I have decided to open another thread on my garn installation. Thanks to so many of the participants, especially Jim K. and Slowzuki, I think that I can safely say that I am seeing light at the end of the tunnel. The details of my plight, of which I am the only one to blame, can be found in the thread, “Garn 1500 Arrived - Can’t afford to hook it up.” I won’t bother people here with my mistakes.

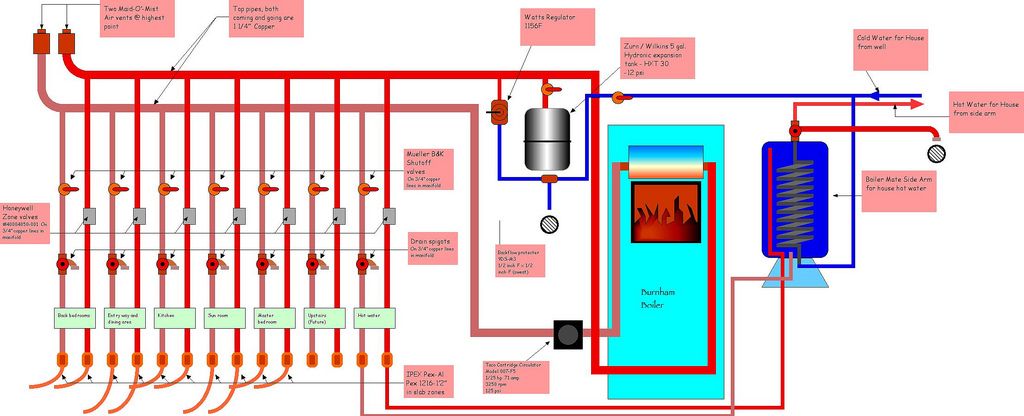

Okay, the existing boiler in my house is a three year old Burnham - Series 2 (Model B) Gas - Fired Boiler using propane (136 K btu). I have been unable to find any part numbers or serial numbers. The system includes a sidearm water heater and zoned in-floor radiant heat. The Pex in the floor is on 12” centers in the middle of 4” reinforced concrete. There is an insulating layer of Poly-iso foam between the slab and the ground. The house is three years old, built entirely by my wife and me.

The house is 2,700 s.f. It has a steel frame with 8” cavity walls blown solid with cellulose. I sheathed both inside and outside of the walls with 5/8 OSB. I have 39 dbl pane windows (low E) and have installed dbl walled polycarbonate interior storm windows on each. We have a Vermont Castings Reliant wood stove which we use to augment the home heating. We keep the thermostats at 60* year round. They are standard Honeywell (no frills) units. We have Ponderosa pine firewood for free from our sixty acres. We are at 7,300 feet, with temps between 90* and -15*. Snows are brutal when they come and many years we have 160”. We average between 1,400 and 1,500 gals. of propane for the entire year. Winter takes about 800 - 900 gals. of the total amount.

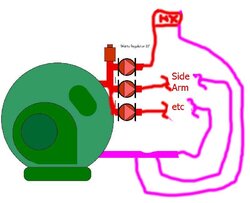

The design on the current radiant system hooked to the existing boiler is a question mark for a couple of reasons. The man who designed it did not put in mixing valves. The boiler appears to be set for a range of 128* to 168*. This is the drawing of the existing system. Forgive my homespun CAD work.

I have purchased a Garn 1500 and due to budget constraints must install it myself. I only set aside $2500 and my installer wants $8K. I am not being critical of the installer. He believes that it is a fair price, and it may be, but I do not have the cash.

