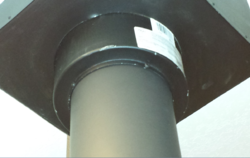

Have a 1975 Fisher Grandma with 6" OD connection. During remodel have replaced the chimney and ceiling box. The ceiling box is a new installed Selkirk 206424 . For stove pipe am using new single wall ICC 6" Ultra Black sections with a slip length . The only way the pipe fits on the stove and the ceiling box connection is with the stove pipe male ends pointing up. I am burning the stove this way currently. I understand this is not correct. I am trying to identify the correct adapters for the stove and ceiling box to make a correct installation with male ends pointing down all the way from the box connection to the stove connection.

I should mention , the old pipe and box (1975 install) was also installed incorrectly with males pointing up , burned 5 cords / year for 25 years , kept the pipe clean , and never had an issue with this bad configuration . Do I really need to pursue a correct pipe installation ?

I should mention , the old pipe and box (1975 install) was also installed incorrectly with males pointing up , burned 5 cords / year for 25 years , kept the pipe clean , and never had an issue with this bad configuration . Do I really need to pursue a correct pipe installation ?