I had a 1999 yr model heat N Glo with a stone surround that was practically worthless for heat. It would also occasionally and randomly just decide to fill the house with smoke, unrelated to wind. For the last few years I've looked for a viable alternative. At first searching for inserts.

After searching all over the Internet for a suitable insert I found none. So last week I removed the fireplace, completely. Leaving an 8' x 5' hole in the wall, a 10.5" pipe with standoffs inside sized for 8" chimney. The 8" stainless chimney was blued from heat exposure.

I found a suitable stove for a reasonable price in a USSC 2500.

I asked for a quote from the local stove guy for bricking the alcove and installing the stove and he wants $5k. That is pretty unreasonable imo, he is including $1200 in parts for a new insulated chimney and what I estimate to be about $100/hr.

I've elected to do it myself since I'm suddenly mostly unemployed thanks to the crash in oil prices and a sudden redefining of "your job is secure regardless of oil price". I've got the masonry and additional framing needed for the support box figured out. I do need some advice on the chimney though.

I see no problem running a 6" single wall chimney through the original 16' of 10.5". The original 8" pipe above a fireplace was much hotter (as evidenced by heat bluing of the stainless) than a 6" above a modern EPA stove will be. There was already single walled chimney there. There will be 6' of exposed stove pipe before the support box which will dissipate some additional heat The stand offs in the 10.5" are configured such that adequate air spacing around the 6" will be maintained. If I'm wrong, why? I can't justify the $1000 in additional parts and insulated chimney in my mind.

After searching all over the Internet for a suitable insert I found none. So last week I removed the fireplace, completely. Leaving an 8' x 5' hole in the wall, a 10.5" pipe with standoffs inside sized for 8" chimney. The 8" stainless chimney was blued from heat exposure.

I found a suitable stove for a reasonable price in a USSC 2500.

I asked for a quote from the local stove guy for bricking the alcove and installing the stove and he wants $5k. That is pretty unreasonable imo, he is including $1200 in parts for a new insulated chimney and what I estimate to be about $100/hr.

I've elected to do it myself since I'm suddenly mostly unemployed thanks to the crash in oil prices and a sudden redefining of "your job is secure regardless of oil price". I've got the masonry and additional framing needed for the support box figured out. I do need some advice on the chimney though.

I see no problem running a 6" single wall chimney through the original 16' of 10.5". The original 8" pipe above a fireplace was much hotter (as evidenced by heat bluing of the stainless) than a 6" above a modern EPA stove will be. There was already single walled chimney there. There will be 6' of exposed stove pipe before the support box which will dissipate some additional heat The stand offs in the 10.5" are configured such that adequate air spacing around the 6" will be maintained. If I'm wrong, why? I can't justify the $1000 in additional parts and insulated chimney in my mind.

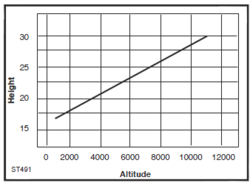

!! I would have never thought about altitude.

!! I would have never thought about altitude.