garn install progress

- Thread starter wardk

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

bioman

Feeling the Heat

I went to every supplier in town , can't buy 1.25 pex, copper 7.41 per foot, last choice black iron, never done it, time to learn something new.Does anyone have experience with iron as far as measuring i.e. how far does the pipe go into the fitting.

Floydian

Feeling the Heat

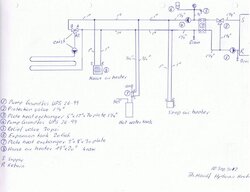

Now I will try to tackle this.View attachment 74218

Hmmm.... I don't think the Garn needs return water protection unlike the down drafters. But I am NOT a pro, so...

Noah

heaterman

Minister of Fire

Return water protection is absolutely not needed on a Garn and in fact will prematurely and unnecessarily dilute the storage temperature. Eliminate figure 2 in your drawing. Let that beast pound as much heat as it can into the heat exchanger. Reurn water protection is for mere mortal wood burners.

Piping from the HX to the Garn; Install a tee with a boiler drain and then a ball valve on both the supply and return. This will allow you to isolate the HX in the future should it need to be chemically cleaned.

RE: compensating for threads in steel pipe, 1/2" is going to be close for small diameter, about 3/4" for larger pipe like your 1-1/4". Usually you try to leave 2-3 imperfect threads showing, don't bury the thread in the fitting. I had a guy working for me once that figured everything should be tightened with a 36" pipe wrench. Needless to say he actually cracked a few 1/2 and 3/4" fitting. LOL

We like steel and use it nearly exclusively.

Piping from the HX to the Garn; Install a tee with a boiler drain and then a ball valve on both the supply and return. This will allow you to isolate the HX in the future should it need to be chemically cleaned.

RE: compensating for threads in steel pipe, 1/2" is going to be close for small diameter, about 3/4" for larger pipe like your 1-1/4". Usually you try to leave 2-3 imperfect threads showing, don't bury the thread in the fitting. I had a guy working for me once that figured everything should be tightened with a 36" pipe wrench. Needless to say he actually cracked a few 1/2 and 3/4" fitting. LOL

We like steel and use it nearly exclusively.

BoilerMan

Minister of Fire

Thanks Heaterman, I was looking for ball valves,Garn recommends using black iron for the first 4 to 6 feet then a dielectric coupler then a change of metals is ok. So far I have only found brass valves. What do you think? I have ordered most parts from OFS they were very helpfull switch the plate to a sidearm for dhw as I have very hard well water.Return water protection is absolutely not needed on a Garn and in fact will prematurely and unnecessarily dilute the storage temperature. Eliminate figure 2 in your drawing. Let that beast pound as much heat as it can into the heat exchanger. Reurn water protection is for mere mortal wood burners.

Piping from the HX to the Garn; Install a tee with a boiler drain and then a ball valve on both the supply and return. This will allow you to isolate the HX in the future should it need to be chemically cleaned.

RE: compensating for threads in steel pipe, 1/2" is going to be close for small diameter, about 3/4" for larger pipe like your 1-1/4". Usually you try to leave 2-3 imperfect threads showing, don't bury the thread in the fitting. I had a guy working for me once that figured everything should be tightened with a 36" pipe wrench. Needless to say he actually cracked a few 1/2 and 3/4" fitting. LOL

We like steel and use it nearly exclusively.

A friend is loaning me a threader "Ridged ratchet type" ,I have a chop saw for cutting I think will work, or would you get a proper cutter.tx

We used Rehah 1,25 insulated pipe.You can see it coming out of the ground in the last pic.Are you going to foam-in-trench the pipe?

TS

BoilerMan

Minister of Fire

OK now I get it, I thought you meant you couldn't get 1.25 pex for the burial run. Wow $74 for a stick of 1.25" copper

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M......

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M......

TS

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M......

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M......TS

heaterman

Minister of Fire

Thanks Heaterman, I was looking for ball valves,Garn recommends using black iron for the first 4 to 6 feet then a dielectric coupler then a change of metals is ok. So far I have only found brass valves. What do you think? I have ordered most parts from OFS they were very helpfull switch the plate to a sidearm for dhw as I have very hard well water.

A friend is loaning me a threader "Ridged ratchet type" ,I have a chop saw for cutting I think will work, or would you get a proper cutter.tx

You'll get a workout with the ratchet threader for sure but if the dies are in good shape it will cut a nice thread. Be generous with the cutting oil but try to get most of it out of the pipes before installing them.

Brass valves will be fine.

Do you insulate the black iron in the boiler room ?You'll get a workout with the ratchet threader for sure but if the dies are in good shape it will cut a nice thread. Be generous with the cutting oil but try to get most of it out of the pipes before installing them.

Brass valves will be fine.

OK now I get it, I thought you meant you couldn't get 1.25 pex for the burial run. Wow $74 for a stick of 1.25" copper

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M.

That was at a wholsale only plumbing supply, at 48 I would choose copper , soldering is easier than threading.OK now I get it, I thought you meant you couldn't get 1.25 pex for the burial run. Wow $74 for a stick of 1.25" copper

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M......

TS

We have three copper mines within 50 miles but all the ore goes to China to be processed. I guess I shouldn't groan my oldest son works at the nearest mine 44 per hr keeps his family fed.

BoilerMan

Minister of Fire

We have three copper mines within 50 miles but all the ore goes to China to be processed. I guess I shouldn't groan my oldest son works at the nearest mine 44 per hr keeps his family fed.

