This is the first in a series of threads I'm going to be starting trying to learn more about wood gasification boilers, since I'm planning to buy and install one (probably either a Tarm or an Eko) over the summer. Craig is always very helpful when I PM him with questions, but instead of bugging him exclusively, I figure it makes more sense to just put these questions out there and see what the collective intelligence comes up with.

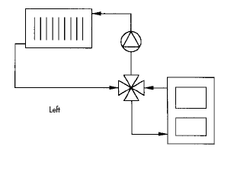

From what I've been able to learn so far, it's a good idea to have some type of water storage with a gasification system, both for the sake of efficiency and boiler maintenance. One option is to put a 500-800 gallon tank in the basement to store heat. An alternative would be to add a four-way mixing valve to my hydronic heating system, and essentially use the water in the system to store the heat, while it's heating the house. I think I have an ideal setup for that, but I'm not exactly clear on how a valve like that would work.

I'm guessing from the name that a mixing valve like this would mix cooler return water with hot supply water, thus putting somewhat cooler water into the hydronic distribution system more evenly, instead of hot bursts when the zones call for heat. But I'm not at all clear on how that would work when it comes to pumps, aquastats, thermostats, etc.

I have a big, old house with 15 cast iron radiators and three pump-driven zones. The main zone contains 11 of those 15 rads (the original farmhouse). The whole system must contain 300 or 400 gallons of water when you consider what the old gas-fired boiler holds in addition to the radiators. There are a couple of rooms where I'd like to put in even bigger radiators, which would add even more capacity. The system is currently heated with a non-gasifying wood boiler that transfers heat into the gas boiler vessel through a flat plate heat exchanger.

So, can somebody give me a simple explanation of how a four-way mixing valve would (should) work in this situation?

ps - Note to Marty S: Yes, you made me think.

From what I've been able to learn so far, it's a good idea to have some type of water storage with a gasification system, both for the sake of efficiency and boiler maintenance. One option is to put a 500-800 gallon tank in the basement to store heat. An alternative would be to add a four-way mixing valve to my hydronic heating system, and essentially use the water in the system to store the heat, while it's heating the house. I think I have an ideal setup for that, but I'm not exactly clear on how a valve like that would work.

I'm guessing from the name that a mixing valve like this would mix cooler return water with hot supply water, thus putting somewhat cooler water into the hydronic distribution system more evenly, instead of hot bursts when the zones call for heat. But I'm not at all clear on how that would work when it comes to pumps, aquastats, thermostats, etc.

I have a big, old house with 15 cast iron radiators and three pump-driven zones. The main zone contains 11 of those 15 rads (the original farmhouse). The whole system must contain 300 or 400 gallons of water when you consider what the old gas-fired boiler holds in addition to the radiators. There are a couple of rooms where I'd like to put in even bigger radiators, which would add even more capacity. The system is currently heated with a non-gasifying wood boiler that transfers heat into the gas boiler vessel through a flat plate heat exchanger.

So, can somebody give me a simple explanation of how a four-way mixing valve would (should) work in this situation?

ps - Note to Marty S: Yes, you made me think.