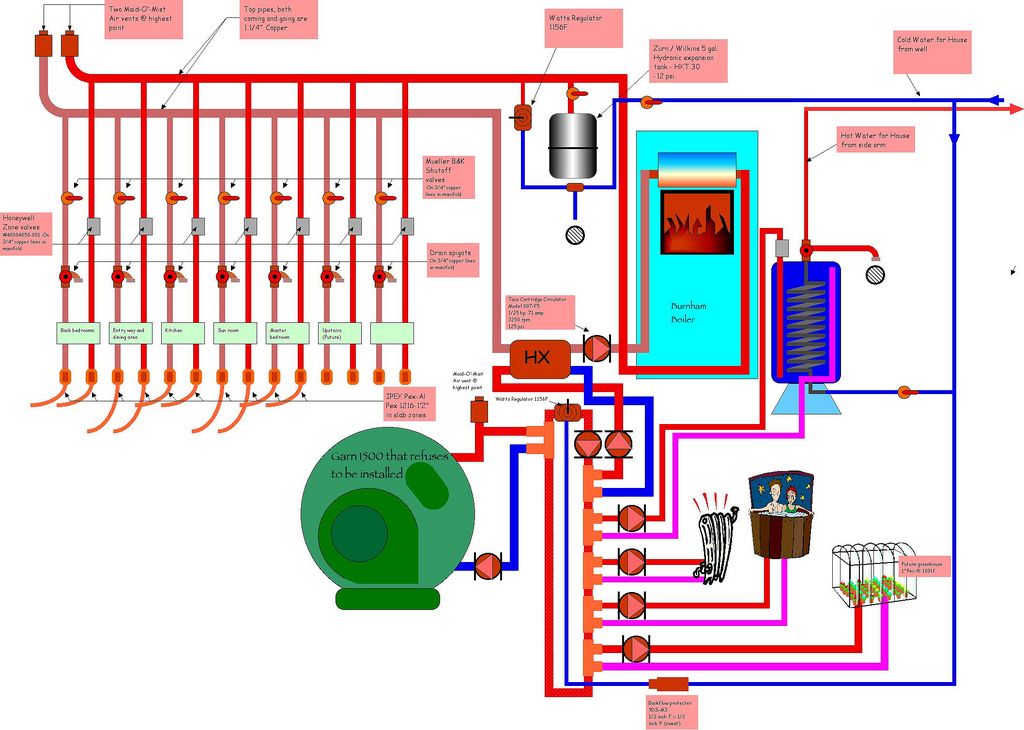

The Garn will be installed in my new boiler room that used to be my garage. The old boiler room is adjacent to the new one so I have only to cut through a single wall to hook into the Garn. No excavation will be required until some future project comes online. My hot tub and a single radiator will be added into a new room that was my second stall in the garage. Thanks to Jim K, I have now designed a system that just might actually work with efficiency. I am including it here.

My first question is how do I deal with the temperatures in my existing system which appear to be too high because of the lack of mixing valves? Should I place a mixing valve on each of the old zones? The rooms never over or under heat when we use our boiler.

The next question is about sizing on the primary loop on the Garn. Is 1¼” black steel sufficient?

This is probably too much for a first post. I am working on questions and an improved drawing of the new system for later.

Fire away!

Robert

Okay, the existing boiler in my house is a three year old Burnham - Series 2 (Model B) Gas - Fired Boiler using propane (136 K btu). I have been unable to find any part numbers or serial numbers. The system includes a sidearm water heater and zoned in-floor radiant heat. The Pex in the floor is on 12” centers in the middle of 4” reinforced concrete. There is an insulating layer of Poly-iso foam between the slab and the ground. The house is three years old, built entirely by my wife and me.

The house is 2,700 s.f. It has a steel frame with 8” cavity walls blown solid with cellulose. I sheathed both inside and outside of the walls with 5/8 OSB. I have 39 dbl pane windows (low E) and have installed dbl walled polycarbonate interior storm windows on each. We have a Vermont Castings Reliant wood stove which we use to augment the home heating. We keep the thermostats at 60* year round. They are standard Honeywell (no frills) units. We have Ponderosa pine firewood for free from our sixty acres. We are at 7,300 feet, with temps between 90* and -15*. Snows are brutal when they come and many years we have 160”. We average between 1,400 and 1,500 gals. of propane for the entire year. Winter takes about 800 - 900 gals. of the total amount.

The design on the current radiant system hooked to the existing boiler is a question mark for a couple of reasons. The man who designed it did not put in mixing valves. The boiler appears to be set for a range of 128* to 168*. This is the drawing of the existing system. Forgive my homespun CAD work.

I have purchased a Garn 1500 and due to budget constraints must install it myself. I only set aside $2500 and my installer wants $8K. I am not being critical of the installer. He believes that it is a fair price, and it may be, but I do not have the cash.

The Garn will be installed in my new boiler room that used to be my garage. The old boiler room is adjacent to the new one so I have only to cut through a single wall to hook into the Garn. No excavation will be required until some future project comes online. My hot tub and a single radiator will be added into a new room that was my second stall in the garage. Thanks to Jim K, I have now designed a system that just might actually work with efficiency. I am including it here.

My first question is how do I deal with the temperatures in my existing system which appear to be too high because of the lack of mixing valves? Should I place a mixing valve on each of the old zones? The rooms never over or under heat when we use our boiler.

The next question is about sizing on the primary loop on the Garn. Is 1¼” black steel sufficient?

This is probably too much for a first post. I am working on questions and an improved drawing of the new system for later.

Fire away!

Robert