Hope everyone is heating well without Saudi Oil this holiday season,

I have a Control wiring question for you GARN users out there. Hopefully "Hearterman" will add his experience and expertise to the answer as well.

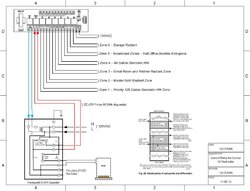

I am in the final phase of bringing my GARN up, and I am finally working out my controls for the system. My current House system is a Oil fired HW heater wired in a "Tankless" Configuration. The Boiler has a honeywell 8124A triple aquastat that controls the boiler, and sends back to my ZONE control board(ARGO ARM-6P) ZC-ZR. The End switch on the ARM-6P feeds X-X to T-T on the 8124A. I have a attached a jpg schematic of the current configuration for clarification.

What I would like to do, is use the X-X from the isolated switch on the ARM-6P as the master control for my GARN. I think that would require that I jumper ZC-ZR on the ARM, and run the GARN as a "COLD START" boiler. In a manual configuration, I would disable my oil-fired boiler.

For a more automatic control, my thinking is to use an aquastat in the GARN TANK to sense a low temperature condition, and then switch a set of relays that would "reconfigure" my existing oil boiler back to the "Tankless" mode, Disable the GARN control, and allow the Oil boiler to act as a back-up. On the GARN tank temperature rise above a setpoint, The relays would switch back to the GARN mode, and switch off the OIL boiler.

My final control solution would be to use a NON-Fossil controller to run everything once I get the kinks out.

So for now, I am just trying to get the GARN up and running, with the most basic of control. That would be disabling the Oil boiler completely with manual switches. I will then workout the backup/switch over control, and then finally switch everything over to the NF controller.

SO MY QUESTION: What do you think, will it work, or am I way off in the weeds somewhere? Comments, or suggestions are encouraged....I can stand the heat!

I have a Control wiring question for you GARN users out there. Hopefully "Hearterman" will add his experience and expertise to the answer as well.

I am in the final phase of bringing my GARN up, and I am finally working out my controls for the system. My current House system is a Oil fired HW heater wired in a "Tankless" Configuration. The Boiler has a honeywell 8124A triple aquastat that controls the boiler, and sends back to my ZONE control board(ARGO ARM-6P) ZC-ZR. The End switch on the ARM-6P feeds X-X to T-T on the 8124A. I have a attached a jpg schematic of the current configuration for clarification.

What I would like to do, is use the X-X from the isolated switch on the ARM-6P as the master control for my GARN. I think that would require that I jumper ZC-ZR on the ARM, and run the GARN as a "COLD START" boiler. In a manual configuration, I would disable my oil-fired boiler.

For a more automatic control, my thinking is to use an aquastat in the GARN TANK to sense a low temperature condition, and then switch a set of relays that would "reconfigure" my existing oil boiler back to the "Tankless" mode, Disable the GARN control, and allow the Oil boiler to act as a back-up. On the GARN tank temperature rise above a setpoint, The relays would switch back to the GARN mode, and switch off the OIL boiler.

My final control solution would be to use a NON-Fossil controller to run everything once I get the kinks out.

So for now, I am just trying to get the GARN up and running, with the most basic of control. That would be disabling the Oil boiler completely with manual switches. I will then workout the backup/switch over control, and then finally switch everything over to the NF controller.

SO MY QUESTION: What do you think, will it work, or am I way off in the weeds somewhere? Comments, or suggestions are encouraged....I can stand the heat!