Framing in the tanks

- Thread starter huffdawg

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Gasifier

Minister of Fire

Good looking work Huff. Are you putting more insulation around them? Or just covering them up to make the place look pertty? Going to look good. Are you going to miss the fossil fuel bills? What was yours again? Propane? What kind of shape are you in for your wood supply for next year?

jebatty

Minister of Fire

goosegunner

Minister of Fire

How about some large PVC pipe sleeves? A short section of 6" sewer pipe extending from tank to outside box would work. Put a piece of Fiberglass insulation in it that you can pull out. You could also put a cap on it if you want to get fancy.

Valves you would need some bigger pvc.

gg

Valves you would need some bigger pvc.

gg

Thanx All ! I will be filling with cellulose or fiberglass not sure yet. When the tanks are hot you can still feel heat coming of them,but I think most of it is coming from the uninsulated pipes up there. I will try forming thin plywood to the tanks where the accesses will be . then spraying foam along the back edges where it meets the tanks to keep the insulation from falling into the access holes.

My wood supply is getting low right now I'll will have to buy a bit then start the wood accumulation project.

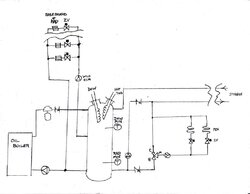

Here are some pics. of teeing in my house loads to the house loads loop. And the deactivation of my lpg. boiler :lol:

My wood supply is getting low right now I'll will have to buy a bit then start the wood accumulation project.

Here are some pics. of teeing in my house loads to the house loads loop. And the deactivation of my lpg. boiler :lol:

Attachments

goosegunner said:How about some large PVC pipe sleeves? A short section of 6" sewer pipe extending from tank to outside box would work. Put a piece of Fiberglass insulation in it that you can pull out. You could also put a cap on it if you want to get fancy.

Valves you would need some bigger pvc.

gg

Ya thats a good idea Goose . I might have some scrap pvc kicking around .

Noggah

New Member

goosegunner

Minister of Fire

Huff,

Your whole set up looks really nice. It is apparent you did a lot of planning and have an eye for detail.

What did your finished height of framing around tanks end up at?

gg

Your whole set up looks really nice. It is apparent you did a lot of planning and have an eye for detail.

What did your finished height of framing around tanks end up at?

gg

goosegunner said:Huff,

Your whole set up looks really nice. It is apparent you did a lot of planning and have an eye for detail.

What did your finished height of framing around tanks end up at?

gg

Thanx for the kudo's guys

I bought the boiler new 3 yrs. ago . Ive been building my house, shop , and suite now for 4-1/2 yrs. now. boiler system included. I strive hard to do thing right the first time but it doesn't always work out that way.Sometimes I think it would of been easier to just hire out the jobs pay the money and be done with it.

But am a very stubborn guy (my wife will attest to that) and I think I am capable of doing most anything with a little direction from guys that know and because I want it done my way . With the heating system, I repiped it twice because of a post by HR. He posted a pic. of his hydraulic separator then I ripped out my primary loop and installed a 150 gal. hydraulic separator because I thought it would work better for my application. Not that well planned but I think I like it now ,thats for sure.

If I had planned it right I would of had the storage tanks in the boiler room but I didn't build the suite sundeck big enough :lol:

The finished height of the tank framing was 9'-7-1/2" GG

Huff

goosegunner

Minister of Fire

I think I am going to be taking out my Primary Secondary manifold this year and putting in a buffer tank/Hydraulic Separator closer to my load. I think it would keep hot water closer to my heat loads for better response.

gg

gg

One thing I will be changing with the buffer tank in the future is the position of the supply for the shop infloor heating I think I should of drawn from the bottom and returned the bottom . Water is always hot enough down there anyways . Right now the supply is on the top third of the tank and the return s on the bottom.

HD

HD

goosegunner

Minister of Fire

huffdawg said:One thing I will be changing with the buffer tank in the future is the position of the supply for the shop infloor heating I think I should of drawn from the bottom and returned the bottom . Water is always hot enough down there anyways . Right now the supply is on the top third of the tank and the return s on the bottom.

HD

How close is your buffer tank to the storage?

gg

ewdudley

Minister of Fire

Except that water at the bottom of the buffer won't necessarily stay hot enough for long if low temperature loads return to the bottom of the buffer. If high temperature load activity happens to provide the necessary net flow to storage it would work fine, but only by luck.huffdawg said:One thing I will be changing with the buffer tank in the future is the position of the supply for the shop infloor heating. I think I should of drawn from the bottom and returned the bottom . Water is always hot enough down there anyways . Right now the supply is on the top third of the tank and the return s on the bottom.

What I came up with was to pull low temperature loads from the bottom of the buffer/hydronic separator and return to storage by connecting on either side of a check valve.

This results in a net flow from storage to the top of the buffer tank, where the high temperature loads get a shot at it.

I believe this guarantees that the low temperature loads will always get the lowest useful temperature water available, but at the same time it also guarantees that the low temperature loads will always get the heat they need independently of what the high temperature loads are doing.

--ewd

Attachments

My storage is about 25 ' of pipe lenth away GG

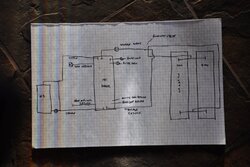

A rough drawing of Boiler circ,hydraulic separator,and storage piping

Here a link showing how my storage is piped to the hydraulic separator

https://www.hearth.com/econtent/index.php?ACT=24&fid=21&aid=64528_wvl96EvliChVquNy0zoZ&board_id=1

Huff

A rough drawing of Boiler circ,hydraulic separator,and storage piping

Here a link showing how my storage is piped to the hydraulic separator

https://www.hearth.com/econtent/index.php?ACT=24&fid=21&aid=64528_wvl96EvliChVquNy0zoZ&board_id=1

Huff

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 469

- Replies

- 2

- Views

- 270

- Replies

- 1

- Views

- 419

- Replies

- 1

- Views

- 611

I am very jealous.

I am very jealous.