requires. As additional zones call, the pump speeds up to match this load. This is all calculated inside the electronics built into the pump. It learns, and memorizes you plumbing hydraulics!

The delta P pump, in this case an Alpha 2 by Grundfos is also and ECM (electronically commutated motor). It uses a rare earth magnet design and consumes 40- 60% less energy than a standard circulator doing the same job. So it is possible for you to move a 100K or larger load with 40W of consumption per pump at design conditions. On mild days or light loads the system may be running 20W or less per pump.

So now you have a system with low fuel costs for the energy conversion (wood) and an extremely low electrical consumption with auto adapt pump functions. And return protection without a parastitic device like a 3 way valve, additional piping, etc.

One small downside of this EZ piping is the tank must be maintained at the temperature required to handle all the loads at any given time probably 170- 180 °F for most applications. A 3 way zone valve could be added to bypass storage and feed directly to the loads.

hr