I just has about 4.5 cords of primarily oak with a little maple delivered this past weekend. I am very late with the firewood this year due to some large scale landscaping going on at my place. I had about 90 yards of fill dirt and county gravel brought in to level an area about 15 ft wide next to the driveway and also to build a level pad at the south end of the property for the firewood. On Thursday evening I had the last 10 yard load delivered and got the firewood pad levellled.

Just before sunset, Todd Fodor from Fodor Timber swung by with 2 large dump trucks with the split firewood. Delivered price is $150/cord split. I have added contact details for Fodor timber to the firewood price report on this site or do a google search for FODOR TIMBER, Grass Lake, MI. I recently bought a Bobcat B200 TLB to cover the multitude of tasks most people get compact utility tractors for, but this machine can lift a ton at the loader bucket and the backhoe will dig down 10 ft. I intend to move out into the mountains in Colorado in the next 18-24 months (just as soon as I can get out from under my current mortgage) and I figure building a home out in a relatively remote area is not something you can do by hiring contractors (at least not on my budget).

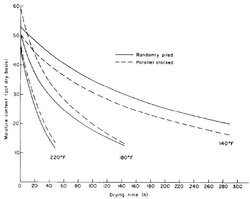

I then spent the majority of Saturday 4th of July moving the firewood onto the prepared pad. Because of space constraints and a large number of small neighborhood kids that crawl over everything I decided to make a woodpile instead of stacking. I put down a vapor barrier on the ground, and the surface still slopes downhill about 4" over 15 ft, so I think I will keep the bottom of the woodpile relatively dry. The pile itself is 20ft long at the base, 14 ft wide and 7ft high. I am still working out a "tentlike" cover, since my plan is for a primitive Solar Kiln to speed up the drying process. I have dark grey pvc coated tarps 12ft x 20ft long. The idea is to have a tubular structure to support the tarp about 1ft clear of the wood on all sides. Close most of the sides except for a space about 1sq foot at the peak on both sides. The sun should get the temperatures up to about 170F for a substantial part of the day. Fresh air can enter at the bottom and the system will keep almost all of the rain off the wood. I did this on a smaller scale last year with a "tent" I made using 2" PVC pipe and the same type of tarp. I had no wet wood at any time all season, and we had up to 2ft of snow in a single night at various times last year.

What was kind of amusing moving the wood with the loader was than even though the bucket holds 3/4 yard, I would take load after load and the pile from the dump trucks didn't appear to get any smaller, even though the "new" pile got bigger and bigger. At the end I had to raise the bucket about 11ft high to dump onto the top of the pile and load the last few face cord into the bucket by hand. I had a trailer load of seasoned wood left over from last season, and I would say that maybe 20% of the wood I bought this year was standing dead wood. The rest had been felled last year in September, but left in log form until april this year, before it was put through a firewood processor.

This year 2 of my regular firewood sources have suspended operations (I was getting slab wood for $10/trailer load and hardwood in rounds for $25/trailer load). So this is certainly the most expensive firewood so far, but still better than coal or corn. Corn is down to $3.50/bushel "market price" but the retail price in Michigan still seems to be $6.50/bushel ???? Tough times out there for a lot of folks from automotive companies and suppliers as well as the building industry.

Best of luck to you all.

Keith (near Napoleon, MI)

Just before sunset, Todd Fodor from Fodor Timber swung by with 2 large dump trucks with the split firewood. Delivered price is $150/cord split. I have added contact details for Fodor timber to the firewood price report on this site or do a google search for FODOR TIMBER, Grass Lake, MI. I recently bought a Bobcat B200 TLB to cover the multitude of tasks most people get compact utility tractors for, but this machine can lift a ton at the loader bucket and the backhoe will dig down 10 ft. I intend to move out into the mountains in Colorado in the next 18-24 months (just as soon as I can get out from under my current mortgage) and I figure building a home out in a relatively remote area is not something you can do by hiring contractors (at least not on my budget).

I then spent the majority of Saturday 4th of July moving the firewood onto the prepared pad. Because of space constraints and a large number of small neighborhood kids that crawl over everything I decided to make a woodpile instead of stacking. I put down a vapor barrier on the ground, and the surface still slopes downhill about 4" over 15 ft, so I think I will keep the bottom of the woodpile relatively dry. The pile itself is 20ft long at the base, 14 ft wide and 7ft high. I am still working out a "tentlike" cover, since my plan is for a primitive Solar Kiln to speed up the drying process. I have dark grey pvc coated tarps 12ft x 20ft long. The idea is to have a tubular structure to support the tarp about 1ft clear of the wood on all sides. Close most of the sides except for a space about 1sq foot at the peak on both sides. The sun should get the temperatures up to about 170F for a substantial part of the day. Fresh air can enter at the bottom and the system will keep almost all of the rain off the wood. I did this on a smaller scale last year with a "tent" I made using 2" PVC pipe and the same type of tarp. I had no wet wood at any time all season, and we had up to 2ft of snow in a single night at various times last year.

What was kind of amusing moving the wood with the loader was than even though the bucket holds 3/4 yard, I would take load after load and the pile from the dump trucks didn't appear to get any smaller, even though the "new" pile got bigger and bigger. At the end I had to raise the bucket about 11ft high to dump onto the top of the pile and load the last few face cord into the bucket by hand. I had a trailer load of seasoned wood left over from last season, and I would say that maybe 20% of the wood I bought this year was standing dead wood. The rest had been felled last year in September, but left in log form until april this year, before it was put through a firewood processor.

This year 2 of my regular firewood sources have suspended operations (I was getting slab wood for $10/trailer load and hardwood in rounds for $25/trailer load). So this is certainly the most expensive firewood so far, but still better than coal or corn. Corn is down to $3.50/bushel "market price" but the retail price in Michigan still seems to be $6.50/bushel ???? Tough times out there for a lot of folks from automotive companies and suppliers as well as the building industry.

Best of luck to you all.

Keith (near Napoleon, MI)