I don't trust moisture meters, never have. They are dependent entirely on industry established tables derived from the average resistivity of various wood species at various moisture contents. These tables don't take into account the differing methods for determining and expressing moisture content in wood, nor do they differentiate between woods grown in different areas, between sapwood and heartwood, etc. And heck, if you're new to all this, you probably aren't even sure of the species you are testing. The very best of them (Delmhorst is the industry standard) work reasonably well in most situations and with a bit of experience, but a pro model is close to 5 bills with the proper electrodes. Trusting your precious home (and maybe your lives) to the results of a $29 HF meter is pure folly AFAIC. So how can a new burner know with 100% certainty how much water is really in his firewood?

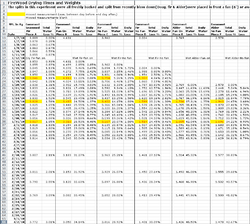

I decided to develop an easy as pie method to get the moisture content of your firewood without a shadow of doubt. The method involves a small saw, a cheap digital dietary scale and a microwave oven to dry the wood.

I took 13 samples of firewood from three different species, all having been subjected to different drying conditions. Using a small bow saw or carpenter's saw (I used my band saw), cut a slice about 1" thick from the center of the split or round is question. Use the center because that is likely to be the wettest part of the split. Weigh the slice of wood on the kitchen scale (use the "gram" setting) and record this weight onto the wood slice with a magic marker. I used a triple beam balance only because I was in the workshop. Accuracy to tenths of a gram aren't really important because we used such a big slice to begin with.

Take the wood slice into the kitchen and put in on several paper towels on the bottom of the microwave. Give 30 second blasts on high, rotating the slice in a new direction after each cycle. Water will be removed very rapidly at first. The microwave will get steamy inside for the first few cycles. After about 10 cycles, start weighing the slice after every cycle. Give it about a minute or two between cycles, and pay strict attention to how hot the wood is getting. Soon it will slow down its weight loss and eventually it will stop losing weight. Just like the folks using the scale for its original purpose.

Be very careful that you take your time with this or you will surely set your wood and microwave on fire. If that happens, your wife may never let you do this again. Plus, you will inadvertently remove at least some of the actual wood fiber content which will show your wood as having a slightly higher moisture content than it really had. I had 13 samples to do, so I rushed and fried a few of the the slices to some degree, but I don't think I really lost too much wood. I'll be more careful the next time.

I did all of the slices on one day, then weighed them the following morning. Most had actually gained a few grams of moisture, which is what I expected since even with the desert like conditions in a winter home, the air still has some moisture in it which the wood will reach equilibrium with.

When the wood stops decreasing in weight, it's time to re-weigh a final time and record the weight on the slice. I cooked them all again until they stopped losing weight, then put them in a 215ºF oven for about 8 hours. I needed to be sure that the microwave would remove all of the water. Most only lost a couple more grams of water after 8 hours in the oven (one lost nothing at all) confirming that the microwave drying methods works perfectly fine. With a bit of attention to detail and patience, all you will need is the microwave to get a result accurate enough for this purpose.

The wet looking spots on this hickory slice are actually sugars that have boiled out of the end grain and dried there. Has anyone ever tasted the sap that exudes from wet hickory splits? Yummy! Too bad no one taps these things for syrup.

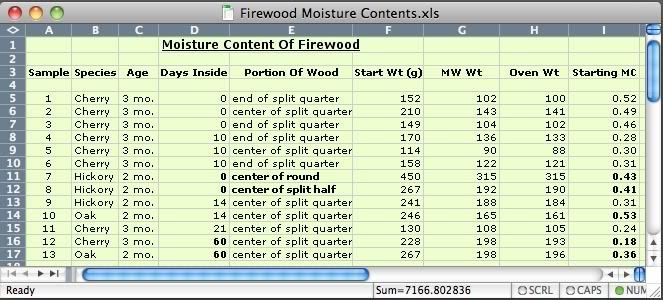

Now, just take the difference between the wet weight and the dry weight (which is the total amount of water removed), then divide this difference by the oven-dry weight to get the final ratio of water removed to oven-dry weight. Multiply by 100 to get the starting moisture content of the wood as it is most commonly expressed.