China is eating up all of our recources............so they can make the stuff we buy at WalMart for cheap.

I do love working with copper though, it's just plain beautiful if done well.

TS

First fire this weekend,filled with water and pre clean turned on the circ pump and lit the beast.Hard to believe it worked exactly like the manufacturer said it would,smoked a bit at first with paper and kindling but when the big wood caught it just roared no smoke. The beginning water temp 62 two and half hrs later 160 with seven large sticks of wood, it was a warm day and no load but still I was very impressed. I wish the secondary side of the was going as well, bought everything to do black iron but can't get a good thread on pipe. tried two threaders ,both left threads torn out , plumbery blames it on offshore steel. I guess I can return the black iron and go with copper it's only money.

OK now I get it, I thought you meant you couldn't get 1.25 pex for the burial run. Wow $74 for a stick of 1.25" copper

Holy schnikes Batman! It's $48 for 1.25" here at Lowe's and thats retail price type L (they don't carry M) The supply house wants more than that for type M......

TS

Good God, I thought I paid a lot a year ago for 1.25 L but it's up to 50 bucks a stick now? The one thing that I never went to the supply house for was pipe, both iron and copper, they simply could not match HD/Lowes and it was all the same brands. Heck, like you said why pay more for M when you can get L? Iron fitting on the other hand, I'll try never to buy another one at either of the big box stores...

I did notice that copper varied a lot from HD to Lowes though.

K

maple1

Minister of Fire

First fire this weekend,filled with water and pre clean turned on the circ pump and lit the beast.Hard to believe it worked exactly like the manufacturer said it would,smoked a bit at first with paper and kindling but when the big wood caught it just roared no smoke. The beginning water temp 62 two and half hrs later 160 with seven large sticks of wood, it was a warm day and no load but still I was very impressed. I wish the secondary side of the was going as well, bought everything to do black iron but can't get a good thread on pipe. tried two threaders ,both left threads torn out , plumbery blames it on offshore steel. I guess I can return the black iron and go with copper it's only money.

Between different fittings, nipples of various lengths up to 6", and off the shelf ready cut/threaded lengths in increments of 12" up to 5' long, I was able to do most of mine in iron, save short-ish final runs to tie into existing copper. Doesn't look as pretty as all copper, but it sure as heck saved money. Quite a difference in fitting prices, especially when you get into things like unions. At the start I considered getting or finding a threader, but settled on not cutting any threads and using off the shelf threaded parts.

BoilerMan

Minister of Fire

Good God, I thought I paid a lot a year ago for 1.25 L but it's up to 50 bucks a stick now? The one thing that I never went to the supply house for was pipe, both iron and copper, they simply could not match HD/Lowes and it was all the same brands. Heck, like you said why pay more for M when you can get L? Iron fitting on the other hand, I'll try never to buy another one at either of the big box stores...

I did notice that copper varied a lot from HD to Lowes though.

K

WARDK: Great news! Glad all went well and happy BTUs to YOU!!

Yeah if it's Iron and says China on it...........FORGET IT! Thinner walls, inconsistent threads, leak waiting to happen. Truse me on that one, that 36" cheater pipe on the wrench ain't no help either.... thats with Gasola and teflon tape, still leaked. Glad it was only the air test.

I went to the supply house and got Ward USA black fittings, and the heft, and the quality speak for themselves. I only used a few BI fittings 2" then bushed them down to 1-1/4" copper from there on out.

TS

A buddy came over yesterday and we looked at the threads, he gave it a try turns out the threads are damaged by the filings while reversing the threader off. We decided to give the BI another try ,rented large stand alone threader 'Rigid 300' it did not have to reverse off the threads,once set perfect threads every time. My friend offered to help and we did 120 ft of BI in an afternoon . Just goes to show the right tool for job. I only have a little final connections to do and we will see if the system works.Oct 2 and still have tomatoes no frost yet crazy.

maple1

Minister of Fire

Oct 2 and still have tomatoes no frost yet crazy.

That right there is the kind of thing that has me second guessing my whole project (although I always second guess everything I do). If the trend continues for very long, I would likely have been way further ahead just putting in a couple or three mini-split units. We definitely don't have the winters we used to have.

EDIT: On topic, I don't think my supplier has any BI that doesn't have China stamped on it. I haven't had any issues yet with it, altough I'm not threading it and there was that little welding issue a few months ago.

heaterman

Minister of Fire

Not limited to Chinese fittings. I had a US made Ward 1" 90* ell on a new gas line that had a pin hole in it a couple weeks ago. Of course it was in a spot that required a half hour of dis-assembly to replace. And also of course............it was a Monday.

maple1

Minister of Fire

SmokeEater

Feeling the Heat

I have been there and done that!! I found that the chinese fittings were often poorly threaded and even found one 1 1/4" 90 that was far greater than 90. I also found one hex bushing 1 1/2" to 1 1/4" that had a pinhole. I did have some trouble with some of the lengths I threaded with a manual Rigid set of dies. I thilnk the problem of tearing out threads had to do with the quality of the Lowe's BI I was using. The dies were new and adjusted properly.

Attachments

Had some leaks today some Bi some solder, the strange part is some of the solder leaks are on the old system haven't been touched for 5 yrs,

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 564

- Replies

- 5

- Views

- 2K

- Replies

- 15

- Views

- 1K

- Replies

- 53

- Views

- 2K

- Replies

- 13

- Views

- 1K