I took my water sample this morning in the Garn and for the first time in the past year, I had floating white tiny particles on the surface of the water. Otherwise it was clear.

I inserted a new anode rod about 2 months ago...and it is clearly "active" as it looked all rough. I also added about 150-175 gallons of water at the time of adding the rod. Water was filter through the 5um filter as was the initial fill.

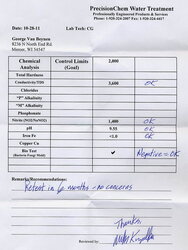

Water sample sent off to Precision today, so I will hear back soon. It's the usual six months sample.

Now the HX tubes are coated with a white material, always have been since the first few months, so I don't know if this white "particulates" are it flaking off or what. I did have a burn that got up to 210....maybe it broke free in some boil? Stupid me....to much wood.

Anyone ever see floating stuff on the water?

Thanks!

I inserted a new anode rod about 2 months ago...and it is clearly "active" as it looked all rough. I also added about 150-175 gallons of water at the time of adding the rod. Water was filter through the 5um filter as was the initial fill.

Water sample sent off to Precision today, so I will hear back soon. It's the usual six months sample.

Now the HX tubes are coated with a white material, always have been since the first few months, so I don't know if this white "particulates" are it flaking off or what. I did have a burn that got up to 210....maybe it broke free in some boil? Stupid me....to much wood.

Anyone ever see floating stuff on the water?

Thanks!

Were you able to reuse your gaskets?

Were you able to reuse your gaskets?