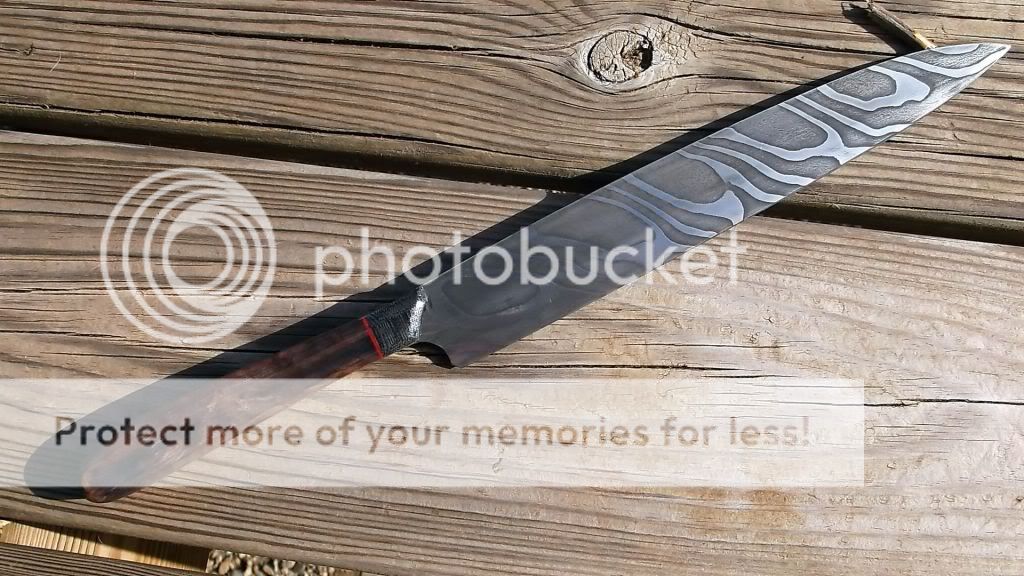

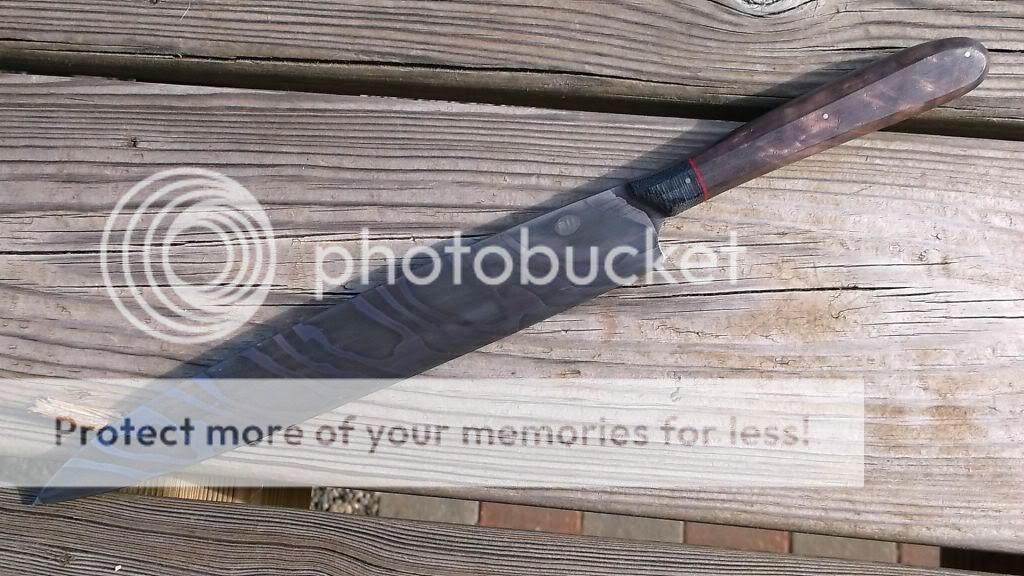

Took me forever to decide what to use for handle scales on this one but I finally decided to go with a piece of highly figured walnut I had at the shop and a little black canvas for bosters with a red liner to set it off. I also started a smaller version to complete the set. I may be obsessed?!?

