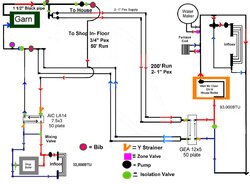

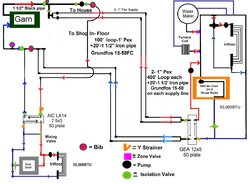

Well the Garn Barn is mostly ready and I am finally getting my design in shape and am anxious to order the parts.

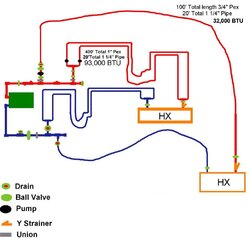

With all measuring complete the first loop, design load 93,000BTU to the house will be 400’ of tandem 1” PEX with 20’ of 1-1/2” black pipe. My calculations come to approximately 4.5gpm=5.29psi=12.2’ head on each 1” loop. When I size for one pump pushing both lines at 10gpm, I came to 15’ head. These include 1.4’ head for the GEA HX.

The second loop to the shop will be 100’ of ¾” PEX and 20’ of black pipe. With a design load of 32,000BTU I calculate 3.2gpm @ 6.5’ head. I plan to use one Grundfos 15-58FC .

I would like to use 2- Grundfos 15-58FC’s, one on each 1” PEX supply line (I could push 5gpm if necessary) to the house if necessary. This would allow 5 out of six pumps in the system to be 15-58’s with one 0011 on the in-floor loop. I will also have the ability to run one pump in the shoulder seasons and in the summer for domestic water and reduce energy consumption. I will use flanges with drains.

If I am installing nothing but brass ball valves and brass boiler drains on the black pipe is it necessary to install dielectric fittings?

I have attached two diagrams that I hope will help clarify my plan……….which is definitely open to new ideas and changes. I apologize for the format; I wish I had a program that would design with standardized symbols. The supply to the shop in the fittings diagram should be plumbed after the house supply to provide the hottest water to the house but the fittings should be very similar.

With all measuring complete the first loop, design load 93,000BTU to the house will be 400’ of tandem 1” PEX with 20’ of 1-1/2” black pipe. My calculations come to approximately 4.5gpm=5.29psi=12.2’ head on each 1” loop. When I size for one pump pushing both lines at 10gpm, I came to 15’ head. These include 1.4’ head for the GEA HX.

The second loop to the shop will be 100’ of ¾” PEX and 20’ of black pipe. With a design load of 32,000BTU I calculate 3.2gpm @ 6.5’ head. I plan to use one Grundfos 15-58FC .

I would like to use 2- Grundfos 15-58FC’s, one on each 1” PEX supply line (I could push 5gpm if necessary) to the house if necessary. This would allow 5 out of six pumps in the system to be 15-58’s with one 0011 on the in-floor loop. I will also have the ability to run one pump in the shoulder seasons and in the summer for domestic water and reduce energy consumption. I will use flanges with drains.

If I am installing nothing but brass ball valves and brass boiler drains on the black pipe is it necessary to install dielectric fittings?

I have attached two diagrams that I hope will help clarify my plan……….which is definitely open to new ideas and changes. I apologize for the format; I wish I had a program that would design with standardized symbols. The supply to the shop in the fittings diagram should be plumbed after the house supply to provide the hottest water to the house but the fittings should be very similar.