For example, the hickory round weighed 450 grams when I first cut it, and then 315 grams by the time all of the water was cooked out of it. 450g-315g=135g water removed. 135g/315g(oven-dry weight)=.429x100=42% MC.

Here's the final spreadsheet for the little project.

After I was done with all of the slices, I took them - all 4 1/2 pounds of them - and put them right on top of a nice bed of red-hot coals. Man, was that interesting!

I only hope no one gets the idea to microwave their wet wood instead of getting it to dry in other ways. For large scale drying in this manner, I would think one would need to use a macrowave instead. ;-)

I decided to develop an easy as pie method to get the moisture content of your firewood without a shadow of doubt. The method involves a small saw, a cheap digital dietary scale and a microwave oven to dry the wood.

I took 13 samples of firewood from three different species, all having been subjected to different drying conditions. Using a small bow saw or carpenter's saw (I used my band saw), cut a slice about 1" thick from the center of the split or round is question. Use the center because that is likely to be the wettest part of the split. Weigh the slice of wood on the kitchen scale (use the "gram" setting) and record this weight onto the wood slice with a magic marker. I used a triple beam balance only because I was in the workshop. Accuracy to tenths of a gram aren't really important because we used such a big slice to begin with.

Take the wood slice into the kitchen and put in on several paper towels on the bottom of the microwave. Give 30 second blasts on high, rotating the slice in a new direction after each cycle. Water will be removed very rapidly at first. The microwave will get steamy inside for the first few cycles. After about 10 cycles, start weighing the slice after every cycle. Give it about a minute or two between cycles, and pay strict attention to how hot the wood is getting. Soon it will slow down its weight loss and eventually it will stop losing weight. Just like the folks using the scale for its original purpose.

Be very careful that you take your time with this or you will surely set your wood and microwave on fire. If that happens, your wife may never let you do this again. Plus, you will inadvertently remove at least some of the actual wood fiber content which will show your wood as having a slightly higher moisture content than it really had. I had 13 samples to do, so I rushed and fried a few of the the slices to some degree, but I don't think I really lost too much wood. I'll be more careful the next time.

I did all of the slices on one day, then weighed them the following morning. Most had actually gained a few grams of moisture, which is what I expected since even with the desert like conditions in a winter home, the air still has some moisture in it which the wood will reach equilibrium with.

When the wood stops decreasing in weight, it's time to re-weigh a final time and record the weight on the slice. I cooked them all again until they stopped losing weight, then put them in a 215ºF oven for about 8 hours. I needed to be sure that the microwave would remove all of the water. Most only lost a couple more grams of water after 8 hours in the oven (one lost nothing at all) confirming that the microwave drying methods works perfectly fine. With a bit of attention to detail and patience, all you will need is the microwave to get a result accurate enough for this purpose.

The wet looking spots on this hickory slice are actually sugars that have boiled out of the end grain and dried there. Has anyone ever tasted the sap that exudes from wet hickory splits? Yummy! Too bad no one taps these things for syrup.

Now, just take the difference between the wet weight and the dry weight (which is the total amount of water removed), then divide this difference by the oven-dry weight to get the final ratio of water removed to oven-dry weight. Multiply by 100 to get the starting moisture content of the wood as it is most commonly expressed.

For example, the hickory round weighed 450 grams when I first cut it, and then 315 grams by the time all of the water was cooked out of it. 450g-315g=135g water removed. 135g/315g(oven-dry weight)=.429x100=42% MC.

Here's the final spreadsheet for the little project.

After I was done with all of the slices, I took them - all 4 1/2 pounds of them - and put them right on top of a nice bed of red-hot coals. Man, was that interesting!

I only hope no one gets the idea to microwave their wet wood instead of getting it to dry in other ways. For large scale drying in this manner, I would think one would need to use a macrowave instead. ;-)

)

)