Now all I need to do is go catch a tuna

Now all I need to do is go catch a tuna

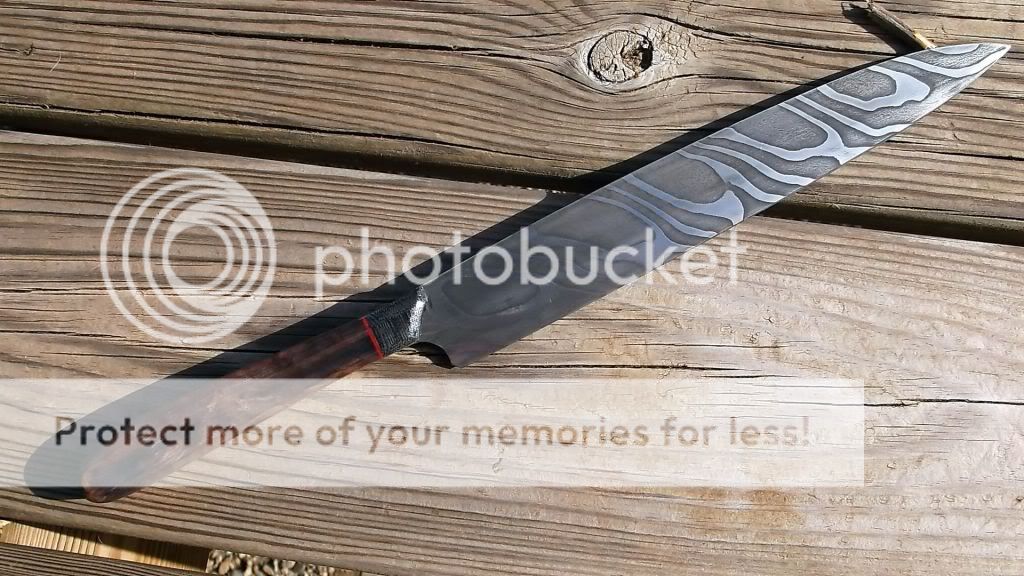

It would probably give me the same feeling as the first door dent in a new car.

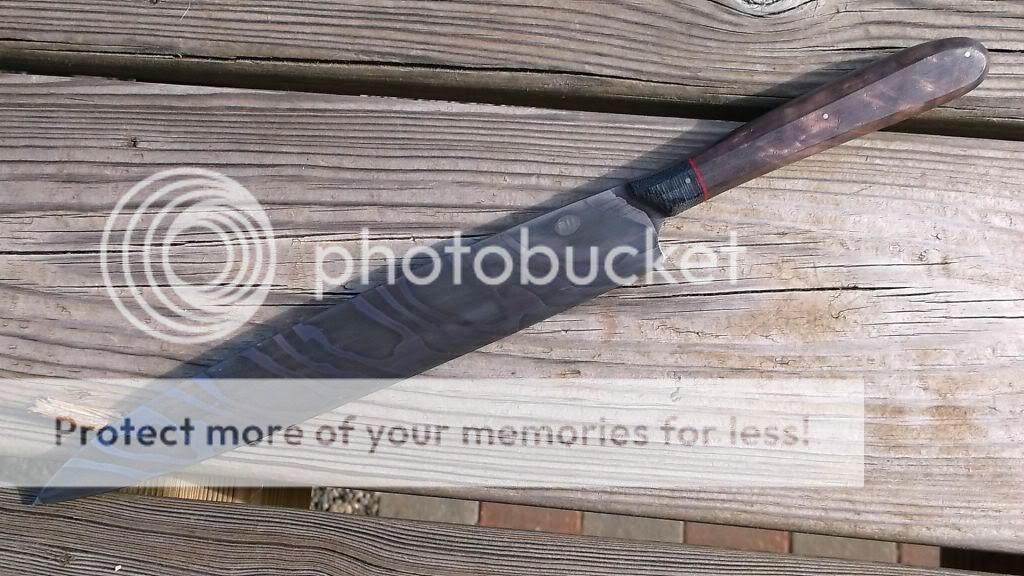

It would probably give me the same feeling as the first door dent in a new car.