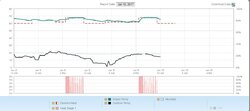

My buffer tank has a mixing valve on it so the return temperature to the boiler can be modified to anything.

The boiler currently running is oil

I had it at 155, now it's at 165. 165 gives 175-180 supply temp.

I figure with baseboard heating, if the boiler is running, 180 will give more heat.

165 setting is filling the buffer tank the same as 155.

I'll probably have to bump it down for the pellet boiler.

Any ideas/opinions on fiddling with return temperature?

(I know there is one person who bumps it up on a Froling wood boiler to get it to modulate.)

The boiler currently running is oil

I had it at 155, now it's at 165. 165 gives 175-180 supply temp.

I figure with baseboard heating, if the boiler is running, 180 will give more heat.

165 setting is filling the buffer tank the same as 155.

I'll probably have to bump it down for the pellet boiler.

Any ideas/opinions on fiddling with return temperature?

(I know there is one person who bumps it up on a Froling wood boiler to get it to modulate.)

.

.